Abstract

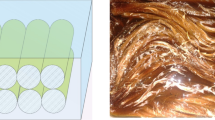

Natural fibre reinforced thermoplastic composite materials are becoming very popular in the material community due to several advantages of natural fibre and thermoplastic polymer. The demand of stronger and better composite than the existing ones is also increasing simultaneously with their growing popularity. However, natural fibre reinforced thermoplastics have some disadvantages associate with the poor fibre-matrix interaction, short length of the natural fibres and high melt viscosity of thermoplastic resins. All these factors decrease the ultimate mechanical properties of the natural fibre composites. However, the surface treatment of natural fibres, use of low twisted yarn and hybrid yarn during composite manufacturing significantly improve the mechanical properties of the natural fibre composites. The scope of all three approaches in determining composites mechanical properties have been reviewed here. Finally, the combined effects of interface and DREF spun hybrid yarn structure on the tensile and flexural properties of flax-PP based unidirectional composite specimen have been discussed in this chapter.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pickering, K. L., Efendy, M. G. A., & Le, T. M. (2016). A review of recent developments in natural fibre composites and their mechanical performance. Composites Part A, 83, 98–112.

Netravali, A. N., & Chabba, S. (2003). Composites get greener. Materials Today, 6(4), 22–29.

Pandey, J. K., Nagarajan, V., Mohanty, A. K., et al. (2015). Commercial potential and competitiveness of natural fiber composites. In M. Misra, J. K. Pandey, & A. K. Mohanty (Eds.), Biocomposites: Design and mechanical performance (pp. 1–15). Cambridge, England: Woodhead Publishing.

Joshi, S. V., Drzal, L. T., Mohanty, A. K., et al. (2004). Are natural fiber composites environmentally superior to glass fiber reinforced composites? Composites Part A, 35, 371–376.

Wambua, P., Ivens, J., & Verpoest, I. (2003). Natural fibres: Can they replace glass in fibre reinforced plastics? Composites Science and Technology, 63, 1259–1264.

John, M. J., & Thomas, S. (2008). Biofibres and biocomposites. Carbohydrate Polymers, 71, 343–364.

Gurunathan, T., Mohanty, S., & Nayak, S. K. (2015). A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Composites Part A, 77, 1–25.

Bar, M., Alagirusamy, R., & Das, A. (2015). Flame retardant polymer composite. Fibres and Polymers, 16(4), 705–715.

Faruk, O., Bledzki, A. K., Fink, H. P., et al. (2012). Biocomposites reinforced with natural fibers: 2000–2010. Progress in Polymer Science, 37, 1552–1596.

Dittenber, D. B., & GangaRao, H. V. S. (2012). Critical review of recent publications on use of natural composites in infrastructure. Composites Part A, 43, 1419–1429.

Pickering, K., Beckermann, G., Alam, S., et al. (2007). Optimizing industrial hemp fibre for composites. Composites Part A, 38, 461–468.

Pandey, J. K., Ahn, S. H., Lee, C. S., et al. (2010). Recent advances in the application of natural fiber based composites. Macromolecular Materials and Engineering, 295(11), 975–989.

Alves, C., Ferrao, P. M. C., Silva, A. J., et al. (2010). Ecodesign of automotive components making use of natural jute fiber composites. Journal of Cleaner Production, 18, 313–327.

Koronis, G., Silva, A., & Fontul, M. (2013). Green composites: A review of adequate materials for automotive applications. Composites Part B, 44, 120–127.

Davoodi, M. M., Sapuan, S. M., Ahmad, D., et al. (2010). Mechanical properties of hybrid kenaf/glass reinforced epoxy composite for passenger car bumper beam. Materials and Design, 31(10), 4927–4932.

Ali, A., Shaker, K., Nawab, Y., et al. (2016). Hydrophobic treatment of natural fibers and their composites—A review. Journal of Industrial Textiles, 1–33 doi:10.1177/1528083716654468.

Mohanty, A. K., Misra, M., & Drzal, L. T. (2002). Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. Journal of Polymers and the Environment, 10, 19–26.

Alagirusamy, R., Fangueiro, R., & Ogale, V. (2006). Hybrid yarns and textile preforming for thermoplastic composites. Textile Progress, 38(4), 1–71.

Torres, F. G., & Cubillas, M. L. (2005). Study of the interfacial properties of natural fibre reinforced polyethylene. Polymer Testing, 24, 694–698.

Zafeiropoulos, N. E., Baillie, C. A., & Hodgkinson, J. M. (2002). Engineering and characterisation of the interface in flax fibre/polypropylene composite materials. Part II. The effect of surface treatments on the interface. Composites: Part A, 33, 1185–1190.

Lu, J. Z., Wu, Q., & McNabb, H. S. (2000). Chemical coupling in wood fiber and polymer composites: A review of coupling agents and treatments. Wood and Fiber Science, 32(1), 88–104.

Chen, P., Lu, C., & Yu, Q. (2006). Influence of fiber wettability on the interfacial adhesion of continuous fiber-reinforced PPESK composite. Journal of Applied Polymer Science, 102(3), 2544–2551.

Matthews, F. L., & Rawlings, R. D. (1999). Composite materials: Engineering and science. Cambridge, England: Woodhead Publishing.

de Farias, J. G. G., Cavalcante, R. C., & Canabarro, B. R. (2017). Surface lignin removal on coir fibers by plasma treatment for improved adhesion in thermoplastic starch composites. Carbohydrate Polymers, 165, 429–436.

