Abstract

A method is proposed for analyzing the relative energy distributions of grain boundaries in ultrafine-grained materials measured by grain boundary grooving using a scanning tunneling microscope. The grain boundary energy distribution in a grain boundary ensemble is considered as a superposition of individual distributions or populations, which can be identified by cluster analysis based on statistical criteria and each of which has its own average energy, variance, and share in the total distribution. The analysis is performed for 12Cr15Mn9NiCu steel with a coarse-grained structure in the as-received state and with an ultrafine-grained structure produced by hot helical rolling and subsequent cold rolling. It is shown that the number of boundary populations and their main characteristics revealed by clustering depend on the steel structure. The results of cluster analysis of experimental distributions are compared with the EBSD measurement data on grain boundary misorientation distributions. Discrepancy between the clustering results for the energy and misorientation distributions of grain boundaries is discussed taking into account the difference in the type of information obtained.

Similar content being viewed by others

REFERENCES

Valiev, R.Z. and Alexandrov, I.V., Nanostructured Materials Produced by Severe Plastic Deformation, M.: Logos, 2000.

Zhu, Y.T., Langdon, T.G., Valiev, R.Z., Semiatin, S.L., Shin, D.H., and Lowe, T.C., Ultrafine Grained Materials III, The Minerals, Metals & Materials Society, 2004. https://www.tms.org/pubs/Books/PDFs/01-5239/01-5239-0.pdf

Gleiter, H., Nanostructured Materials: Basic Concepts and Microstructure, Acta Mater., 2000, vol. 48, pp. 1–29. https://doi.org/10.1016/S1359-6454(99)00285-2

Baretzky, B., Baró, M.D., Grabovetskaya, G.P., Gubicza, J., Ivanov, M.B., Kolobov, Yu.R., Langdon, T.G., Lendvai, J., Lipnitskii, A G., Mazilkin, A.A., Nazarov, A.A., Nogués, J., Ovidko, I.A., Protasova, S.G., Raab, G.I., Révész, Á., Skiba, N.V., Sort, J., Starink, M.J., Straumal, B.B., Suriñach, S., Ungár, T., and Zhilyaev, A.P., Fundamentals of Interface Phenomena in Advanced Bulk Nanoscale Materials, Rev. Adv. Mater. Sci., 2005, vol. 9, pp. 45–108. http://eprints.soton.ac.uk/id/eprint/23812

Popov, V.V., Popova, E.N., Stolbovskiy, A.V., and Pilyugin, V.P., Thermal Stability of Nanocrystalline Structure in Niobium Processed by High Pressure Torsion at Cryogenic Temperatures, Mater. Sci. Eng. A, 2011, vol. 528, no. 3, pp. 1491–1496. https://doi.org/10.1016/j.msea.2010.10.052

Lu, K., Stabilizing Nanostructures in Metals Using Grain and Twin Boundary Architectures, Nat. Rev. Mater., 2016, vol. 1, pp. 1–13. https://doi.org/10.1038/natrevmats.2016.19

Kimura, Y., Inoue, T., Yin, F., and Tsuzaki, K., Inverse Temperature Dependence of Toughness in an Ultrafine Grain-Structure Steel, Science, 2008, vol. 320, pp. 1057–1060. https://doi.org/10.1126/science.1156084

Trusov, P.V., Sharifullina, E.R., and Shveykin, A.I., Multilevel Model for the Description of Plastic and Superplastic Deformation of Polycrystalline Materials, Phys. Mesomech., 2019, vol. 22, no. 5, pp. 402–419. https://doi.org/10.1134/S1029959919050072

Read, W.T. and Shockley, W., Dislocation Models of Crystal Grain Boundaries, Phys. Rev., 1950, vol. 78, no. 3, pp. 275–289. https://doi.org/10.1103/PhysRev.78.275

Rohrer, G.S., Grain Boundary Energy Anisotropy: A Review, J. Mater. Sci., 2011, vol. 46, pp. 5881–5895. https://doi.org/10.1007/s10853-011-5677-3

Maki, T., Morphology and Substructure of Martensite in Steels, Phase Transform. Steels, 2012, vol. 2, pp. 34–58. https://doi.org/10.1533/9780857096111.1.34

Nesterova, E.V., Rubtsov, A.S., Rybin, V.R., and Zolotorevsky, N.Yu., High-Angle Boundaries Formed during Phase Transformations, Poverkhn. Fiz. Khim. Mekh., 1982, no. 5, pp. 30–35.

