Abstract

In this article, we propose a theoretical approach based on the mechanics of porous media that can be used to determine, simply and rigorously (some decoupling assumptions are proposed and defended), the expression for the drying shrinkage of a concrete element subjected to drying. We show that the expression for this drying shrinkage reveals a double nonlinearity with respect to relative humidity, in the form φ1ln(h), where φ1 is the porosity occupied by the liquid phase and h is the relative humidity.

In light of this model, we analyze the two hypotheses, both classical and yet different, that, as an initial approximation, treat drying shrinkage as being proportional to the change of relative humidity, Δh, or to the change of water content, ΔC, in the material.

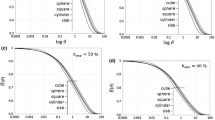

We then establish, within a general framework, the well-known scale effect on the water content versus the size of a test specimen of any shape (i.e. not just cylindrical or spherical). From this result, we can identify the scale effects that follow—both on the weight loss and on the drying shrinkage and drying-related stresses. We show that the expressions proposed to account for these scale effects remain valid for different constitutive laws of concrete, provided that time is a factor only through the diffusion of water in the concrete. This therefore rules out,de facto, all laws of the viscoelastic, viscoplastic types etc., where time appears as such in the expression of the law of mechanical behaviour.

Finally, for three simple constitutive laws—perfectly elastic, brittle elastic, and perfectly plastic—we establish the expression for the drying shrinkage of a drying specimen.

Résumé

Dans cet article, nous proposons une approche théorique, fondée sur la mécanique des milieux poreux, permettant de retrouver, d'une manière simple et rigoureuse (certaines hypothèses de découplages sont proposées et argumentées) l'expression du retrait de séchage d'un élément de béton soumis à la dessiccation. Nous montrons que l'expression de ce retrait de dessiccation fait apparaître une double non linéarité en fonction de l'humidité relative de la forme φ1ln(h) où φ1 est la porosité volumique de la phase liquide eth l'humidité relative.

À la lumière de cette modélisation, nous analysons les deux hypothèses classiques et néanmoins différentes, qui considèrent, en première approximation, que le retrait de dessiccation est proportionnel à la variation d'humidité relative, Δh, ou à la variation de teneur en eau, ΔC, au sein du matériau.

Puis, nous établissons, dans un cadre général, l'effet d'échelle, bien connu, sur la teneur en eau en fonction de la taille de l'éprouvette séchante, et ce pour un corps d'épreuve de forme quelconque (i.e. non plus seulement cylindrique ou sphérique). À partir de ce résultat, nous établissons les effets d'échelle qui en découlent, sur la perte en poids d'une part, et sur le retrait de dessiccation et les contraintes liées au séchage d'autre part. Nous montrons que les expressions proposées pour la prise en compte de ces effets d'échelle restent valables pour différentes lois de comportement du béton, à condition que le facteur temps n'y intervienne que par le biais de la diffusion de l'humidité dans le béton. Ceci exclut donc, de fait, toutes les lois du type viscoélastique, viscoplastique etc. où le temps intervient directement dans l'expression de la loid de comportement mécanique.

Enfin, pour trois lois de comportement simples, élastique parfait, élastique fragile et parfaitement plastique, nous établissons l'expression du retrait de dessiccation d'une éprouvette séchante.

Similar content being viewed by others

Abbreviations

- t, T:

-

Time

- \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{x} ,\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{X} \) :

-

Space variable

- Ω, δΩ:

-

volume element and its surface area

- θ:

-

Temperature

- S:

-

Surface area of the specimen

- p:

-

Pressure

- Pc :

-

Capillary pressure

- pvs(θ):

-

Saturation vapour pressure

- C:

-

Water content in kg/m3

- ρ:

-

Density

- h:

-

Relative humidity

- C=g(h):

-

Isothermal desorption curve relating C and h

- g im :

-

Specific free enthalpy of constituent i

- \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\sigma } } \) :

-

Stress tensor

- σt :

-

Tensile strength of the concrete

- \(\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\underset{\raise0.3em\hbox{$\smash{\scriptscriptstyle-}$}}{\varepsilon } } \) :

-

Strain tensor

- ϕ:

-

Porosity

- E:

-

Young's modulus

- J(t,τ):

-

Creep function of the concrete

- R(t,τ):

-

Relaxation function of the concrete

- δ, d, D:

-

Coefficients of diffusion

- superscript l:

-

For the liquid phase

- superscripts s:

-

For the solid phase

- superscript g:

-

For the gaseous phase, “g=v+a”

- superscript v:

-

For water vapour

- superscript a:

-

For air

- index 0:

-

For the reference condition

References

Abdunur, C., ‘Mesures directes des contraintes sur la pile no 5 du Viaduc du Charmaix’, Internal report LCPC (1986).

Abiar, G., ‘Contribution à l'étude des déformations différées du béton en tenant compte de l'hygrométrie interne: un modèle de séchage pour le béton’, Doctoral Thesis of ENPC (1986).

Acker, P., ‘Comportement mécanique du béton: apports de l'approche physico-chimique’, Rapport de recherche LPC no 152 (1988).

Acker, P., ‘Retraits et fissurations du béton’, Documents scientifiques et techniques AFPC, ISSN no 0150-6900 (1993).

Baroghel-Bouny, V., ‘Caractérisation microstructurale et hydrique des pâtes de ciment et bétons ordinaire et à hautes performances’, Doctoral Thesis of ENPC (1994).

Bazant, Z.P. and Najjar, L.J., ‘Nonlinear water diffusion in nonsaturated concrete,’Mater. Struct. 5 (1972) 3–20.

