Abstract

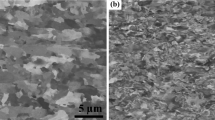

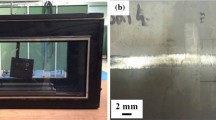

The present work addresses the microstructural and macrostructural development in multipass welded joints. It focuses on multiple thermal cycles induced by successive deposition of welding passes. The local welding-related thermal history was related in detail to the evolution of austenite grains during the manufacturing of two high-strength low alloy steel welds. The analytical Rosenthal thermal model was used to identify the thermal cycles experienced within typical weld metal regions. Selected heat cycles were applied to laboratory specimens, taken from the same weld metal, to investigate microstructural evolution during the welding process. Heat cycle experiments, involving full austenitization, showed the persistence of columnar zones resulting from a memory effect of the prior austenite grains during the reverse transformation. Intercritical heat cycles led to white etching, softer regions with high fractions of retained austenite. They also showed that the memory of austenite grains was actually stored in elongated retained austenite particles that remained after complete welding. This memory effect vanished under high peak temperatures (typically, 130 °C higher than Ac3); this was linked to a competition between growth and merging of elongated, intragranular retained austenite particles, and growth of equiaxed, intergranular austenite particles. Finally, a low peak temperature promoted refined, harder final microstructures.

Similar content being viewed by others

References

R. E. Dolby: Eng. Appl. Fract. Anal., 1980, pp. 117–34. https://doi.org/10.1016/B978-0-08-025437-1.50017-6

D.J. Abson and R.J. Pargeter: Int. Met. Rev., 1986, vol. 31(1), pp. 141–96. https://doi.org/10.1179/imtr.1986.31.1.141.

E. Keehan, L. Karlsson, H.O. Andrén, and L.E. Svensson: Weld. J., 2006, vol. 85(10), pp. 218–24.

E.S. Surian, N.M. Rissone, H.G. Svoboda, and L.A. Vedia: Weld. J., 2010, vol. 89(3), pp. 54–64.

L. Lan, C. Qiu, D. Zhao, X. Gao and L. Du: Mater. Sci. Eng, A, 2011, vol. 529, pp. 192-200. https://doi.org/10.1016/j.msea.2011.09.017

B.C. Kim, S. Lee, N.J. Kim, and D.Y. Lee: Metall. Trans. A., 1991, vol. 22(1), pp. 139–49. https://doi.org/10.1007/BF03350956.

S. Moeinifar, A.H. Kokabi, and H.M. Hosseini: Mater. Des., 2010, vol. 31(6), pp. 2948–55. https://doi.org/10.1016/j.matdes.2009.12.023.

D. Rosenthal: Trans. ASME., 1946, vol. 68, pp. 849–66.

N.N. Rykalin: Calculation of heat processes in welding, U.S.S.R, Moscow, 1960.

H. Arora, R. Singh and G. S. Brar: Meas. Control, 2019, vol. 52 (7-8), pp. 955–69. https://doi.org/10.1177/0020294019857747

M.J. Attarha and I. Sattari-Far: J. Mater. Process. Technol., 2011, vol. 211(4), pp. 688–94. https://doi.org/10.1016/j.jmatprotec.2010.12.003.

E. Keehan, J. Zachrisson, and L. Karlsson: Sci. Technol. Weld. Join., 2010, vol. 15(3), pp. 233–88. https://doi.org/10.1179/136217110X12665048207692.

G. Mao, R. Cao, C. Cayron, X. Mao, R. Logé, and J. Chen: Mater. Sci. Eng. A., 2019, vol. 744, pp. 671–81. https://doi.org/10.1016/j.msea.2018.12.035.

R.W. Fonda and G. Spanos: Metall. Mater. Trans. A., 2000, vol. 31(9), pp. 2145–53. https://doi.org/10.1007/s11661-000-0132-0.

M. Lord and G. Jennings: Svetsaren (Swed. Ed.), 1999, vol. 54 (1-2), pp. 53–58.

M.Q. Johnson, G.M. Evans, and G.R. Edwards: Metals., 1995, vol. 35(10), pp. 1222–31. https://doi.org/10.2355/isijinternational.35.1222.

