Abstract

Thermally sprayed coatings have a distinctive microstructure which can be described as “a three dimensional layered structure of discs which are interlaced to form a material of composite nature.≓ The coatings are normally greater than 25 (Ώm in thickness and can thus be described as bulk coatings. The minimum microstructural detail would be a single splat (ofter described as a lamella) which is about S (Ώm (approximately 0.0002 in.) in thickness and up to 80 Ώm (approximately 0.003 in.) in diameter.

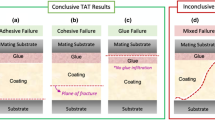

This paper focuses on methods used to define and measure the adhesion of coatings or deposits formed by thermal spray technology. The properties distinguished include strength and toughness. Measurements such as the tensile adhesion test (according to ASTM C633), the double cantilever beam test, and the scratch test are detailed to illustrate their relevance to present industrial practice. Acoustic emission studies have also been used to assess the “crack density function,” a product of the number of cracks and crack size. Indentation techniques have been used to determine the fracture toughness of coatings and to demonstrate that the material properties of coatings are anisotropic. These techniques, among others, may be used to gain a fundamental understanding of coating performance or for quality control. A further focus of this paper concerns the highly variable nature of the material properties of coatings. Such variation leads to poor reproducibility during service and can cause unpredictable performance. Therefore, a section is presented on the statistical analysis of thermal spray coatings, with particular reference to the Weibull distribution.

Similar content being viewed by others

References

T.N. Rhys Jones, Thermally Sprayed Coating Systems for Surface Protection and Clearance Control Application in Aero Engines,Surf. Coat. Technol., Vol 43/44,1990, p 402–415

K.T. Scott and R. Kingswell, Thermal Spraying,Advanced Surface Coatings, D.S. Rickerby and A. Mattews, Ed., Chapman and Hall, 1991, p 217–243

J.H. Zatt, A Quarter of a Century of Plasma Spraying,Annual Review of Material Science, Vol 13, R.A. Huggins, R.H. Bube, and D.A. Vermilyea, Ed., Annual Review Inc., 1983, p 9–42

C.C. Berndt, Ed.,Thermal Spray: International Advances in Coatings Technology, ASM International, 1992

C.C. Berndt and T.F. Bernecki, Ed.,Thermal Spray Coatings: Research, Design and Application, ASM International, 1993

S. Blum-Sandmeier, H. Eschnauer, P. Huber, and A.R. Nicoll, Ed.,Proc. 2nd Plasma-Technik-Symp., Plasma-Technik AG, Wohlen/Switzerland, HÄfliger Druck AG, Wettingen, 1991

L.E. Weiss, F.B. Prinz, D.A. Actams, and D.P. Siewiorek, Thermal Spray Shape Deposition,J. Therm. Spray Technol., Vol1(No. 3), 1992, p 231–237

K. Neufuss, B. Kolman, J. Dubsky, and P. Chraska, Plasma Sprayed Free-Standing Ceramic Parts,Proc. AustCeram 92 (Melbourne), 16-21Aug 1992, p 124–129

R. McPherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramic Coatings,Surf. Coat. Technol., Vol 39/40, 1989, p 173–181

V.H.S. Wilms, “The Microstructure of Plasma Sprayed Ceramic Coatings,≓ Ph.D. thesis, SUNY at Stony Brook, 1978

K.L. Mittal, “Adhesion Measurement: Recent Progress, Unsolved Problems, and Prospects,≓Adhesion Measurement of Thin Films, Thick Films, and Bulk Coatings, STP 640, K.L. Mittal Ed., ASTM,1978 p5–17

K.L. Mittal, Ed.,Adhesion Measurement of Thin Films, Thick Films,and Bulk Coatings, STP 640, ASTM, 1978

R.L. Patrick,Treatise on Adhesion and Adhesive, Vol 1, Marcel Dekker, 1967

≓Standard Terminology of Adhesives,≓ D 907-82,Annual Book of Standards, Vol 15.06, ASTM, 1985,p45–54

