Abstract

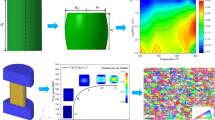

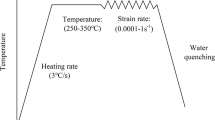

The isothermal compression tests were carried out to study the hot deformation behavior and microstructure evolution of Ti–19Al–22Mo alloy. The samples were deformed in the temperature range from 1100 to 1250 °C with an interval of 50 °C, strain rate ranging from 0.01 to 1 s−1 and the height reduction of 50% using Gleeble-3800 thermal–mechanical simulator. By using this experimental data an artificial neural network (ANN) model was developed and evaluated with unseen data. Further, the developed ANN model was used to predict flow stress correction from adiabatic heating at finer intervals of strain rates and temperatures. The predicted isothermal flow stress values were utilized to construct processing maps for Ti–19Al–22Mo alloy at true strain of 0.4 and 0.6. The maximum efficiency was noticed at 1100 °C with the strain rate of 0.01 s−1 associated with dynamic recrystallization and dynamic recovery. The deformation conditions of the instability domains in processing map showed wedge cracking and flow localization. Using the processing maps safe working parameters for hot deformation of Ti–19Al–22Mo alloy was identified.

Similar content being viewed by others

Change history

18 July 2019

Unfortunately, the acknowledgements were incomplete in the original version of this article.

References

K. Kothari, R. Radhakrishnan, N.M. Wereley, Prog. Aerosp. Sci. 55, 1 (2012)

F. Froes, C. Suryanarayana, D. Eliezer, J. Mater. Sci. 27, 5113 (1992)

G. Lütjering, J.C. Williams, Titanium (Springer, Berlin, 2007), pp. 1–379

M. Kimura, K. Hashimoto, H. Morikawa, Mater. Sci. Eng. A 152, 54 (1992)

C.Z. Qiu, L. Yong, L. Huang, W. Zhang, L. Bin, L. Bin, Trans. Nonferr. Met. Soc. China 22, 521 (2012)

M. Thomas, S. Naka, T. Khan, Mater. Trans.35, 787 (1994)

Y. Lu, J. Yamada, J. Nakamura, K. Yoshimi, H. Kato, J. Alloys. Compd. 696, 130 (2017)

M. Premkumar, A.K. Singh, Intermetallics 18, 199 (2010)

W. Sha, K.L. Edwards, Mater. Des. 28, 1747 (2007)

W.Y. Zhang, Appl. Mech. Mater. 20–23, 1211 (2010)

H.K.D.H. Bhadeshia, ISIJ Int. 39, 966 (1999)

N.S. Reddy, J. Krishnaiah, S.G. Hong, J.S. Lee, Mater. Sci. Eng. A 508, 93 (2009)

N.S. Reddy, B.B. Panigrahi, C.M. Ho, J.H. Kim, C.S. Lee, Comput. Mater. Sci. 107, 175 (2015)

A.K. Singh, S. Kumar, S. Banumathy, R.K. Mandal, Philos. Mag. 87, 5435 (2007)

X. Ma, W. Zeng, B. Xu, Y. Sun, C. Xue, Y. Han, Intermetallics 20, 1 (2012)

H. Zhou, Q. Peng, H. Yang, X. Zhou, R. Liu, Y. Peng, F. Zhong, J. Nucl. Mater. 448, 153 (2014)

J. Fan, H. Kou, M. Lai, B. Tang, H. Chang, J. Li, Rare Met. Mater. Eng. 43, 808 (2014)

W. Ke, M.Q. Li, Trans. Nonferr. Met. Soc. China 26, 1583 (2016)

T. Yan, E. Yu, Y. Zhao, Mater. Des. 50, 574 (2013)

Z. Liying, Y. Guanjun, G. Peng, M. Xiaonan, Z. Yongqing, Z. Lian, Rare Met. Mat. Eng. 39, 1505 (2010)

Y. Prasad, K. Rao, S. Sasidhar, Hot Working Guide: A Compendium of Processing Maps (ASM International, Geauga County, 2015), pp. 1–625

G.E. Dieter, H.A. Kuhn, S.L. Semiatin, Handbook of Workability and Process Design (ASM International, Geauga County, 2003), pp. 1–389

Y.V.R.K. Prasad, S. Sasidhara, Hot Working Guide: A Compendium of Processing Maps (ASM International, Geauga County, 1997), pp. 1–545

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, Y.V.R.K. Prasad, Mater. Sci. Eng. A 284, 184 (2000)

Y.V.R.K. Prasad, T. Seshacharyulu, Int. Mater. Rev. 43, 243 (1998)

S.L. Semiatin, V. Seetharaman, I. Weiss, JOM 49, 33 (1997)

D. Morris, D. Harries, J. Mater. Sci. 12, 1587 (1977)

G. Zhou, H. Ding, F. Cao, B. Zhang, J. Mater. Sci. Technol. 30, 217 (2014)

Acknowledgments

This study was supported by grants from the Fundamental Research Program (PNK5520/PNK5700) of the Korea Institute of Materials Science.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Narayana, P.L., Li, CL., Hong, JK. et al. Characterization of Hot Deformation Behavior and Processing Maps of Ti–19Al–22Mo Alloy. Met. Mater. Int. 25, 1063–1071 (2019). https://doi.org/10.1007/s12540-018-00237-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-018-00237-4