Abstract

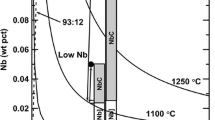

A detailed study of carbonitride precipitation in niobium/vanadium microalloyed steels is presented. A thermodynamic model is developed to predict the austenite/carbonitride equilibrium in the Fe−Nb-V-C-N system, using published solubility data and the Hillert/Staffansson model for stoichiometric phases. The model can be used to estimate equilibrium austenite and carbonitride compositions, and the amounts of each phase, as a function of steel composition and temperature. The model also provides a method to estimate the carbonitride solution temperatures for different steel compositions. Actual carbonitride precipitation behavior in austenite is then examined in two experimental 0.03Nb steels containing 0.05V and 0.20V, respectively. Samples were solution treated, rolled at 954°C (20 pct or 50 pct), held isothermally for times up to 10,000 seconds at 843°C, 954°C, or 1066°C, and brine quenched. The process of carbonitride precipitation in deformed austenite is followed by analytical electron microscopy (AEM) of carbon extraction replicas. Precipitates are observed at prior-austenite grain boundaries, and also within the grains (presumably at substructure introduced by the rolling deformation). Analysis of the grain-boundary and matrix precipitate compositions by AEM indicates that the grain-boundary precipitates are consistently richer in vanadium than the matrix precipitates, although compositional trends with holding time and temperature are similar for the two types of precipitates. The compositions of both the grain-boundary and matrix precipitates are not significantly influenced by the rolling reduction or the holding time at temperature. As predicted by the thermodynamic model, the precipitates become more vanadium-rich as the vanadium level in the steel is increased and as the temperature is reduced. The agreement between the measured and predicted precipitate compositions is quite good for the grain-boundary precipitates, although the matrix precipitates are consistently more niobium-rich than predicted by the model.

Similar content being viewed by others

References

Microalloying 75, Proceedings, Union Carbide Corporation, New York, NY, 1977.

The Hot Deformation of Austenite, J. B. Ballance, ed., TMS-AIME, New York, NY 1977.

Thermomechanical Processing of Microalloyed Austenite, A. J. DeArdo, G. A. Ratz, and P. J. Wray, eds., TMS-AIME, New York, NY, 1982.

S. S. Hansen, J. B. VanderSande, and Morris Cohen:Metall. Trans. A, 1980, vol. 11A, pp. 387–402.

R. Coladas, J. Masounave, and J. P. Bailon:The Hot Deformation of Austenite, TMS-AIME, New York, NY, 1977, pp. 341–77.

S. Yamamoto, C. Ouchi, and T. Osuka.Thermomechanical Processing of Microalloyed Austenite, TMS-AIME, New York, NY, 1982, pp. 613–38.

G. Fitzsimons, K. Tiitto, R. Fix, and A. J. DeArdo:Metall. Trans. A, 1984, vol. 15A, pp. 241–43.

H. L. Andrade, M. G. Akben, and J. J. Jonas:Metall. Trans. A, 1983, vol. 14A, pp. 1967–77.

J. G. Speer, S. Mehta, and S. S. Hansen:Scripta Metall., 1984, vol. 18, pp. 1241–44.

R. C. Hudd, A. Jones, and M. N. Kale:J. Iron Steel Inst., 1971, vol. 211, pp. 121–25.

H. Nordberg and B. Aronsson:J. Iron Steel Inst., 1968, vol. 206, pp. 1263–66.

W. Roberts, A. Sandberg, and T. Siwecki: Presented at the VANITEC Conference, Krakow, Poland, 1980, pp. D1–D12.

R. C. Sharma, V. K. Lakshmanan, and J. S. Kirkaldy:Metall. Trans. A, 1984, vol. 15A, pp. 545–53.

M. J. Crooks, A. J. Garratt-Reed, J. B. VanderSande, and W. S. Owen:Metall. Trans. A, 1981, vol. 12A, pp. 1999–2013.

S. Mehta, J. G. Speer, and S. S. Hansen:Analytical Electron Microscopy/ 1984, San Francisco Press, Inc., San Francisco, CA, 1984, pp. 173–76.