J. Comyn, Surface Treatment and Analysis for Adhesive Bonding,Int. J. Adhes. Adhes., Vol 10 (No. 3), 1990, p 161–165

A. Matting and H.-D. Steffens, Adherence and Coating by Arc Spraying and Flame Spraying, Parts 1-3,Metallwiss. Tech.,Vol. 17,1963,p583–593,905-922,1213-1230

M.D. Thouless, The Role of Fracture Mechanics in Adhesion,Mater. Res. Soc. Symp. Proc., Vol 119,1988, p 51–62

B.R.Lawn and T.R. Wilshaw,Fracture of Brittle Solids, Cambridge University Press, 1975

C.C. Berndt and R. McPherson, A Fracture Mechanics Approach to the Adhesion of Flame and Plasma Sprayed Coatings,Trans. Int. Eng., Vol 6 (No. 4), 1981, p 53–58

C.C. Berndt, Fracture Toughness Tests on Plasma Sprayed Coatings,Advances in Fracture Research, Vol 4, S.R. Valluri, D.M.R. Taplin, P. RamaRao, J.F. Knott, and R. Dubey, Ed., Pergamon Press, Oxford,1984, p 2545–2552

G.N. Heintze and R. McPherson, Fracture Toughness of Plasma Sprayed Zirconia Coatings,Surf. Coat. Technol., Vol 34,1988, p 15–23

C.C. Berndt, “The Adhesion of Flame and Plasma Sprayed Coatings,≓Ph.D. thesis, Monash University, Clayton, Victoria, Australia, 1980

P. Ostojic, “The Adhesion of Thermally Sprayed Coatings,≓ Ph.D. thesis,Monash University, Clayton, Victoria, Australia, 1986

K.L. Mittal, Selected Bibliography on Measurement of Films and Coatings,J. Adhes. Sci. Technol.,Vol 1(No. 3), 1987,p247–259

D.S. Rickerby, A Review of the Methods for the Measurement of Coating-Substrate Adhesion,Surf. Coat. Technol, Vol 36,1988, p 541–557

S.J. Bull and D.S. Rickerby, Evaluation of Coatings,Br. Ceram. Trans.J., Vol 88,1989, pi 77–183

P.R. Chalker, S.J. Bull, and D.S. Rickerby, A Review of the Methods for the Evaluation of Coating-Substrate Adhesion,Mater. Sci. Eng., VolA140,1991, p 583–592

B.A. Lyashenko, V.V. Rishin, V.G. Zil’berberg, and S.Yu. Sharivker,Strength of Adhesion Between Plasma-Sprayed Coatings and the BaseMetal,Sov. Powder Metall. Met. Ceram., Vol 8,1969, p 331–334

B.M. Zakharov, M.G. Trofimov, L.I. Guseva, Y.I. Golovkin, A.A. Kononov, and V.V. Vinokurova, Bond Strength of Coatings Applied by the Flame Plating Technique,Sov. Powder Metall. Met. Ceram., Vol 9,1970, p 925–929

W.E. Stanton, The Mechanical Properties of Sprayed Metals for Engineering,7th Int. Metal Spraying Con/., The Welding Institute, Cambridge,U.K., 1974, p 157–164,312-314

T. Suhara, K. Kitajima, and S. Fukada, Coatings by Wire Explosion Spraying—Properties and Applications,7th Int. Metal Spraying Conf, The Welding Institute, Cambridge, U.K., 1974, p 179–184

N.N Rykalin, Plasma Engineering in Metallurgy and Inorganic Materials Technology,Pure Appl. Chem., Vol 48,1976, p 179–194

V.E. Belashchenko and Y.B. Chernyak, Stochastic Approach to the Modeling of Thermal Spray Coating Formation,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 43–437

R.L. Apps, New Developments in Ceramics and Coatings,Chem. Eng. (UK), Vol 292,1974, p 769–773

