Abstract

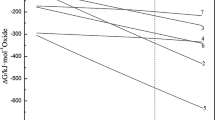

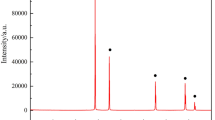

The mechanism of the reduction of carbon/alumina powder mixture in a flowing nitrogen stream was studied. Five steps were found to be involved in the overall reaction.

The consumption rates of Al2O3 and carbon, and the production rate of AIN, were determined to be

in the temperature range 1648–1825 K.

Similar content being viewed by others

References

N. Kuramoto andH. Taniguchi, US Pat. 4618 592 (1986).

H. L. Wang, MS thesis, Department of Mineral Metallurgy and Materials Science, National Cheng Kung University, Tainan, Taiwan (1988).

S. Hirai, T. Miwa, M. Ozawa andH. G. Katayama,J. Jpn Inst. Metals 53 (1989) 1035.

H. Inoue, A. Tsung andM. Kasori,J. Mater. Sci. 25 (1990) 2359.

C. I. Lin andC. Lee, Technical Report to National Science Council of Taiwan, NSC81-0402-E011-02, Taipei, Taiwan (1992).

A. G. Vodopsanov, A. V. Serebryakova andG. N. Kozhevnikov,Izv. Akad. Nauk SSSR Met. 1 (January–February) (1982) 43.

T. Sakai andM. Iwata,J. Ceram. Soc. Jpn 82 (3) (1974) 41.

Y. W. Cho andT. A. Charles,Mater. Sci. Technol. 7 (1991) 495.

L. Brewer,J. Am. Chem. Soc. 73 (1951) 5308.

Y. K. Rao andB. P. Jalan,Metall. Trans. 3 (1972) 2465.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, H.K., Lin, C.I. Mechanism of the reduction of carbon/alumina powder mixture in a flowing nitrogen stream. J Mater Sci 29, 1352–1357 (1994). https://doi.org/10.1007/BF00975088

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00975088