B. Dixon and K. Hakansson: Weld. J., 1995, vol. 74(4), pp. 122–32.

X.F. Zhang, P. Han, H. Terasaki, M. Sato, and Y. Komizo: J. Mater. Sci. Technol., 2012, vol. 28(3), pp. 241–48. https://doi.org/10.1016/S1005-0302(12)60048-6.

Y. Kang, G. Park, S. Jeong, and C. Lee: Metall. Mater. Trans. A., 2018, vol. 49(1), pp. 177–86. https://doi.org/10.1007/s11661-017-4384-3.

R. Mythili, V.T. Paul, S. Saroja, M. Vijayalakshmi, and V.S. Raghunathan: J. Nucl. Mater., 2003, vol. 312(2–3), pp. 199–206. https://doi.org/10.1016/S0022-3115(02)01680-X.

M. Shome, O.P. Gupta, and O.N. Mohanty: Metall. Mater. Trans. A., 2004, vol. 34(13), pp. 985–96. https://doi.org/10.1007/s11661-004-1002-y.

G. Spanos, R.W. Fonda, R.A. Vandermeer, and A. Matuszeski: Metall. Mater. Trans. A., 1995, vol. 26(12), pp. 3277–93. https://doi.org/10.1007/BF02669455.

E.S. Surian and L.A. De Vedia: Weld. J., 1999, vol. 78, pp. 217–28.

M.M. Amrei, H. Monajati, D. Thibault, Y. Verreman, L. Germain, and P. Bocher: Mater. Charact., 2016, vol. 111, pp. 128–36. https://doi.org/10.1016/j.matchar.2015.11.022.

W. Liu, F. Lu, Y. Wei, Y. Ding, P. Wang, and X. Tang: Mater. Des., 2016, vol. 108, pp. 195–206. https://doi.org/10.1016/j.matdes.2016.06.102.

A.J.M. Gomes, J.C.F. Jorge, L.F.G. de Souza, and I.D.S. Bott: Mater. Sci. Forum., 2013, vol. 758, pp. 21–32. https://doi.org/10.4028/www.scientific.net/MSF.758.21.

A.P. Gerlich, H. Izadi, J. Bundy, and P.F. Mendez: Weld. J., 2014, vol. 93(1), pp. 15–22.

C.F. Jorge, J.L.D. Monteiro, and A.J. Gomes: J. Mater. Res. Technol., 2018, vol. 8(1), pp. 561–71. https://doi.org/10.1016/j.jmrt.2018.05.007.

Z. Zhang and R.A. Farrar: Weld. J., 1997, vol. 76(5), pp. 183–96.

G. Krauss JR: Acta Metall., 1963, vol. 11 (6), pp. 499–509. https://doi.org/10.1016/0001-6160(63)90085-3

H. Shirazi, G. Miyamoto, S.H. Nedjad, T. Chiba, and M.N. Ahmadabadi: Acta Mater., 2018, vol. 144, pp. 269–80. https://doi.org/10.1016/j.actamat.2017.10.068.

N. Nakada, T. Tsuchiyam, S. Takaki, and S. Hashizume: ISIJ Int., 2007, vol. 47(10), pp. 1527–32. https://doi.org/10.2355/isijinternational.47.1527.

L. Liu, Z.G. Yang, C. Zhang, and W.B. Liu: Mater. Sci. Eng. A., 2010, vol. 527(27–28), pp. 7204–09. https://doi.org/10.1016/j.msea.2010.07.083.

D. Brandl, M. Lukas, M. Stockinger, S. Ploberger, and G. Ressel: Mater. Des., 2019, vol. 176, 107841. https://doi.org/10.1016/j.matdes.2019.107841.

T. Hara, N. Maruyama, Y. Shinohara, H. Asahi, G. Shigesato, M. Sugiyama, and T. Koseki: ISIJ Int., 2009, vol. 49(11), pp. 1792–800. https://doi.org/10.2355/isijinternational.49.1792.

A.E. Nehrenberg: J. Met., 1950, vol. 2(1), pp. 162–74. https://doi.org/10.1007/BF03398992.

S. Matsuda and Y. Okamura: Trans. Iron Steel Inst. Jpn., 1974, vol. 14(5), pp. 363–68. https://doi.org/10.2355/isijinternational1966.14.363.

