Abstract

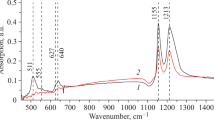

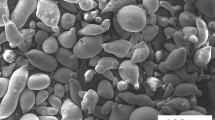

Sprayed coatings are normally impregnated with an epoxy prior to metallographic specimen preparation procedures. The effect of specimen impregnation technique on the structural and microhardness measurements of sprayed coatings has been evaluated. Independent, simultaneous, and controlled evacuation of both the specimen and the resin ensures complete impregnation of pores, yielding metallographic specimens with minimum abrasive loss and minimum scatter in the measured coating properties.

Similar content being viewed by others

References

R.J. Hussey, P.E. Beaubien and D. Caplan, The Metallography of Oxide Scales on Metals,Metallography, Vol 6, 1973, p 27–36.

P.B. Petretsky, Mounting Metallographic Specimens for Edge Retention,Microstntct. Sci., Vol 5, 1977, p 273–276.

L.E. Samuels,Metallographie Polishing by Mechanical Methods, 3rd ed., American Society for Metals, 1982, p 23–36

J. Karthikeyan, K.P. Sreekumar, and V.K. Rohatgi, A Simple Vacuum Impregnation System for Metallographic Specimen Preparation,Trans. Ind. Inst. Met., Vol 42, 1989, p 223–225.

G. A. Blann, The Important Role of Microstructural Evaluation in Each Phase of Thermal Sprayed Coating Applications,Thermal Spray: In-ternational Advances in Coating Technology, C.C. Berndt, Ed., ASM International, 1992, p 959–966.

G.A. Blann, Metallographic Specimen Preparation of Thermally Sprayed Coating for Microstructural Analysis,Microstruct. Sci., Vol 17, 1989, p 139–151.

C.C. Berndt, J. Ilavsky, and J. Karthikeyan, Microhardness—Lifetime Correlations for Plasma Sprayed Thermal Barrier Coatings,Thermal Spray: International Advances in Coating Technology, C.C. Berndt, Ed., ASM International, 1992, p 941–947

P. Ostojic and C.C. Berndt, The Variability in Strength of Thermally Sprayed Coatings,Surf. Coat Technol, Vol 30, 1988, p 43–50.

C.C. Berndt, J. Karthikeyan, R. Ratnaraj, and Yang Da Jun, Material Property Variations in Thermally Sprayed Coatings,Thermal Spray Coatings: Properties, Processes and Applications, T.F. Bernecki, Ed., ASM International, 1992, p 199–204

P. Ostojic, “The Adhesion of Thermally Sprayed Coatings,≓ Ph.D. thesis, Monash University, Clayton, Australia, 1986

C.C. Berndt and H. Herman, Anisotropie Thermal Expansion Effects in Plasma-Sprayed ZrO2-8% Y2O3 Coatings,Ceram. Eng. Sci. Proc., Vol 4 (No. 9–10), 1983, p 792–801.

C.C. Berndt, Failure Process within Ceramic Coatings at High Temperature,J. Mater. Sci., Vol 24, 1989, p 3511–3520.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Karthikeyan, J., Sinha, A.K. & Biswas, A.R. Impregnation of thermally sprayed coatings for microstructural studies. JTST 5, 74–78 (1996). https://doi.org/10.1007/BF02647521

Issue Date:

DOI: https://doi.org/10.1007/BF02647521