Abstract

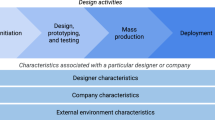

Rapid and successful introduction of new products is a potentially significant source of competitive advantage for manufacturing firms. Organizations need to identify and manage those critical elements of the product development process (PDP) that have a positive influence on new product success. This research identifies the distinctive product development and design practices, policies and tools currently followed by companies (Navy contractors) that participated in an empirical research study known as the Best Manufacturing Practices Program. A summary of practices reported in the case studies is compiled using content analysis techniques, and the most interesting practices by individual companies are highlighted. We find numerous examples of sophisticated CAD techniques being used to enhance the development process, including expert system design advisers, computer simulation, and design databases. Companies are emphasizing the design policies of concurrent engineering and teamwork, and documenting design process knowledge into design manuals. Company effort still appear focused primarily on the phase of detailed design rather than the concept selection phase.

Similar content being viewed by others

References

ANSI/ASQC (1987), American National Standard Q91-1987: Quality Systems — Model for Quality Assurance in Design/Development, Production, Installation, and Servicing, Washington, DC: American National Standards Institution.

BMP: Best Manufacturing Practices, Office of the Assistant Secretary of the Navy (Shipbuilding and Logistics), Washington, DC.

Bebb, B. (1989) Quality Design Engineering: The Missing Link in US Competitiveness, keynote address to the 1989 National Science Foundation Engineering Design Conference, Amherst, MA, June 1989.

Boothroyd, G.; Poli, L.; Munch, L.E.Automatic Assembly, Marcel Dekker, New York, 1982.

Booz, Allen and Hamilton (1082),New Product Management for the 1980s, Allen & Hamilton, New York, 1982.

Commission on Engineering and Technical Systems, National Research Council, 1991.

Cooper, R.G. Why New Industrial Products Fail,Industrial Marketing Management, Vol. 20, 1975, pp. 19–30.

Cooper, R.G. Identifying Industrial New Product Success: Project NewProd,Industrial Marketing Management, Vol. 8, 1979a, pp. 124–135.

Cooper, R.G. The Dimensions of Industrial New Product Success and Failure,Journal of Marketing, Vol. 43, No. 3, 1979b, pp. 93–103.

Cooper, R.G. New Product Success in Industrial Firms,Industrial Marketing Management, Vol. 11, 1982, pp. 215–223.

Cooper, R.G. A Process Model for Industrial New Product Development,IEEE Transactions on Engineering Management, Vol. EM-30, No. 1, 1983, pp. 2–11.

Cooper, R.G; Kleinschmidt, E.J. An Investigation into the New Product Process: Steps, Deficiencies and Impact,Journal of Product Innovation Management, Vol. 3, June, 1986, pp. 71–85.

Cooper, R.G.; Kleinschmidt, E.J. New Products: What Separates Winners from Losers?,Journal of Product Innovation Management, Vol. 4, 1987, pp. 69–184.

Crawford, C.M. Defining the Charter for Product Innovation,Sloan Management Review, Fall 1980, 1980, pp. 3–12.

Crosby, Philip,Quality is Free, McGraw-Hill, New York, 1979.

Dixon, J.; Duffey, M. The Neglect of Engineering Design,California Management Review, Vol. 32, No. 2, 1990, pp. 9–23.

Globe, S.; Levy, G.W.; Schwartz, C.M. Key Factors and Events in the Innovation Process,Research Management, Vol. 16, 1973, pp. 8–15.

Gold, Bela, Approaches to Accelerating Product and Process Development,Journal of Product Innovation Management, Vol. 4, 1987, pp. 81–88.

Hayes, R.; Wheelwright, S.; Clark, K.Dynamic Manufacturing: Creating the Learning Organization, The Free Press, New York, 1988.

Hise, R.; O'Neal, L.; McNeal, J.; Parasuraman, A. The Effect of Product Design Activities on Commercial Success Levels of New Industrial Products,Journal of Product Innovation Management, Vol. 6, 1989, pp. 43–50.

Holsti, O.R.Content Analysis for the Social Sciences and Humanities, Addison-Wesley, Reading, MA, 1969.

Johen, A.; Snelson, Patricia, Success Factors in Product Innovations: A Selective Review of the Literature,Journal of Product Innovation Management, Vol. 6, 1989, pp. 114–128.

Maidique, M.A., Entrepreneurs, Champions and Technological Innovation,Sloan Management Review, Vol. 21, Winter, 1980, pp. 59–76.

Maidique, M.A.; Zirger, B.J. A Study of Success and Failure in Product Innovation: The Case of the US Electronics Industry,IEEE Transactions on Engineering Management, Vol. EM-31, No. November, 1984, pp. 192–203.

Mizuno, Shigeru,Management for Quality Improvement: The Seven New OC Tools, Productivity Press, Cambridge, MA, 1988.

Pahl, G.; Beitz, W.Engineering Design, Springer-Verlag, New York, 1984.

Pugh, S.Total Design, Addison-Wesley, Reading, Mass., 1991.

Stalk, G.; Hout, T.Competing Against Time, Macmillan, New York, 1990.

Verhage, B.: Waalewijn, P.H.; Van Weele, A.J. New Product Development in Dutch Companies: The Idea Generation Stage,European Journal of Marketing, Vol. 15, 1981, pp. 73–85.

Willoughby, W.J. Solving the Risk Equation in Transitioning from Development to Production, DoD 4245.7-M, Washington, D.C.: U.S. Department of Defense, 1983.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Stevenson, S., Dooley, K.J. & Anderson, J.C. The use of best design practices: An analysis of US navy contractors. Research in Engineering Design 6, 14–24 (1994). https://doi.org/10.1007/BF01588088

Issue Date:

DOI: https://doi.org/10.1007/BF01588088