Bazant, Z.P., Sener, S. and Kim, J.K., ‘Effect of cracking on drying permeability and diffusivity of concrete,’ACI Materials Journal 84-M35 (1986) 351–357.

Bazant, Z.P. and Chern, J.C., ‘Stress-induced thermal and shrinkage strains in concrete,’J. of Engng. Mech 113 (10) (1987) 1493–1511.

Bazant, Z.P. and Kim, J.K., ‘Consequences of diffusion theory for shrinkage of concrete,’Mater. Struct. 24 (1991) 323–326.

Bazant, Z.P., ‘Current status and advances in the theory of creep and interaction with fracture’, Proc. of the Fourth Int. Rilem Symp. on Creep and Shinkage of Concrete, Barcelona, Edited by Z.P. Bazant and I. Carol (E & FN Spon, 1993).

Bazant, Z.P. and Xi, Y., ‘Drying creep of concrete: constitutive model and new experiments separating its mechanisms,’Mater. Struct. 27 (1994) 3–14.

ConCreep 4, ‘Creep and shrinkage of concrete: Mathematical modeling’, Proc. of the Fourth Rilem Int. Symposium, Z.P. Bazant, Editor, Evanston, USA, 1986.

Coussy, O., ‘Mechanics of Porous Continua’ (J. Willey & Sons).

Elouard, A. and Ulm, F.-J., ‘TEXO/HEXO-PROB, notice d'utilisation’, Document CESAR-LCPC, 1994.

Granger, L., ‘Comportement différé du béton dans les enceintes de centrales nucléaires: Analyse et modélisation’, Doctoral Thesis of ENPC, 1994.

Hua, C., ‘Analyse et modélisation du retrait d'autodessiccation de la pâte de ciment durcissante’, Doctoral Thesis of ENPC, 1992.

Lassabatère, T., ‘Approche thermo-poro-hydromécanique en milieu poreux non saturé, application au retrait de dessication du béton’, Doctoral Thesis of ENPC, 1994.

Mensi, R., Acker, P., and Attolou, A., ‘Sechage du béton: analyse et modélisation,’Mater. Struct. 21 (1988) 3–10.

Pihlajavaara, S.E., ‘Estimation of drying of concrete at different relative humidities and temperatures of ambient air with special discussion about fundamental features of drying and shrinkage,’ in Creep and Shrinkage in Concrete Structures,” Edited by Z.P. Bazant and F.H. Wittmann, (J. Wiley & Sons, New-York, 1982).

Rossi, P. and Boulay, C., ‘Influence of free water in concrete on the cracking process,’Magazine of Concrete Research 152 (September 1990) 143–146.

Rossi, P., Wu, X., Le Maou, F. and Belloc, A., ‘Effet d'échelle sur le comportement du béton en traction,’Bull. Labo. P. et C. 182 (1993a) 11–20.

Rossi, P. and Wu, X., ‘A probabilistic model for material behaviour analysis and appraisal of the structure of concrete’, Proc. of the 1st Bolomey workshop on numerical models in fracture mechanics of concrete, F.H. Wittmann Editor, Zürich, July 1992, Balkema.

Rossi, P. Ulm, F.J. and Hachi, F., ‘Compressive behaviour of concrete: physical mechanisms and modelling’, Proposed for publication by ASCE, 1994.

Sicard, V., François, R., Ringot, E. and Pons, G., ‘Influence of creep and shrinkage on cracking in high-strength concrete,’Cement and Concrete Research 22 (1992) 159–168.

Toutlemonde, F. and Granger, L., ‘Maîtriser la rupture du béton: améliorations du matériau, progrès de la modélisation, exemples industriels,’Revue de métalurgie et cahiers d'information techniques, série Sc. et génie des matériaux92 (1995) 285–301.

Verbeck, G.J. and Helmuth, R.H., ‘Structures and physical properties of cement paste’, Proc. 5th Int. Symp. on the Chemistry of Cement, Tokyo, Japan, 1968.

Wittmann, F.H., ‘On the influence of stress on shrinkage of concrete’, Proc. of the Fourth Int. Rilem Symp. on Creep and Shinkage of Concrete, Barcelona, Edited by Z.P. Bazant and I. Carol (E & FN Spon, 1993) 151–157.

Wittmann, F.H., ‘Creep and shrinkage mechanisms,’ in ‘Creep and Shrinkage in Concrete Structures,’ Edited by Z.P. Bazant and F.H. Wittmann (J. Wiley & Sons, New-York, 1982).

Author information

Authors and Affiliations

Additional information

Editorial note Dr. L. Granger is a RILEM Affiliate Member. He is active in Technical Committee 160-MLN on Methodology for Life prediction of concrete structures in Nuclear power plants. Dr. J.-M. Torrenti works at the CEA, which is a RILEM Titular Member. Dr, P. Acker is a RILEM Senior Member. He is active in Technical Committee 107-CSP on Creep and Shrinkage Prediction models and 119-TCE on Avoidance of Thermal Cracking at Early ages. He is a member of the Editorial Group of TC 090-FMA on Fracture Mechanics of concrete-Applications, and a Corresponding Member of TCs 114-CCS on Computer programmes for Creep and Shrinkage prediction models and 123-MME on Use of Microstructural Models and Experst systems for cementitious materials.

Rights and permissions

About this article

Cite this article

Granger, L., Torrenti, J.M. & Acker, P. Thoughts about drying shrinkage: Scale effects and modelling. Mat. Struct. 30, 96–105 (1997). https://doi.org/10.1007/BF02486310

Issue Date:

DOI: https://doi.org/10.1007/BF02486310