V. Wilms and H. Herman, Plasma Spraying of A12O3 and AI2O3-Y2O3,Thin Solid Films, Vol 39,1976, p 251–262

T.J. Steeper, D.J. Varacalle, G.C. Wilson, W.L. Riggs II, A.J. Rotolico, and J.E. Nerz, A Design of Experiment Study of Plasma Sprayed Alumina-Titania Coatings,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 415-420

C.C. Berndt, Tensile Adhesion Testing Methodology for Thermally Sprayed Coatings,.J. Mater. Eng., Vol 12,1990, p 151–158

Y. Shimizu, M. Sato, M. Kobayashi, and K. Maeda, Effect of Test Specimen Size upon Adhesive Strength of Flame Sprayed Coatings,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 257–262

W. Han, E.F. Rybicki, and J.R. Shadley, An Improvement Specimen Geometry for ASTM C633-79 to Estimate Bond Strength of Thermal Spray Coatings,J. Therm. Spray Technol, Vol 2 (No. 2), 1993, p 145–150

W. Han, E.F. Rybicki, and J.R. Shadley, Application of Fracture Mechanics to the Interpretation of Bond Strength Data from ASTM Standard C633-79,J Therm. Spray Technol, Vol2(No. 3), 1993,p235–241

G.E. Dieter, inMechanical Metallurgy, McGraw-Hill, 1988, p 348–374

F.J. Hermanek, Determining the Adhesive/Cohesive Strength of Thin Thermally Sprayed Deposits,Weld. J., Vol 57,1978, p 31–35

C.C. Berndt, Tensile Adhesion Test Measurements on Plasma-Sprayed Coatings,Advances in Fracture Research, Vol 4, S.R. Valluri, D.M.R. Taplin, P. Rama Rao, J.F. Knott, and R. Dubey, Ed., Pergamon Press, Oxford, 1984, p 2553–2559

P.F. Becher and W.L. Newell, Adherence-Fracture of Glass-Bonded Thick-Film Conductor: Effect of Firing Conditions,J. Mater. Sci., Vol 12,1977, p 90–96

P.F. Becher, W.L. Newell, and S.A. Halen, Application of Fracture Mechanics to the Adherence of Thick Films and Ceramic Braze Joints,Fracture Mechanics of Ceramics, Vol III, R.C. Bradt, D.P.H. Hassel-man, and F.F. Lange, Ed., Plenum Press, 1978, p 463–471

W.D. Bascom and J.L. Bitner, AFracture Approach to Thick Film Adhesion Measurements,J. Mater. Sci., Vo1 12, 1977, p 1401–1410

S. Mostovoy, P.B. Crosley, and E.J. Ripling, Use of Crack-Line-Loaded Specimens for Measuring Plane-Strain Fracture Toughness,J. Mater.,Vol 2,1967, p 661–681

G.N. Heintze and R. McPherson, A Further Study of the Fracture Toughness of Plasma-Sprayed Zirconia Coatings,Surf. Coat. Technol.,Vol 36,1988,p125–132

J.O. Outwater and D.J. Gerry, On the Fracture Energy, Rehealing Velocity and Refracture Energy of Cast Epoxy Resin,J. Adhes., Vol 1, 1969, p 290–298

J.A. Kies and A.B.J. Clark, Fracture Propagation Rates and Times to Fail Following Proof Stress in Bulk Glass,Fracture 1969, PX. Pratt,Ed., Chapman and Hall, London, 1969, p 483–491

M.K. Ferber and S.D. Brown, Delayed Failure of Plasma-Sprayed AI2O3 Applied to Metallic Substrates,J. Am. Ceram. Soc., Vol 64 (No.12), 1981, p 737–743

L.C. Cox, The Four-Point Bend Test as a Tool for Coating Characterization,Surf. Coat. Technol, Vol 36,1988, p 807–815

S.J. Howard and T.W. Clyne, Interfacial Fracture Toughness of Vacuum-Plasma-Sprayed Coatings,Surf. Coat. Technol, Vol 45, 1991, p333–342

