Abstract

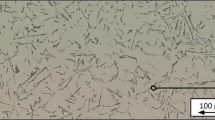

This paper presents the results of a project funded by the Edison Materials Technology Center to develop low-cost titanium aluminide automotive valves. In the course of the project, more than 800 valves were produced using several variations of the permanent-mold casting process. Applying pressure during solidification improved the casting fill; however, none of the permanent mold casting methods produced pore-free as-cast valves. The as-cast microstructures of the valves were much finer than investmentcast microstructures of similar section sizes. The room-temperature tensile properties of the permanent mold castings were superior to those of investment castings of a comparable section size.

Similar content being viewed by others

References

S. Hartfield-Wunsch et al., “Titanium Aluminide Automotive Engine Valves,”Gamma Titanium Aluminides, ed. Y-W Kim, R. Wagner, and M. Yamaguchi (Warrendale, PA: TMS, 1995), pp. 41–52.

D.E. Larsen, Jr., and D.A. Wheeler, “Investment Cast Gamma and XD™ Gamma Titanium Aluminide Components for Aerospace and Automotive Applications,”Investment Casting Institute: 42nd Annual Technical Meeting (Investment Casting Institute, 1994).

W.E. Dowling, Jr., et al. “TiAl-Based Alloys for Exhaust Valve Applications,” SAE paper 930630 (Warrendale, PA: SAE, 1993).

K. Maki et al., “Development of a High-Performance TiAl Exhaust Valve,” SAE paper 930303 (Warrendale, PA: SAE, 1996).

Y-W. Kim and D.M. Dimiduk, “Progress in the Understanding of Gamma Titanium Aluminides,”JOM, 43 (8) (1991), pp. 40–47.

D. Eylon, private communication (1993).

G.-X. Wang and M. Dahms, “Reactive Rowder Processing of Intermetallic Alloys Based on γ-TiAl”,Structural Intermetallics, ed. R. Darolia et al. (Warrendale, PA: TMS, 1993), pp. 215–222.

S.L. Semiatin, G.R. Cornish, and D. Eylon, “Hot-Compression Behavior and Microstructure Evolution of Pre-Alloyed Powder Compacts of a Near-γ Titanium Aluminide Alloy,”Materials Science and Engineering, A185 (1994), pp. 45–53.

G.E. Fuch, “Powder Metallurgy Processing of Ti-48Al-2Nb-2Cr (at%) Alloys,”MRS Symp. Proc., vol. 288 (Pittsburgh, PA: MRS, 1993), pp. 847–852.

Y. Mae, “Development of Titanium Die Casting,”Metallurgical Review of MMIJ, 8 (1) (1991), pp. 113–118.

S. Hurta et al., “Valves of Intermetallic γ-TiAl-Based Alloys: Processing and Properties,”Titanium’95, Proceedings of the Eighth World Conference on Titanium, ed. P.A. Blankinsop, W.J. Evans, and H.M. Flowers, London: Institute of Materials, 1995), pp. 97–104.

G. Colvin, U.S. patent 5,287,910.

Howmet, patent pending.

S.V. Ram and J.R. Barrett, “Investment Casting of Near-Net Shape Gamma Titanium Aluminide Low Pressure Turbine Blades,”Titanium ’95 Proceedings of the Eighth World Conference on Titanium, ed. P.A. Blankinsop, W.J. Evans, and H.M. Flowers, (London: Institute of Materials, 1995), pp. 90.

D. Eylon et al.EMTEC TR94-24 Part 1 (Kettering, OH: EMTEC, 1994), pp. 69–137.

Additional information

M.M. Keller earned her M.Sc. in materials engineering at the University of Dayton in 1993. She is currently a Ph.D. student in materials engineering. She is also a member of TMS.

P.E. Jones earned her M.Sc. in materials at the University of Dayton in 1993. She is currently a Ph.D. student in materials engineering. She is also a member of TMS.

W.J. Porter III earned his M.Sc. in materials engineering at the University of Dayton in 1990. He is currently project engineer at the University of Dayton Research Institute. He is also a member of TMS.

D. Eylon earned his D. Sc. in materials engineering at Technion, Haifa, Israel, in 1972. He is currently a professor of graduate materials engineering at the University of Dayton. He is also a member of TMS.

Rights and permissions

About this article

Cite this article

Keller, M.M., Jones, P.E., Porter, W.J. et al. The development of low-cost TiAl automotive valves. JOM 49, 42–44 (1997). https://doi.org/10.1007/BF02914683

Issue Date:

DOI: https://doi.org/10.1007/BF02914683