Kronberg, M.L. and Wilson, F.N., Structure of High Angle Grain Boundaries, Trans. AIME, 1949, vol. 185, pp. 506–508.

Watanabe, T., Grain Boundary Engineering: Historical Perspective and Future Prospects, J. Mater. Sci., 2011, vol. 46, pp. 4095–4115. https://doi.org/10.1007/s10853-011-5393-z

Brandon, D.G., The Structure of High-Angle Grain Boundaries, Acta Metall., 1966, vol. 14, no. 11, pp. 1479–1484. https://doi.org/10.1016/0001-6160(66)90168-4

Liu, X., Choi, D., Beladi, H., Nuhfer, N.T., Rohrer, G.S., and Barmakc, K., The Five Parameter Grain Boundary Character Distribution of Nanocrystalline Tungsten, Scripta Mater., 2013, vol. 69, pp. 413–416. https://doi.org/10.1016/j.scriptamat.2013.05.046

Humphreys, F.J., Grain and Subgrain Characterisation by Electron Backscatter Diffraction: Review, J. Mater. Sci., 2001, vol. 36, pp. 3833–3854.

Morawiec, A., Method to Calculate the Grain Boundary Energy Distribution over the Space of Macroscopic Boundary Parameters from the Geometry of Triple Junctions, Acta Mater., 2000, vol. 48, pp. 3525–3532. https://doi.org/10.1016/S1359-6454(00)00126-9

Zaefferer, S.A., Critical Review of Orientation Microscopy in SEM and TEM, Cryst. Res. Technol., 2011, vol. 46, no. 6, pp. 607–628. https://doi.org/10.1002/CRAT.201100125

Herring, W.C., Surface Tension as a Motivation for Sintering, in The Physics of Powder Metallurgy, Kingston, W.E., Ed., New York: McGraw-Hill, 1951, pp. 143–178.

Haremski, P., Epple, L., Wieler, M., Lupetin, P., Thelen, R., and Hoffmann, M.J., A Thermal Grooving Study of Relative Grain Boundary Energies of Nickel in Polycrystalline Ni and in a Ni/YSZ Anode Measured by Atomic Force Microscopy, Acta Mater., 2021, vol. 214, p. 116936. https://doi.org/10.1016/j.actamat.2021.116936

Mullins, W.W., Theory of Thermal Grooving, J. Appl. Phys., 1957, vol. 28, pp. 333. https://doi.org/10.1063/1.1722742

Zimmerman, J., Sharma, A., Divinski, S.V., and Rabkin, E., Relative Grain Boundary Energies in Ultrafine Grain Ni Obtained by High Pressure Torsion, Scripta Mater., 2020, vol. 182, pp. 90–93. https://doi.org/10.1016/j.scriptamat.2020.03.008

Han, J., Vitek, V., and Srolovitz, D.J., Grain-Boundary Metastability and Its Statistical Properties, Acta Mater., 2016, vol. 104, pp. 259–273. https://doi.org/10.1016/j.actamat.2015.11.035

Olmsted, D.L., Foiles, S.M., and Holm, E.A., Survey of Computed Grain Boundary Properties in Face-Centered Cubic Metals: I. Grain Boundary Energy, Acta Mater., 2009, vol. 57, pp. 3694–3703. https://doi.org/10.1016/j.actamat.2009.04.007

Geels, K., Fowler, D., Kopp, W., and Rückert, M., Metallographic and Materialographic Specimen Preparation, Light Microscopy, Image Analysis and Hardness Testing, USA: ASTM Int., 2006.

Miyamoto, H., Corrosion of Ultrafine Grained Materials by Severe Plastic Deformation: An Overview, Mater. Trans., 2016, vol. 57, no. 5, pp. 559–572. https://doi.org/10.2320/matertrans.M2015452

Gupta, R.K. and Birbilis, N., The Influence of Nanocrystalline Structure and Processing Route on Corrosion of Stainless Steel: A Review, Corrosion Sci., 2015, vol. 92, pp. 1–15. https://doi.org/10.1016/j.corsci.2014.11.041

Balusamy, T., Kumar, S., and Sankara Narayanan, T.S.N., Effect of Surface Nanocrystallization on the Corrosion Behaviour of AISI 409 Stainless Steel, Corrosion Sci., 2010, vol. 52, pp. 3826–3834. https://doi.org/10.1016/j.corsci.2010.07.004

