Abstract

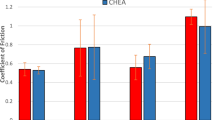

Pin-on-disc dry sliding tests were carried out to study the wear mechanisms in a range of metal-matrix composites. 6061-aluminium alloys reinforced with 10 and 20 vol% SiC and Al2O3 particles were used as pin materials, and a mild steel disc was used as a counterface. A transition from mild wear to severe wear was found for the present composites; the wear rate increased by a factor of 102. The effects of the ceramic particles on the transition load and wear with varying normal pressure were thoroughly investigated. Three wear mechanisms were identified: abrasion in the running-in period, oxidation during steady wear at low load levels, and adhesion at high loads. A higher particle volume fraction raised the transition load but increased the wear rate in the abrasion and adhesion regimes. Increase of particle size was more effective than increase of volume fraction to prolong the transition from mild wear to adhesive wear. The reasons for different wear mechanisms were determined by analyses of the worn surfaces and wear debris.

Similar content being viewed by others

References

K. H. ZUM GAHR, Microstructures and Wear of Materials”, Tribology Series 10 (Elsevier, Amsterdam, 1987).

A. G. WANG and H. J. RACK, Wear 146 (1991) 337.

K. J. BHANSALI and R. MEHRABIAN, J. Metals 34 (1982) 30.

Z. F. ZHANG, Y. X. CHEN, A. K. MUKHOPADHYAY and Y -W. MAI. in “Proceedings of the 3rd Australian Forum on Metal Matrix Composites”, (MMC-3), edited by S. BANDYOPADHYAY and A. G. CROSKY (University of New South Wales, Sydney, 1992) pp. 63–73.

A. G. WANG and H. J. RACK, Wear 147 (1991) 355.

J. ZHANG and A. T. ALPAS, Mater. Sci. Eng. A161 (1993) 273.

A. T. ALPAS and J. ZHANG, Wear 155 (1992) 83.

A. T. ALPAS, H. HU and J. ZHANG, ibid. 162–164 (1993) 188.

Y. S. CHIAO, F. M. PAN, C. A. LIN and J. L. HORNG, ibid. 61 (1993) 155.

F. M. HOSKING, F. FOLGARPORTILLO, R. WUNDERLIN and R. MEHRABIAN, J. Mater. Sci 17 (1982) 477.

A. T. ALPAS and J. D. EMBURY, “Wear of Materials”, (ASME, New York, 1991) pp. 159–166.

N. SAKA and D. P. KARALEKAS, “Wear of Materials”, (ASME, New York, 1985) pp. 784–93.

A. F. SMITH, Wear 105 (1985) 91.

S. JAHANMIR, N. P. SUH and E. P. ABRAHAMSON, ibid. 32 (1975) 33.

Z. F. ZHANG, L. C. ZHANG and Y.-W. MAI, J. Mater. Sci. 30 (1995) in press.

M. J. HADIANFARD, G. HENESS, J. HEALY and Y.-W. MAI, Fatigue Fract. Eng. Mater. Struct. 17 (1994) 253.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Zhang, Z.F., Zhang, L.C. & Mai, Y.W. Wear of ceramic particle-reinforced metal-matrix composites. JOURNAL OF MATERIALS SCIENCE 30, 1961–1966 (1995). https://doi.org/10.1007/BF00353018

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF00353018