X. Zhang, G. Miyamoto, T. Kaneshita, Y. Yoshida, Y. Toji, and T. Furuhara: Acta Mater., 2018, vol. 154, pp. 1–13. https://doi.org/10.1016/j.actamat.2018.05.035.

J. Han and Y.K. Lee: Acta Mater., 2014, vol. 67, pp. 354–61. https://doi.org/10.1016/j.actamat.2013.12.038.

S. Watanabe and T. Kunitake: Trans. Iron Steel Inst. Jpn., 1976, vol. 16(1), pp. 28–35. https://doi.org/10.2355/isijinternational1966.16.28.

X. Zhang, G. Miyamoto, Y. Toji, and T. Furuhara: Metals., 2019, vol. 9(2), pp. 266–74. https://doi.org/10.3390/met9020266.

S.T. Kimmins and D.J. Gooch: Met. Sci., 1983, vol. 17(11), pp. 519–32. https://doi.org/10.1179/030634583790420484.

P. Promoppatum, S.C. Yao, P.C. Pistorius, and A.D. Rollett: Engineering., 2017, vol. 3(5), pp. 685–94. https://doi.org/10.1016/J.ENG.2017.05.023.

L. M. Dong, X. B. Qiu, T. Y. Liu, Z. Y. Lu, F. Fang and X. J. Hu: J. Mater. Sci. Eng. B, 2017, vol. 7 (11-12), pp. 258–67. https://doi.org/10.17265/2161-6221/2017.11-12.003

E. Keehan, L. Karlsson, H.O. Andrén, and H.K.D.H. Bhadeshia: Sci. Technol. Weld. Join., 2006, vol. 11(1), pp. 9–18. https://doi.org/10.1179/174329306X77849.

N. Jousset, PhD Thesis, Université PSL, Paris, France, 2022.

S. Zajac, V. Schwinn, and K.H. Tacke: Mater. Sci. Forum., 2005, vol. 500–501, pp. 387–94. https://doi.org/10.4028/www.scientific.net/MSF.500-501.387.

T. Shinozaki, Y. Tomota, T. Fukino, and T. Suzuki: ISIJ Int., 2017, vol. 57, pp. 533–39. https://doi.org/10.2355/isijinternational.ISIJINT-2016-557.

N. Nakada, R. Fukagawa, T. Tsuchiyama, S. Takaki, D. Ponge, and D. Raabe: ISIJ Int., 2013, vol. 53(7), pp. 1286–88. https://doi.org/10.2355/isijinternational.53.1286.

P. Song, W. Liu, C. Zhang, L. Liu, and Z. Yang: ISIJ Int., 2016, vol. 56(1), pp. 148–53. https://doi.org/10.2355/isijinternational.ISIJINT-2015-280.

D.W. Moon, R.W. Fonda, and G. Spanos: Weld. J., 2000, vol. 79(10), pp. 278–85.

S.J. Lee, J.S. Park, and Y.K. Lee: Scr. Mater., 2008, vol. 59(1), pp. 87–90. https://doi.org/10.1016/j.scriptamat.2008.02.036.

S.J. Lee and Y.K. Lee: Mater. Sci. Forum., 2005, vol. 475, pp. 3169–72. https://doi.org/10.4028/www.scientific.net/MSF.475-479.3169.

S. Yamamoto, H. Yokoyama, K. Yamada, and M. Niikura: ISIJ Int., 1995, vol. 35(8), pp. 1020–26. https://doi.org/10.2355/isijinternational.35.1020.

L. Lan, Z. Chang, and P. Fan: Metals., 2018, vol. 8(12), pp. 988–100. https://doi.org/10.3390/met8120988.

Acknowledgments

The authors greatly acknowledge the French National Association for Research and Technology (ANRT) for financial support under CIFRE Grant No. 2018/1249. The authors warmly thank Gérard Brabant (Centre des Matériaux) for his kind help and assistance with dilatometric tests.

Conflict of interest

The authors declare that they have no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jousset, N., Gaumé, M., Bridier, F. et al. Effect of the Thermal History on Macrostructure and Microstructure Development in High-Strength Steel Welds. Metall Mater Trans A 53, 2561–2576 (2022). https://doi.org/10.1007/s11661-022-06686-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06686-2