Abstract

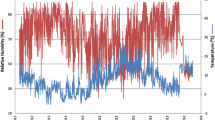

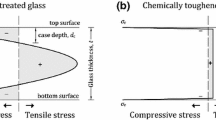

Injection-moulded bars made from poly(methyl methacrylate) (PMMA) polystyrene (PS), polycarbonate (PC) and poly(vinyl chloride) (PVC), have been weathered outdoors in Jeddah, Saudi Arabia, for varying periods. The residual stresses in the bars have been found to vary considerably with exposure and in some cases the surface stress has reversed, becoming tensile. With PS and PVC, significant surface damage developed on exposure and the presence of surface flaws together with tensile residual stresses at the surface can be expected to reduce the resistance to fracture, especially in the case of PS which suffers considerable molecular weight reduction near the surface. The changes in residual stress in PMMA and PC were smaller, and the surface deterioration, examined by scanning electron microscopy, was much less than with PS and PVC. The performance of PMMA and PC in fracture tests generally declined less with weathering than did that of PS and PVC but the materials used were all commercial grades designed for use in Europe and the results obtained here should not be taken to indicate the relative weatherability of the different polymers. The significance of the results relate to the mechanism of failure involving the interaction of reversed residual stresses and surface flaws.

Similar content being viewed by others

References

A. Davis andD. Sims, “Weathering of Polymers” (Applied Science, Barking, 1983).

M. M. Qayyum andA. Davis,Polymer Degrad. Stab. 6 (1984) 201.

L. D. Carpenter, MSc thesis, University of Newcastle upon Tyne (1979).

B. Haworth, MSc thesis, University of Newcastle upon Tyne (1979).

L. D. Coxon andJ. R. White,Polymer Eng. Sci. 20 (1980) 230.

M. M. Qayyum andJ. R. White,Polymer 23 (1982) 129.

Idem, J. Polymer Sci. Polymer Lett. Ed. 21 (1983) 31.

Idem, J. Appl. Polymer Sci. 28 (1983) 2033.

R. G. Treuting andW. T. Read Jr,J. Appl. Phys. 22 (1951) 130.

P. So andL. J. Broutman,Polymer Eng. Sci. 16 (1976) 785.

B. Haworth, C. S. Hindle, G. J. Sandilands andJ. R. White,Plast. Rubb. Proc. Applic. 2 (1982) 59.

J. R. White,Polymer Testing 4 (1984) 165.

R. P. Kusy, H. B. Lee andD. T. Turner,J. Mater. Sci. 11 (1976) 118.

H. Janeschitz-Kriegl,Rhelol. Acta 16 (1977) 327.

M. R. Kamal andV. Tan,Polymer Eng. Sci. 19 (1979) 558.

C. S. Hindle, A. V. Iacopi, C. K. Lam, M. J. Richardson andJ. R. White, unpublished results, 1980–1984.

J. G. Williams,Polymer Eng. Sci. 17 (1977) 144.

G. J. Sandilands andJ. R. White,Polymer 21 (1980) 338.

F. Paredes andP. Frias,J. Mater. Sci. Lett. 1 (1982) 394.

R. J. Bird, J. Mann, G. Pogany andG. Rooney,Polymer 7 (1966) 307.

J. R. White andT. W. Teh,ibid. 20 (1979) 764.

C. J. Singleton, T. Stephenson, J. Isner, P. H. Geil andE. A. Collins,J. Macromol. Sci. Phys. B14 (1977) 29.

M. Thompson andJ. R. White,Polymer Eng. Sci. 24 (1984) 227.

C. S. Hindle, K. Thomas andJ. R. White, to be published.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Qayyum, M.M., White, J.R. Weathering of injection-moulded glassy polymers: changes in residual stress and fracture behaviour. J Mater Sci 20, 2557–2574 (1985). https://doi.org/10.1007/BF00556088

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00556088