Abstract

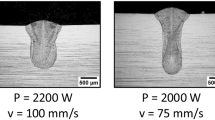

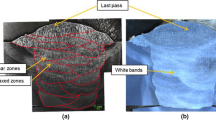

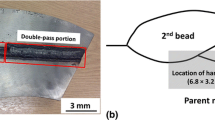

Previously developed techniques by the authors for the microstructural analysis of welds, that included the effects of both the growth crystallography and the weld pool shape, are applied to several cases involving the single-crystal electron beam welding of an Fe-15Ni-15Cr alloy. This evaluation of weld microstructures and associated dendritic growth patterns is based on a three-dimensional (3-D) geometrical analysis. The present study includes examination of the effects observed in overlapping, multipass autogenous welds and butt welds of two single crystals with different orientations, as well as effects due to variations in the welding speed. Weld pool shapes were found to change significantly with increasing welding speed—becoming narrower in cross section but more elongated in the welding direction. Additionally, all electron beam welds showed evidence of a plateau region in the center of the weld pool. The pool shapes, however, were found to be independent of the crystallographic orientation. Therefore, it is possible to extend the pool shape results to crystals welded in any orientation and even to polycrystals. The over-lapping multipass welds showed remarkable reproducibility from pass to pass and duplicated the structural patterns found in single-pass welds. The similarity in dendritic patterns within each pass indicated that the weld pool shapes were identical in all of the passes. The micro-structure of butt welds of two single crystals with different relative orientations showed a remarkable relationship to that associated with each individual crystallographic orientation, and the micro structure was, in effect, simply a composite of two single-pass microstructures. Additional microstructural details were also examined. The tendency toward branching of dendrites was associated with the transition from one dendrite growth orientation to another. It was also found that the nonpenetrating welds exhibited a small protrusion at the bottom of the weld. It is suggested that the modeling of weld pool shapes can be directly evaluated by comparing the predicted dendritic growth patterns based on the modeled shapes with the actual experimentally observed dendritic growth patterns.

Similar content being viewed by others

References

W.F. Savage, C.D. Lundin, and A.H. Aronson:Weld. J., 1965, vol. 44, pp. 175s-81s.

W.F. Savage and A.H. Aronson:Weld. J., 1966, vol. 45, pp. 85s-89s.

W.F. Savage, C.D. Lundin, and T.F. Chase:Weld. J., 1968, vol. 47, pp. 522s-26s.

J.M. Samuel: Ph.D. Thesis, Rensselaer Polytechnic Institute, Troy, NY, 1979.

M.C Flemings:Solidification Processing, McGraw-Hill, New York, NY, 1974, p. 159.

W. Kurz and D.J. Fisher:Fundamentals of Solidification, Trans Tech Publications Ltd., Aedermannsdorf, Switzerland, 1984, p. 240.

M. Rappaz and E. Blank:J. Cryst. Growth, 1986, vol. 74, pp. 67–76.

H. Nakagawa, M. Katoh, F. Matsuda, and T. Senda:Trans. Jpn. Weld. Soc, 1971, vol. 2 (1), pp. 1–9.

M. Kato, F. Matsuda, and T. Senda:Trans. Jpn. Weld. Soc, 1972, vol. 3 (1), pp. 59–68.

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner:Metall. Trans. A, 1989, vol. 20A, pp. 1125–38.

M. Rappaz, S.A. David, J.M. Vitek, and L.A. Boatner:Metall. Trans. A, 1990, vol. 21A, pp. 1767–82.

Author information

Authors and Affiliations

Additional information

Formerly Visiting Scientist, Solid State Division, Oak Ridge National Laboratory.

Rights and permissions

About this article

Cite this article

David, S.A., Vitek, J.M., Rappaz, M. et al. Microstructure of stainless steel single-crystal electron beam welds. Metall Trans A 21, 1753–1766 (1990). https://doi.org/10.1007/BF02672592

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02672592