Abstract

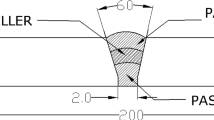

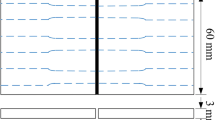

This work outlines the experimental validation of a numerical method which determines the size of the heat affected zone (HAZ) in a low carbon steel plate using the gas metal arc welding technique. The welding parameters match between the experimental and numerical simulations. The later allows the calculation of the weld beads and temperature fields from which the size of the HAZ can be inferred. This size from numerical simulations compares quite well with the experimentally measured HAZ from the metal grain macrostructure. A relationship between the bead size and the thermal energy source parameters, defined by the Goldak’s double ellipsoid, is found. Finally, the size of the HAZ is optimized by Taguchi’s method, which make use of the signal-to-noise ratio and the analysis of variance to obtain the influence of the parameters on the size of HAZ. The numerical code can be used for other electric arc welding techniques as GTAW or FCAW.

Similar content being viewed by others

Abbreviations

- ah, ch :

-

Ellipsoidal semi-axes (mm)

- B:

-

Width of the low carbon steel to be simulated (m)

- Cp :

-

Caloric capacity (J kg−1 K−1)

- D:

-

Thickness of the low carbon steel plate to be simulated (m)

- K:

-

Fourier conductivity (J m−1 s−1 K−1)

- L:

-

Length of the low carbon steel plate to be simulated (m)

- n:

-

Number of trials

- P:

-

Power of the electric arc (W)

- p value:

-

Is the probability of obtaining a test statistic result

- To :

-

Initial temperature (ºC)

- Tf :

-

Fusion temperature (ºC)

- ua, uc :

-

Ellipsoidal non dimension heat source parameters

- v s :

-

Welding speed (m/s)

- Yij :

-

The measured value of quality characteristics

- α:

-

Thermal diffusivity (m2/s)

- ΔH:

-

Phase change enthalpy (J kg−1)

- Δx:

-

Longitudinal direction to the movement (m)

- Δy:

-

Perpendicular direction to the movement (m)

- ρ:

-

Density (kg m−3)

- ANOVA:

-

Variance analysis

- EBW:

-

Electron beam welding

- FCAW:

-

Flux cored arc welding

- FSW:

-

Friction stir welding

- GMAW:

-

Gas metal arc welding

- GTAW:

-

Gas tungsten arc welding

- HAZ:

-

Heat affected zone

- Nd-Yag:

-

Neodymium-doped yttrium aluminium garnet

- SAW:

-

Submerged arc welding

- SMAW:

-

Shield metal arc welding

- S/N:

-

Signal to noise ratio

- TIG:

-

Tungsten inert gas

- i, j :

-

Subscripts of finite differences equations

- i th , j th :

-

Trials

References

Boumerzoug Z, Raouache E, and Delaunois F, Mater Sci Eng 0 (2011) 530.

Wang Y, Wang L, Di X, Shi Y, Bao X, and Gao X, Comput Mater Sci 0 (2013) 68.

Kumar R, Tewari V K, and Prakash S, J Alloys Compd 1–2 (2009) 479.

Zhang Z Z, and Wu C S, Comput Mater Sci 0 (2012) 65.

Zhang M, Nie Y, Wang Q, and Chen H, Guangzhou (2013), p 415.

Hamad F, Collins L, and Volkers R, in Proceedings of the Symposium 7th International Pipeline Conference, American Society of Mechanical Engineers, Calgary (2009), p 553.

Gunaraj V, and Murugan N, Weld J 1 (2002) 81.

Cho M H, Lim Y C, and Farson D F, Weld J 12 (2006) 85.

Li M-Y, and Kannatey-Asibu J-E, Weld J 3 (2002) 81.

Okui N, Ketron D, Bordelon F, Hirata Y, and G. Clark, Weld J 2 (2007) 86.

Murugan N, and Parmar R S, J Mater Process Technol 4 (1994) 41.

Raveendra J, and Parmaris R, Met Constr 1 (1987) 19.

Koleva E, Vacuum 2 (2001) 62.

Gunaraj V, and Murugan N, Weld J N.Y. 3 (2002) 81.

Ranjbarnodeh E, Weis S, Hanke S, and Fischer A, J Min Met Sect B 1 (2012) 48.

Vitek J, Iskander Y, Oblow E, Babu S, David S, Fuerschbach P, Smartt H, and Pace D, Neural Network Modeling of Pulsed-Laser Weld Pool Shapes in Aluminum Alloy Welds, Report ORNL/CP–98605, Oak Ridge National Lab., Oak Ridge, (1998).

Uzun H, Donne C D, Argagnotto A, Ghidini T, and Gambaro C, Mater Des 1 (2005) 26.

Benyounis K Y, and Olabi A G, Adv Eng Softw 6 (2008) 39.

Roy R K, Design of Experiments Using the Taguchi Approach: 16 Steps to Product and Process Improvement, Wiley Interscience, Hoboken (2001).

Meseguer-Valdenebro J L, Martínez-Conesa E J, Eguía V M, and Paya M V, Therm Sci 11 (2014)18.

Allen T T, Richardson R W, Tagliabue D P, and Maul G P, Weld J 5 (2002) 81.

Vrouwenvelder T, Leira B J, and Sykora M, Struct Eng Int 1 (2012) 22.

Suarez J C, Carrillo E, and Molleda F, Rev Sold 2 (1991) 21.

Eagar T W, and Tsai N -S, Weld J 12 (1983) 62.

Christensen N, de Davies V, and Gjermundsen K, Br Weld J 2 (1965) 12.

CEN Technical Committee, Eurocode 3: Design of Steel Structures. Part 1-2. General Rules-Structural Fire Design (1995).

DuPont J, and Marder A, Weld J Weld Res Suppl 12 (1995) 74.

Cho M H, Lim Y C, and Farson D F, Weld J 12 (2006) 85.

Nguyen N T, Mai Y W, Simpson S, and Ohta A, Weld J 3 (2004) 83.

Fachinotti V D, Amilcar Anca A, and Cardona A, Int J Numer Methods Biomed Eng 4 (2011) 27.

Goldak J, Chakravarti A, and Bibby M, Met Trans B 2 (1984) 15.

Estrems Amestoy M, Miguel-Eguía V, and Martínez-Conesa E J, Dyna 9 (2009) 84.

Kim Y S, and Eagar T W, Weld J 4 (1993) 72.

Pawłowski B, J Achiev Mater Manuf Eng 2 (2011) 49.

Chipman J, Met Trans 1 (1972) 3.

Haragopal G, Reddy P V R R, Reddy G C M, and Subrahmanyam J V, J Sci Ind Res 10 (2011) 70.

Bozkurt Y, Mater Des 0 (2012) 35.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meseguer-Valdenebro, J.L., Serna, J., Portoles, A. et al. Experimental Validation of a Numerical Method that Predicts the Size of the Heat Affected Zone. Optimization of the Welding Parameters by the Taguchi’s Method. Trans Indian Inst Met 69, 783–791 (2016). https://doi.org/10.1007/s12666-015-0554-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12666-015-0554-4