Abstract

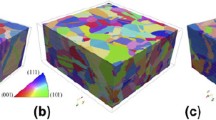

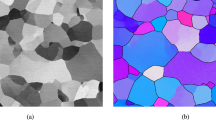

The intercrystalline structure distribution function (ISDF) describes the probability density for the occurrence of grain boundaries in the polycrystalline medium with five specified geometrical parameters: three describing intercrystalline lattice misorientation and two describing the orientation of the grain boundary plane. This paper extends the ISDF analysis to Bunge’s formalism which represents the distribution in terms of a series expansion of symmetric generalized spherical harmonics. An exemplary calculation of the ISDF is illustrated for alloy 304 stainless steel tubing. The results confirm the observation that gS3 and gS9 boundaries, arising from twinning, are prevalent in the structure. The distribution of twinning boundaries and other special boundaries is represented by Euler plots in the five geometrical parameters defining boundary structure. One remarkable feature of this material is a nearly isotropic distribution of boundary misorientation in the two parameters defining the boundary plane orientation. These results are compared with other published experimental data and theoretical calculations for the distribution of special boundaries.

Similar content being viewed by others

References

B.L. Adams:Metall. Trans. A, 1986, vol. 17A, pp. 2199–2207.

J.E. Hilliard:Trans. AIME, 1962, vol. 224, pp. 1201–11.

E. M. Philofsky and J.E. Hilliard:Quart. Appl. Math., 1969, vol. 27, pp. 79–85.

H. J. Bunge:Texture Analysis in Materials Science, Butterworth’s, London, 1982.

R. J. Roe:J. Appl. Phys., 1965, vol. 36, pp. 2024–31.

R. J. Roe:J. Appl. Phys., 1966, vol. 37, pp. 2069–72.

C.T. Young, J.H. Steele, Jr., and J.L. Lytton:Metall. Trans., 1973, vol. 4, pp. 2081–89.

P. Heilmann, W. A. T. Clark, and D. A. Rigney:Ultramicroscopy, 1982, vol. 9, pp. 365–72.

R. L. Burden, J. D. Faires, and A. C. Reynolds:Numerical Analysis, 2nd ed., Prindle, Weber & Schmidt, Boston, 1981, pp. 291–93.

D.G. Brandon:Acta Metall., 1966, vol. 14, p. 1479.

J. Don and S. Majumdar:Acta Metall., 1986, vol. 34, no. 5, pp. 961–67.

J. Zhao and B.L. Adams:Proc. Int. Conf. Fatigue, Corrosion Cracking, Fracture Mechanics, and Failure Analysis: The Mecha- nism of Fracture, V. S. Goel, ed., ASM, Metals Park, OH, 1986, p. 597–603.

R. Maurer and H. Gleiter:Scripta Metall., 1979, vol. 13, p. 61.

D. H. Warrington and M. Boon:Acta Metall., May 1975, vol. 23, pp. 599–606.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhao, J., Koontz, J.S. & Adams, B.L. Intercrystalline structure distribution in alloy 304 stainless steel. Metall Trans A 19, 1179–1185 (1988). https://doi.org/10.1007/BF02662578

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02662578