A.G. Evans, Fracture Mechanics Determinations, Fracture Mechanics of Ceramics, Vol 1, R.C.Bradt, D.P.H. Hasselman, and F.F.Lange, Ed., Plenum Press, 1974, p 17–48

P. Benjamin and C. Weaver, Measurement of Adhesion of Thin Film,Proc. R. Soc. (London) A, Vol 254,1960, p 163–176

A.J. Perry, J. Valli, and P.A. Steinmann, Adhesion Scratch Testing: A Round-Robin Experiment,Sur. Coat. Technol, Vol 36, 1988, p 559–575

C. Julia-Schmutz and H.E. Hintermann, Microscratch Testing to Characterize the Adhesion of Thin Layers,Surf. Coat. Technol, Vol 48,1991,p1–6

P.J. Burnett and D.S. Rickerby, The Relationship Between Hardness and Scratch Adhesion,Thin Solid Films, Vol 154,1987, p 403–416

S.J. Bull, D.S. Rickerby, A. Matthews, A. Leyland, A.R. Pace, and J. Valli, The Use of Scratch Adhesion Testing forthe Determination of Interfacial Adhesion: The Importance of Frictional Drag,Surf. Coat. echnol, Vol 36,1988, p 503–517

J. Sekler, P.A. Steinmann, and H.E. Hintermann, The Scratch Test: Different Critical Load Determination Techniques,Surf. Coat. Technol,Vol 36,1988, p 519–529

S.J. Bull, Failure Modes in Scratch Adhesion Testing,Surf. Coat. Technol, Vol 50,1991, p 25–32

D.K. Das, M.P. Srivastava, S.V. Joshi, and R. Sivakumar, Scratch Adhesion Testing of Plasma-Sprayed Yttria-Stabilized Zirconia Coatings,Surf. Coat. Technol, Vol 46,1991,p 331–345

C.W. Anderson and K.H. Heffner, Precision Gas Bearing Plasma Sprayed Aluminum Oxide Coating Characterization,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 695–704

M. Gudge, D.S. Rickerby, R. Kingswell, and K.T. Scott, Residual Stress in Plasma Metallic and Ceramic Coatings,Thermal Spray Research and Application, I.V. Bernecki, Ed., ASM International, USA, 1991, p 331–337

E. Lopez, F. Beltzung, and G. Zambelli, Measurement of Cohesion and Adhesion Strengths in Alumina Coatings Produced by Plasma Spraying,J. Mater. Sci. Lett., Vol 8,1989, p 346–348

F. Beltzung, G. Zambelli, E. Lopez, and A.R. Nicoll, Fracture Toughness Measurement of Plasma Sprayed Ceramic Coatings,Thin Solid Films, Vol 181,1989, p 407–415

M.J. Noone and R.L. Mehan, Observation of Crack Propagation in Polycrystalline Ceramics and Its Relationship to Acoustic Emission,Fracture Mechanics of Ceramics, Vol 1, R.C. Bradt, D.P.H. Hasselman, and F.F. Lange, Ed., Plenum Press, 1974, p 201–229

R.G. Liptai, D.O. Harris, and C.A. Tatro,Acoustic Emission, STP 505, ASTM, 1972

J.R. Matthews,Acoustic Emission, Gordon & Breach, 1983

T.C. Nerz, J.E. Nerz, B.A. Kushner, A.J. Rotolico, and W.L. Riggs, Evaluation of HEP Sprayed Tungsten Carbide/Cobalt Coating Using Design of Experiment Method,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 405–414

M.M Mayuram and R. Krishnamurphy, Some Studies on Acoustic Emission Application in Assessing Tribological Characteristics of Plasma Sprayed Ceramic Coatings,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, ASM International, 1992,p 711–715

N. Iwamoto, M. Kamai, and G. Ueno, Examination of Tungsten Carbide Coatings for Thermal Cycling Using NDT,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 259–265