J. R. Michael:Materials Problem Solving with the Transmission Electron Microscope, Materials Research Society, Pittsburgh, PA, 1986, pp. 263–72.

D. C. Houghton, G. C. Weatherly, and J. D. Embury,Thermomechanical Processing of Microalloyed Austenite, TMS-AIME, New York, NY, 1982, pp. 267–92.

J. Strid and K. E. Easterling:Acta Metall., 1985, vol. 33, pp. 2057–74.

S. R. Keown and W. G. Wilson:Thermomechanical Processing of Microalloyed Austenite, TMS-AIME, New York, NY, 1982, pp. 343–56.

M. Grujicic, A. M. Sarosiek, L. Kaufman, and W. S. Owen:CALPHAD, 1985, vol. 9, pp. 117–28.

M. Grujicic, L. Kaufman, and W. S. Owen: private communication, Massachusetts Institute of Technology, Cambridge, MA, 1984.

J. G. Speer: Bethlehem Steel Corp. Internal Report R507-E1-A249, July 16, 1984.

L. Kaufman:CALPHAD, 1985, vol. 9, pp. 201–26.

Hugh Ford and J. M. Alexander:J. Inst. Metals, 1964, vol. 92, pp. 397–404.

G. Cliff and G. W. Lorimer:J. Micros., 1975, vol. 103, pp. 203–07.

D. B. Williams, D. E. Newbury, J. I. Goldstein, and C. E. Fiori:J. Micros., 1984, vol. 136, pp. 209–18.

N. J. Zaluzec:Analytical Electron Microscopy/1984, San Francisco Press, Inc., San Francisco, CA, 1984, pp. 279–84.

D. B. Williams:Practical Analytical Electron Microscopy in Materials Science, Philips Electronic Instruments, Mahwah, NJ, 1984, pp. 75–82.

S. P. Duckworth and T. N. Baker:Analytical Electron Microscopy/1984, San Francisco Press, Inc., San Francisco, CA, 1984, pp. 239–42.

H. J. Goldschmid:Interstitial Alloys, Plenum Press, New York, NY, 1967, pp. 88–253.

M. Hillert and L. I. Staffansson:Acta Chem. Scand., 1970, vol. 24, pp. 3618–26.

M. Temkin:Acta Physicochemica U.R.S.S., 1945, vol. 20, pp. 411–20.

P. Grieveson:Proc. Brit. Ceram. Soc., 1967, vol. 8, pp. 137–53.

W. Roberts and A. Sandberg: Swedish Institute for Metals Research Report No. IM-1489, Stockholm, 1980.

K. J. Irvine, F. B. Pickering, and T. Gladman:J. Iron Steel Inst., 1967, vol. 205, pp. 161–82.

K. Narita:Trans. I.S.I.J., 1975, vol. 15, pp. 145–51.

M. J. Frohberg and H. Graf:Stahl Eisen., 1960, vol. 80, pp. 539–41.

R. P. Smith:Trans. AIME, 1962, vol. 224, pp. 190–91.

V. K. Lakshmanan and J. S. Kirkaldy:Metall. Trans. A, 1984, vol. 15A, pp. 541–44.

R. P. Smith:Trans. AIME, 1966, vol. 236, pp. 220–21.

A. de Bon, J. Rofes-Vernis, and C. Rossard:Metal Science, 1975, vol. 9, pp. 36–40.

M. Raghavan:Metall. Trans. A. 1980, vol. 11A, pp. 993–99.

S. M. Merchant, M. R. Notis, and D. B. Williams:Metall. Trans. A, 1983, vol. 14A, pp. 1825–31.

W. C. Leslie, R. L. Rickett, C. L. Dotson, and C. S. Walton:Trans. ASM, 1954, vol. 46, pp. 1470–99.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Speer, J.G., Michael, J.R. & Hansen, S.S. Carbonitride precipitation in niobium/vanadium microalloyed steels. Metall Trans A 18, 211–222 (1987). https://doi.org/10.1007/BF02825702

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF02825702