Zheng, Z.J., Gao, Y., Gui, Y., and Zhu, M., Corrosion Behaviour of Nanocrystalline 304 Stainless Steel Prepared by Equal Channel Angular Pressing, Corrosion Sci., 2012, vol. 54, pp. 60–67. https://doi.org/10.1016/j.corsci.2011.08.049

Chen, G., Gao, Y., Wu, S., and Hu, J., Corrosion Behavior of AISI 304 Austenitic Stainless Steel Fabricated by Equal-Channel Angular Pressing, Adv. Mater. Res., 2011, vol. 194–196, pp. 411–415. https://doi.org/10.4028/www.scientific.net/AMR.194-196.411

Schino, A.D. and Kenny, J.M., Effects of the Grain Size on the Corrosion Behavior of Refined AISI 304 Austenitic Stainless Steels, J. Mater. Sci. Lett., 2002, vol. 21, pp. 1631–1634. https://doi.org/10.1023/A:1020338103964

Schino, A.D. and Kenny, J.M., Effect of Grain Size on the Corrosion Resistance of a High Nitrogen-Low Nickel Austenitic Stainless Steel, J. Mater. Sci. Lett., 2002, vol. 21, pp. 1969–1971. https://doi.org/10.1023/A:1021625117639

Moura, V., Kina, A.Y., Tavares, S.S.M., Lima, L.D., and Mainier, F.B., Influence of Stabilization Heat Treatments on Microstructure, Hardness and Intergranular Corrosion Resistance of the AISI 321 Stainless Steel, J. Mater. Sci., 2008, vol. 43, pp. 536–540. https://doi.org/10.1007/s10853-007-1785-5

Jafari, E., Corrosion Behaviors of Two Types of Commercial Stainless Steel after Plastic Deformation, J. Mater. Sci. Technol., 2010, vol. 26(9), pp. 833–838. https://www.jmst.org/EN/Y2010/V26/I9/833

Solomon, N. and Solomon, I., Effect of Deformation-Induced Phase Transformation on AISI 316 Stainless Steel Corrosion Resistance, Eng. Fail. Analys., 2017, vol. 79, pp. 865–875. https://doi.org/10.1016/j.engfailanal.2017.05.031

Kumar, B.R., Mahato, B., and Singh, R., Influence of Cold-Worked Structure on Electrochemical Properties of Austenitic Stainless Steel, Metall. Mater. Trans. A, 2007, vol. 38, pp. 2085–2094. https://doi.org/10.1007/s11661-007-9224-4

Handwerker, C.A., Dynys, J.M., Cannon, R.M., and Coble, R.L., Dihedral Angles in Magnesia and Alumina: Distributions from Surface Thermal Grooves, J. Am. Ceram. Soc., 1990, vol. 73(5), pp. 1371–1377. https://doi.org/10.1111/j.1151-2916.1990.tb05207.x

Saylor, D.M. and Rohrer, G.S., Measuring the Influence of Grain-Boundary Misorientation on Thermal Groove Geometry in Ceramic Polycrystals, J. Am. Ceram. Soc., 1999, vol. 82(6), pp. 1529–1536. https://doi.org/10.1111/j.1151-2916.1999.tb01951.x

McLachlan, G. and Peel, D., Finite Mixture Models, New York: John Wiley & Sons, Inc., 2000.

Dempster, A., Laird, N., and Rubin, D., Maximum Likelihood from Incomplete Data via the EM Algorithm, J. Roy. Statist. Soc. B, 1977, vol. 39(1), pp. 1–38. https://www.jstor.org/stable/2984875

Wilde, G. and Divinski, S., Grain Boundaries and Diffusion Phenomena in Severely Deformed Material, Mater. Trans., 2019, vol. 60(7), pp. 1302–1315. https://doi.org/10.2320/matertrans.MF201934

Vaz, F.M. and Fortes, M.A., Grain Size Distribution: The Lognormal and the Gamma Distribution Functions, Scripta Metall., 1988, vol. 22, pp. 35–40. https://doi.org/10.1016/S0036-9748(88)80302-8

Bock, D., Velleman, P., De Veaux, R., and Bullard, F., Stats: Modeling the World, New York: Pearson, 2019.