H. Nakahira, Y. Harada, N. Mifune, T. Yogoro, and H. Yamane, Advanced Thermal Barrier Coatings Involving Efficient Vertical MicroCracks,Thermal Spray: International Advances in Coatings Technology, C.C. Berndt, Ed., ASM International, 1992, p 519–524

H.L. Dunegan, Quantitative Capabilities of Acoustic Emission for Predicting Structural Failure,Prevention of Structural Failure, American Society for Metals, 1975, p 86–113

T. Tsuru, A. Sagara, and S. Haruyama, Acoustic Emission Measurements to Evaluate the Degradation of Coating Films,Corrosion, Vol 43 (No. 11), 1987, p 703–707

F. Bordeaux, C. Moreau, and R.G. Saint Jacques, Acoustic Emission Study of Failure Mechanisms in TiC Thermal Barrier Coatings,Surf. Coat. Technol, Vol 54/55,1992, p 70–76

C.C. Berndt, Failure Processes Within Ceramic Coatings at High Temperatures,J. Mater. Sci., Vol24,1989,p3511–3520

I.G. Scott,Basic Acoustic Emission, Gordon & Breach, 1991

C.C. Bemdt and R. A. Miller, Failure Analysis of Plasma-Sprayed Thermal Barrier Coatings,Thin Solid Films, Vol 119,1984, p 173–184

C.C. Bemdt, Examination of Coating Failure by Acoustic Emission,Thermal Barrier Coatings Workshop, NASA Lewis Research Center, Cleveland, 21-22 May, 1985, p 127–137

H.-D. Steffens and H.-A. Crostack, Non-Destructive Testing of Thermally Sprayed Coatings,General Aspects of Thermal Spraying, J.H. Zaat, Ed., The Hague, Netherlands, 1980, p 120–128

K. Hoehne, Moeglichkeiten der zerstoerungsfreien Prunfung von Metallspritzschichten,Schweisstechnik, Vol 13,1963, p 55–61

W. Francke and A.W.J. de Gee, A Non-Destructive Method for the Measurement of the Adhesive Bond Strength of Thermally Sprayed Nonfused Coatings,Proc. Int. Conf. Advances in Surface Technology, London, 1978, p 99–109

R.L. Cox, D.P. Almond, and H. Reiter, Ultrasonic Studies of Plasma Sprayed Coatings,General Aspects of Thermal Spraying, J.H. Zaat,Ed., The Hague, Netherlands, 1980, p 133–137

Y. Suga, Harjanto, and J. Takahashi, Study on the Ultrasonic Test for Evaluating the Adhesion of Sprayed Coatings to a Substrate,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 247–252

E. Lugscheider, P. Jokiel, G. Purshe, O. Roman, and K. Yushchenko, Particle Reinforced Material Containing Titanium-I-Boride for Wear Protection,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 647–651

K. Furukubo, S. Oki, and S. Gohda, Relationship Between Wear and Microstructures of Ceramic Spray Coatings,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 705–709

R.C. Hendricks and G. McDonald, “Assessment of Variations in Thermal Cycle Life Date of Thermal Barrier Coated Rods,≓ TM-81743, NASA, Cleveland, 1981

H.-D. Steffens and U. Fischer, Characterization and Thermal Shock Testing of Yttria-Stabilized Zirconia Coatings,Surf. Coat. Technoi, Vol 32,1987, p 327–338

S.J. Grisaffe, “Analysis of Shear Bond Strength of Plasma-Sprayed Alumina Coatings on Stainless Steel,≓ TN D3113, NASA, Cleveland,1965

H. Grützner and H. Weiss, A Novel Shear Test for Plasma-Sprayed Coatings,Surf. Coat. Technol.,Vol45,1991,p317–323

K.K. Schweitzer, M.H. Zeihl, and Ch. Schwaminger, Improved Methods for Testing Bond and Intrinsic Strength and Fatigue of Thermally Sprayed Metallic and Ceramic Coatings,Surf. Coat. Technol., Vol 48, 1991,p103–111

