Abstract

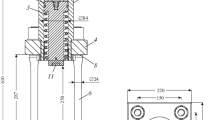

A numerical method for optimizing the structure of a high-pressure unit with diamond anvils as pressure is created in the vessel is developed and realized in the form of a set of programs. The method includes the following: determination of the stress — strain state of the anvils and the deformable intervening layer of material; evaluation of the strength of the anvils;the development of a mathematical model to describe the dependence of the strength of the anvils on the parameters being optimized; determination of the optimum points of the model. A combination of optimum parameters is obtained, making it possible to reach a design pressure of 465 GPa. This pressure is 2.5 times higher than the pressure recorded in anvils with a similar pressure distribution (N. K. Mao and P. M. Bell, 1978).

Similar content being viewed by others

Literature cited

A. Jayaraman, “Ultrahigh pressure,” Rev. Sci. Instrum.,57, No. 6, 1013–1031 (1986).

F. P. Bundy, “Design and development of apparatus to achieve the highest possible static pressures,” Physica,139, No. 140B, 42–51 (1986).

D. M. Adams and A. C. Shaw, “A computer-aided design study of the behavior of diamond anvil under stress,” J. Phys. D: Appl. Phys.,15, No. 6, 1609–1635 (1982).

M. S. Bruno and K. J. Dunn, “Stress analysis of a beveled diamond anvil,” Rev. Sci. Instrum.,55, No. 6, 940–943 (1984).

M. V. Astrakhan', B. I. Beresnev, and V. G. Synkov, “Design of diamond anvils,” Sverkhtverdye Mater., No. 3, 16–20 (1986).

A. L. Ruoff, H. Xia, H. Luo, and Y. K. Vohra, “Miniaturization techniques for obtaining static pressures comparable to that at the center of the Earth: x-ray diffraction at 416 GPa,” Rev. Sci. Instrum.,61, 9830 (1990).

A. L. Ruoff and H. Luo, Stresses and Strains in Diamond Anvils in the Multimegabar Range. To be published.

W. C. Moss and K. Goettel, “Finite element design of diamond anvils,” Appl. Phys. Lett.,50, No. 1, 25–27 (1987).

H. K. Mao and P. M. Bell, “High-pressure: Sustained static generation of 1.36 to 1.72 Mbar,” Science,200, No. 4346, 1145–1147(1978).

E. P. Unksov, Engineering Theory of Plasticity [in Russian], Mashgiz, Moscow (1959).

V. I. Levitas, Large Elastoplastic Strains of Materials at High Pressure [in Russian], Naukova Dumka, Kiev (1987).

V. V. Sokolovskii, Theory of Plasticity [in Russian], Vysshaya Shkola, Moscow (1969).

A. D. Platonov, “Optimization of finite-element methods for calculating parameters of linear fracture mechanics (K1 K2, J),” Author's Abstract of Engineering Sciences Candidate Dissertation. Kiev (1984).

N. V. Novikov, V. I. Levitas, R. A. Zolotarev, et al., “Testing of sets of programs developed to solve problems of thermomechanics,” Dopov. Akad. Nauk Ukr. RSR, No. 4, 30–33 (1985).

J. E. Field, The Properties of Diamond, Academic Press, London, New York-San Francisco (1979).

S. G. Lekhnitskii, Theory of Elasticity of Anisotropic Bodies [in Russian], Nauka, Moscow (1977).

V. I. Levitas, “Construction of a theory of ideal plasticity,” Probl. Prochn., No. 11, 56–62 (1980).

V. I. Levitas, “Certain models of the inelastic deformation of materials. Reports Nos. 1–2,” ibid., No. 12, 70–83 (1980).

G. A. Voronin, V. I. Mal'nev, and G. F. Nevstruev, “Effect of inclusions on the strength of synthetic diamonds at high pressures,” Sverkhtverdye Mater., No. 2, 33–37 (1984).

G. Libovitz (ed.), Fracture: Mathematical Principles of the Theory of Fracture [Russian translation], Mir, Moscow (1975), Vol. 2.

W. D. Harlans, “Energy relations of surface of solids,” J. Chem. Phys.,10, No. 5, 268 (1942).

S. B. Polotnyak, “Stress-strain state and limiting state of diamond anvils in a high-pressure apparatus during loading and unloading,” in: Ultrahard Materials in the National Economy [in Russian], In-t Sverkhtverdykh Materialov, Kiev (1989), pp. 16–19.

F. S. Novik and Ya. B. Arsov, Use of Factorial Experiments to Optimize Metallurgical Processes [in Russian], Mashinostroenie, Moscow; Tekhnika, Sofia.

L. P. Ruzinov and R. I. Slobodchikova, Experiment Planning in Chemistry and Chemical Engineering [in Russian], Khimiya, Moscow (1980).

M. M. Potemkin, “Use of computers to study processes in the corrosion protection of metals,” Materials of the Second All-Republic Scientific—Technical Conference on the Corrosion and Corrosion-Protection of Metals. “Development and Use of Anti-Corrosive Metallic Coatings,” Summary of Documents, Dnepropetrovsk (1981), pp. 202–203.

J. A. Xu, H. K. Mao, and P. M. Bell, “High-pressure ruby and diamond fluorescence observation at 0.21 to 0.55 terapascal,” Science,232, No. 4756 (1986), pp. 1404–1406.

Author information

Authors and Affiliations

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 64–74, April, 1994.

Rights and permissions

About this article

Cite this article

Novikov, N.V., Levitas, V.I., Polotnyak, S.B. et al. Numerical method for optimizing the design of a high-pressure apparatus with diamond anvils. Strength Mater 26, 294–302 (1994). https://doi.org/10.1007/BF02207410

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02207410