Surikova, N.S., Vlasov, I.V., Narkevich, N.A., Gordienko, A.I., and Kuznetsov, P.V., Structure and Deformation Properties of Austenitic Stainless Steel, Phys. Met. Metallogr., 2020, vol. 121, no. 3, pp. 276–283.

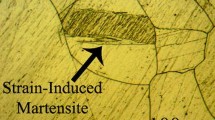

Shena, Y.F., Li, X.X., Sun, X., Wang, Y.D., and Zuo, L., Twinning and Martensite in a 304 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2012, vol. 552, pp. 514–522. https://doi.org/10.1016/j.msea.2012.05.080

Gong, N., Wu, H.B., Niu, G., Cao, J.M., and Zhang, D., Effect of Martensitic Transformation on Nano/Ultrafine-Grained Structure in 304 Austenitic Stainless Steel, J. Iron Steel Res. Int., 2017, vol. 24, pp. 1231–1237. https://doi.org/10.1016/S1006-706X(18)30022-0

Huang, X., Morito, S., Hansen, N., and Maki, T., Ultrafine Structure and High Strength in Cold-Rolled Martensite, Metall. Mater. Trans. A, 2012, vol. 43, p. 3517. https://doi.org/10.1007/s11661-012-1275-5

Sharma, N.K. and Shekhar, S., New Insights into the Evolution of Twin Boundaries during Recrystallization and Grain Growth of Low-SFE FCC Alloys, Mater. Charact., 2020, vol. 159, p. 110015. https://doi.org/10.1016/j.matchar.2019.110015

Zimmerman, J., Sharma, A., Divinski, S.V., and Rabkin, E., Relative Grain Boundary Energies in Ultrafine Grain Ni Obtained by High Pressure Torsion, Scripta Mater., 2020, vol. 182, pp. 90–93. https://doi.org/10.1016/j.scriptamat.2020.03.008

Tikhonova, M., Kaibyshev, R., Fang, X., Wang, W., and Belyakov, A., Grain Boundary Assembles Developed in an Austenitic Stainless Steel during Large Strain Warm Working, Mater. Charact., 2012, vol. 70, pp. 14–20. https://doi.org/10.1016/j.matchar.2012.04.018

Ikeda, K., Yamada, K., Takata, N., Yoshida, F., Nakashima, H., and Tsuji, N., Grain Boundary Structure of Ultrafine Grained Pure Copper Fabricated by Accumulative Roll Bonding, Mater. Trans., 2008, vol. 49(1), pp. 24–30. https://doi.org/10.2320/matertrans.ME200715

Morito, S., Saito, H., Ogawa, T., Furuhara, T., and Maki, T., Effect of Austenite Grain Size on Morphology and Crystallography of Lath Martensite in Low Carbon Steels, ISIJ Int., 2005, vol. 45(1), pp. 91–94. https://doi.org/10.2355/isijinternational.45.91

Morito, S., Adachi, Y., and Ohba, T., Morphology and Crystallography of Sub-Blocks in Ultra-Low Carbon Lath Martensite Steel, Mater. Trans., 2009, vol. 50(8), pp. 1919–1923. https://doi.org/10.2320/matertrans.MRA2008409

Morito, S., Tanaka, H., Konishi, R., Furuhara, T., and Maki, T., The Morphology and Crystallography of Lath Martensite in Fe-C Alloys, Acta Mater., 2003, vol. 51, pp. 1789–179. https://doi.org/10.1016/S1359-6454(02)00577-3

Takaki, S., Fukunaga, K., Syarif, J., and Tsuchiyama, T., Effect of Grain Refinement on Thermal Stability of Metastable Austenitic Steel, Mater. Trans., 2004, vol. 45(7), pp. 2245–2251. https://doi.org/10.2320/matertrans.45.2245

Funding

The work was carried out under the government statement of work for ISPMS SB RAS (Project FWRW-2021-0009) and the statement of work from the RF Ministry of Science and Higher Education (topic “Function”, No. 122021000035-6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizicheskaya Mezomekhanika, 2023, Vol. 26, No. 2, pp. 57–78.

Rights and permissions

About this article

Cite this article

Kuznetsov, P.V., Stolbovsky, A.V. & Belyaeva, I.V. Quantitative Characterization of Grain Boundaries in Ultrafine-Grained Austenitic Stainless Steel by Cluster Analysis. Phys Mesomech 26, 415–433 (2023). https://doi.org/10.1134/S1029959923040045

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959923040045