M.J. Filiaggi and R.M. Pilliar, Mechanical Testing of Plasma-Sprayed Ceramic Coatings on Metal Substrates: Interfacial Fracture Toughness and Tensile Bond Strength,J. Mater. Sci., Vol 26,1991, p 5383–5395

H.R. Brown and A.C.M. Yang, The Use of Peel Test to Examine the Self Adhesion of Polyimide Films,J. Adhes. Sci. Technol., Vol 6 (No. 3), 1992, p 333–346

M. Mantel and F. Descaves, Study of a T-Type Peel Test on a Metal/Polymer/Metal Sheet Sandwich,J. Adhes. Sci. Technol., Vol 6 (No.3), 1992, p 357–376

B. Lawn and R. Wilshaw, Review—Indentation Fracture: Principles and Applications,J Mater. Sci., Vol 10,1975, p 1049–1081

H.R. Hertz,Hertz’s Miscellaneous Papers, MacMillian Press, London,1882, chap. 5,6

B.R. Lawn and D.B. Marshall, Indentation Fracture and Strength Degradation in Ceramics,Fracture Mechanics of Ceramics, Vol 3, R.C. Bradt, D.P.H. Hasselman, and F.F. Lange, Ed., Plenum Press, 1978, p 205–229

P. Ostojic and R. McPherson, Indentation Toughness Testing of Plasma Sprayed Coatings,Mater. Forum, Vol 10 (No. 4), 1987, p 247–255

J.G. Binner and R. Stevens, The Measurement of Toughness by Indentation,Trans. J. Br. Ceram. Soc, Vol 83,1984, p 168–172

C. Richard, J. Lu, J.F. Flavenot, G. Beranger, and F. Decomps, Study of Cr2U3 Coating Materials and Characterization by an Interfacial Test of Coating/Substrate Adherence,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 11–16

R. Dal Maschio, V.M. Sgavo, L. Bertamini, and E. Galvanetto, Measurement of Metal-Ceramic Adhesion by Indentation Technique in Thick TBCs,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 947–951

C.C. Bemdt, J. Karthikeyan, R. Ratanaraj, and Yang Da Jun, Material Property Variations in Thermally Sprayed Coatings,Thermal Spray Coatings: Properties, Processes, and Applications, T.F. Bemecki, Ed., ASM International, 1992, p 199–203

C.C. Bemdt, J. Ilavsky, and J. Karthikeyan, Microhardness-Lifetime Correlations for Plasma Sprayed Thermal Barrier Coatings,Thermal Spray: International Advances in Coatings Technology, C.C. Bemdt, Ed., ASM International, 1992, p 941–946

C.K. Lin and C.C. Bemdt, Microhardness Variation in Thermally Sprayed Coatings,Thermal Spray Coatings: Research, Design and Application, C.C. Bemdt and T.F. Bemecki, Ed., ASM International, 1993, p561–568

R.A. Miller, Oxidation-Based Model for Thermal Barrier Coating Life,J. Am. Ceram. Soc., Vol 67 (No. 8), 1984, p 517–521

W. Weibull, A Statistical Theory of the Strength of Materials,Ingeniorsvetenskapakademiens. Handlinger Nr., Vol 151, 1939

S.B. Batdorf, Fundamentals of the Statistical Theory of Fracture,Fracture Mechanics of Ceramics, Vol 3, R.C. Bradt, D.P.H. Hasselman, and F.F. Lange, Ed., Plenum Press, 1978, p 1–30

W. Weibull, A Statistical Distribution Function of Wide Applicability,J. Appl. Mech., Sept 1951,p293–297

K.C. Kapur and L.R. Lamberson,Reliability in Engineering Design, John Wiley & Sons, 1977

D.G.S. Davies, The Statistical Approach to Engineering Design in Ceramics,Proc. Br. Ceram. Soc, 1973, p429–452

