Abstract

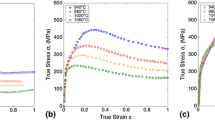

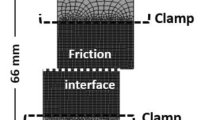

The mechanical properties of the Ni−Fe-based Alloy 718 depend very much on grain size, as well as the strengthening phases, γ’ and γ. The grain structure of the superalloy components is mainly controlled during thermo-mechanical processes by the dynamic, meta-dynamic recrystallization and grain growth. In this investigation, the evolution of the grain structure in the process of two-step blade forging was experimentally and numerically dealt with. The evolution of the grain structure in Alloy 718 during blade forging was predicted using a 2-DFE simulator with implemented constitutive models on dynamic recrystallization and grain growth. The comparison of the simulated microstructure with the actual grain structure of the forged parts validated the prediction of the grain structure evolution. The effect of dynamic recrystallization on the evolution of grain structure is highlighted in this article.

Similar content being viewed by others

References

G. Shen, J. Rollins, and D. Furrer,Superalloys 1996 (eds., R. D. Kissinger, D. J. Deye, D. L. Anton, A. D. Cetel, M. V. Nathal, T. M. Pollock, and D. A. Woodford), p. 613, TMS, Pennsylvania, USA (1996).

C. A. L. Bailer-Jones, T. J. Sabin, D. J. C. MacKay, and P. J. Withers,IPMM’ 97 (eds., T. Chandra, S. R. LeClair, J. A. Meech, B. Verma, M. Smith, and B. Balachandran), vol. 2, p. 913, Gold Coast, Australia (1997).

T. J. Sabin, C. A. L. Bailer-Jones, S. M. Roberts, D. J. C. MacKay, and P. J. Withers,THERMEC ’97 (eds. T. Chandra and T. Sakai), p. 1043 TMS, Wollongong, Australia (1997).

T. J. Sabin, S. M. Roberts, P. J. Withers, and C. A. L. Bailer-Jones,Proc. of the Int. Conf. on Forging and Related Technology (ICFT’98), p. 411, National Motorcycle Museum, Birmingham, UK (1998).

N. K. Park, J. T. Yeom, Y. S. Na, I. S. Kim, D. H. Kim, and S. J. Choe,Superalloys 718, 625, 706 and Various Derivatives (eds., E. A. Loria), p. 173, TMS, Pennsylvania, USA (1997).

G. Krauss,Deformation, Processing and Structure, ASM, St. Louis, Missouri (1982).

J. T. Yum and N. K. Park,J. Kor. Soc. Tech. Plasticity 6, 250 (1997).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Na, Y.S., Yeom, J.T., Park, N.K. et al. Prediction of microstructure evolution during high temperature blade forging of a Ni−Fe based superalloy, Alloy 718. Met. Mater. Int. 9, 15–19 (2003). https://doi.org/10.1007/BF03027224

Issue Date:

DOI: https://doi.org/10.1007/BF03027224