Abstract

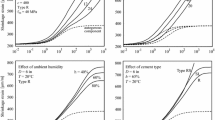

The source of shrinkage and drying creep is the drying process. From the diffusion analysis of drying one can estimate the shrinkage strain. Same as drying, the shrinkage times scale as the square of the effective specimen thickness (or size), D, commonly characterized by the volume-surface ratio. But there is also an additional effect of cross section shape. In the creep and shrinkage prediction model B4 (a new Draft RILEM Recommendation, Mater Struct 48:753–750, 2015), the shape effect is taken into account by shape factor \(k_{\rm{s}}\) multiplying D. However, because of the strong nonlinearity of the diffusion equation for drying, the optimal \(k_{\rm{s}}\) values depend also on the environmental humidity. In model B4, as well as its predecessors since 1975, the \(k_{\rm{s}}\) values have been specified for typical shapes, i.e. the slab, cylinder, prism, sphere and cube, with values calculated approximately for only one relative humidity—65 %. Here the \(k_{\rm{s}}\) values for the same typical shapes are calculated with greater accuracy and for different environmental humidities—30, 40, 50, 60, 70 and 80 %, which allows interpolation in between. The \(k_{\rm{s}}\) values for the typical shapes range from 1.00 to 1.41.

Similar content being viewed by others

References

Technical Committee RILEM, TC-242-MDC (Z.P. Bažant, chair), (2015) Model B4 for creep, drying shrinkage and autogenous shrinkage of normal and high-strength concretes with multi-decade applicability. (RILEM draft recommendation: TC-242-MDC multidecade creep and shrinkage of concrete: material model and structural analysis). Mater Struct 48:753–750

Hubler MH, Wendner R, Bažant ZP (2015) Statistical justification of model B4 for drying and autogenous shrinkage of concrete and comparisons to other models. Mater Struct 48:797–814

Wendner R, Hubler MH, Bažant ZP (2015) Statistical justification of model B4 for multi-decade concrete creep using laboratory and bridge databases and comparisons to other models. Mater Struct 48:815–833

Bažant ZP, Najjar LJ (1972) Nonlinear water diffusion in nonsaturated concrete. Mater Struct (RILEM, Paris) 5:3–20

Bažant ZP, Osman E, Thonguthai W (1976) Practical formulation of shrinkage and creep in concrete. Mater Struct RILEM 9:395–406

Bažant ZP, Baweja S (1995) Justification and refinement of Model B3 for concrete creep and shrinkage. 2. Updating and theoretical basis. Mater Struct (RILEM, Paris) 28:488–495

Bažant ZP, Baweja S (2000) Creep and shrinkage prediction model for analysis and design of concrete structures: Model B3. In: Al-Manaseer A (ed.) Adam Neville symposium: creep and shrinkage-structural design effects, ACI SP-194. American Concrete Institute, Farmington Hills, Michigan, pp 1–83 (minor update of [6])

Bažant ZP, Donmez A (2015) Extrapolation of short-time drying shrinkage tests based on measured diffusion size effect: concept and reality. Mater Struct (RILEM) 49(1):411–420

Abrams MS, Gustaferro AH (1968) Fire endurance of concrete slabs as influenced by thickness, aggregate type, and moisture. J Portland Cem Assoc Res Dev Lab 10(2):9–24 (PCA Bulletin 223)

Abrams MS, Monfore GE (1965) Application of a small probe-type relative humidity gage to research on fire resistance of concrete. J Portland Cem Assoc Res Dev Lab 7(3):2–12 (PCA Bulletin 186)

Abrams MS, Orals DL (1965) Concrete drying methods and their effect on fire resistance, in: Moisture of materials in relation to fire tests. STP No. 385:52–73, publ. by American Society for Testing Materials (PCA Bulletin 181)

Hancox NL (1967) A note on the form of the rate of drying curve for cement paste and its use in analyzing the drying behavior of this material. RILEM Bull 36:197–201

Hanson JA (1968) Effects of curing and drying environments on splitting tensile strength. Am Concr Inst J 65:535–543 (PC A Bulletin D141)

Helmuth RA, Turk DH (1967) The reversible and irreversible drying shrinkage of hardened portland cement and tricalcium silicate paste. J Portland Cem Assoc Res Dev Lab 9(2):8–21 (PCA Bulletin 215)

Hughes BP, Lowe IRG, Walker J (1966) The diffusion of water in concrete at temperatures between 50 and 95 \(^{\circ }\) C. Br J Appl Phys 17:1545–1552

Acknowledgments

Partial financial support has been obtained under grant CMMI-1129449 of the U.S. National Science Foundation. The first author thanks The Scientific and Technological Research Council of Turkey for financially supporting his pre-doctoral fellowship at Northwestern University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dönmez, A., Bažant, Z.P. Shape factors for concrete shrinkage and drying creep in model B4 refined by nonlinear diffusion analysis. Mater Struct 49, 4779–4784 (2016). https://doi.org/10.1617/s11527-016-0824-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1617/s11527-016-0824-6