B. Bergman, On the Estimation of the Weibull Modulus,J. Mater. Sci. Lett, Vol 3,1984, p 689–692

K. Trustrum and A. DE S. Jayatilaka, On Estimating the Weibull Modulus for a Brittle Material,J. Mater. Sci., Vol 14,1979, p 1080–1084

J.S. White, The Moments of Log-Weibull Order Statistics,Technometrics,Vol.11 (No. 2), 1969, p 373–386

A.C. Cohen, Maximum Likelihood Estimation in the Weibull Distribution Based on Complete and on Censored Samples,Technometrics, Vol 7 (No. 4), 1965, p 579–588

J.F. Lawless, inStatistical Models and Methods for Lifetime Data, John Wiley & Sons, 1982, p 141–202

E.H. Lloyd, Least-Squares Estimation of Location and Scale Parameters Using Order Statistics,Biometrika, Vol 39,1952, p 88–95

M.G. Kendall and A. Stuart,The Advanced Theory of Statistics, Vol 2, 2nd ed., Griffin, London, 1969

N.R. Mann, Table for Obtaining the Best Linear Invariant Estimates of Parameters of the Weibull Distribution,Technometrics, Vol 9,1967, p629–645

N.R. Mann, “Results on Location and Scale Parameter Estimation with Application to the Extreme Value Distribution,≓ ARL 67-0023, Wright-Patterson Air Force Base, 1967

J.W. Heavens and P.N. Murgatroyd, Analysis of Brittle Fracture Stress Statistics,J. Am. Ceram. Soc, Vol 53 (No. 9), 1970, p 503–505

R.A. Fisher, Two New Properties of Mathematical Likelihood,Proc. R. Soc. (London)A.,Vol 144,1934,p285–307

J.F. Lawless, Confidence Interval Estimation for the Weibull and Extreme Value Distributions,Technometrics, Vol 20,1978, p 355–364

NR. Mann, K.W. Fertig, and E.M. Scheuer, “Confidence and Tolerance Bounds and a New Goodness of Fit Test for the Two-Parameter Weibull or Extreme Value Distribution with Tables for Censored Samples of Size 3(1)25,≓ ARL 71-0077, Wright-Patterson Air Force Base, 1971

N.R. Mann and K.W. Fertig, Tables for Obtaining Confidence Bounds and Tolerance Bounds Based on Best Linear Invariant Estimates of Parameters of the Extreme Value Distribution,Technometrics, Vol 15, 1973,p 87–101

L.J. Bain,Statistical Analysis of Reliability and Life-Testing Models, Marcel Dekker, 1978

D.R. Thoman, L.J. Bain, C.E. Antle, Inference on the Parameters of the Weibull Distribution,Technometrics, Vol 11, 1969, p 445–460

R.B. Abernethy, J.E. Breneman, C.H. Medlin, and G.L. Reinman,Weibull Analysis Handbook, AFWAL-TR-83-2079, Propulsion Laboratory, Air Force Wright Aeronautical Laboratories, Wright-Patterson ir Force Base, 1983

G. Taguchi and S. Konishi,Taguchi Methods, Orthogonal Arrays and Linear Groups, American Supplier Institute, 1987

P. Ross,Taguchi Techniques for Quality Engineering, McGraw-Hill, 1988

G.E.P. Box, Signal to Noise Ratios: Performance Criteria and Transformation,Technometrics, Vol 30 (No. 1), 1988, p 1–17

S. Bisgaard, Optimizing Thermal Spray Processes Going Beyond Taguchi Methods,Thermal Spray Research and Application, T.F. Bernecki, Ed., ASM International, 1991, p 661–667

Author information

Authors and Affiliations

Additional information

Based on “Measurement of Adhesion for Thermally Sprayed Material,”Journal of Adhesion Science and Technology.

Rights and permissions

About this article

Cite this article

Lin, C.K., Berndt, C.C. Measurement and analysis of adhesion strength for thermally sprayed coatings. JTST 3, 75–104 (1994). https://doi.org/10.1007/BF02649003

Issue Date:

DOI: https://doi.org/10.1007/BF02649003