Yanjun, X., Callum, A. S. H., Zefang, X., et al. (2010). Silane coupling agents used for natural fiber/polymer composites: A review. Composites Part A, 41, 806–819.

Mohanty, A. K., Khan, M. A., & Hinrichsen, G. (2000). Surface modification of jute and its influence on performance of biodegradable jute-fabric/biopol composites. Composites Science and Technology, 60(11), 15–24.

Bera, M., Alagirusamy, R., & Das, A. (2010). A study on interfacial properties of jute-PP composites. Journal of Reinforced Plastics and Composites, 29, 3155–3161.

Kabir, M. M., Wang, H., & Lau, K. T. (2012). Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Composites Part B, 43(7), 2883–2892.

Beckermann, G. W., & Pickering, K. L. (2008). Engineering and evaluation of hemp fibre reinforced polypropylene composites: Fibre treatment and matrix modification. Composites Part A, 39(6), 979–988.

Gomes, A., Matsuo, T., Goda, K., et al. (2007). Development and effect of alkali treatment on tensile properties of curaua fiber green composites. Composites Part A, 38(8), 1811–1820.

Mukhopadhyay, S., & Fangueiro, R. (2009). Physical modification of natural fibers and thermoplastic films for composites—A review. Journal of Thermoplastic Composite Materials, 22, 135–163.

Yuan, X., Jayaraman, K., & Bhattacharyya, D. (2004). Effect of plasma treatment in enhancing the performance of woodfibre-Polypropylene composite. Composites Part A, 35, 1363–1374.

Belgacem, M. N., Bataille, P., & Sapieha, S. (1994). Effect of corona modification on cellulose/PP composites. Journal of Applied Polymer Science, 53, 379–385.

Huber, T., Biedermann, U., & Muessig, J. (2010). Enhancing the fibre matrix adhesion of natural fibre reinforced polypropylene by electron radiation analyzed with the single fibre fragmentation test. Composite Interfaces, 17(4), 371–381.

Laine, J. E., & Goring, D. A. I. (1977). Influence of ultrasonic irradiation on the properties of cellulosic fibers. Cellulose Chemistry and Technology, 11(5), 561–567.

Bledzki, A. K., Mamun, A. A., & Jaszkiewicz, A. (2010). Polypropylene composites with enzyme modified abaca fibre. Composites Science and Technology, 70, 854–860.

Goutianos, S., Peijs, T., & Nystrom, B. (2006). Development of flax fibre based textile reinforcements for composite applications. Applied Composite Materials, 13(4), 199–215.

Shah, D. U. (2016). Damage in biocomposites: Stiffness evolution of aligned plant fibre composites during monotonic and cyclic fatigue loading. Composites Part A, 83, 160–168.

Amor, I. B., Rekik, H., & Kaddami, H. (2010). Effect of Palm tree fiber orientation on electrical properties of palm tree fiber-reinforced polyester composites. Journal of Composite Materials, 44(13), 1553–1568.

Norman, D. A., & Robertson, R. E. (2003). The effect of fiber orientation on the toughening of short fiber-reinforced polymers. Journal of Applied Polymer Science, 90(10), 2740–2751.

Santamala, H., Livingston, R., Sixta, H., et al. (2016). Advantages of regenerated cellulose fibres as compared to flax fibres in the processability and mechanical performance of thermoset composites. Composites Part A, 84, 377–385.

Kobayashi, S., & Takada, K. (2013). Processing of unidirectional hemp fiber reinforced composites with micro-braiding technique. Composites Part A, 46, 173–179.

Ma, H., Li, Y., & Luo, Y. (2011). The effect of fiber twist on the mechanical properties natural fiber reinforced composites. In 18th International Conference on Composite Materials.

Omrani, F., Wang, P., Soulat, D., et al. (2017). Mechanical properties of flax-fibre-reinforced preforms and composites: Influence of the type of yarns on multi-scale characterization. Composites Part A, 93, 72–81.

Bar, M., Das, A., & Alagirusamy, R. (2017). Studies on flax-polypropylene based low-twist hybrid yarns for thermoplastic composite reinforcement. Journal of Reinforced Plastics and Composites. doi:10.1177/0731684417693428.

Ye, L., Friedrich, K., Kastel, J., et al. (1995). Consolidation of unidirectional CF/PEEK composites from commingled yarn prepreg. Composites Science and Technology, 54(4), 349–358.

George, G., Jose, E. T., Jayanarayanan, K., et al. (2012). Novel bio-commingled composites based on jute/polypropylene yarns: Effect of chemical treatments on the mechanical properties. Composites Part A, 43, 219–230.

Khondker, O. A., Ishiaku, U. S., Nakai, A., et al. (2006). A novel processing technique for thermoplastic manufacturing of unidirectional composites reinforced with jute yarns. Composites Part A, 37, 2274–2284.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2018 Springer International Publishing AG

About this paper

Cite this paper

Bar, M., Alagirusamy, R., Das, A. (2018). Advances in Natural Fibre Reinforced Thermoplastic Composite Manufacturing: Effect of Interface and Hybrid Yarn Structure on Composite Properties. In: Fangueiro, R., Rana, S. (eds) Advances in Natural Fibre Composites. Springer, Cham. https://doi.org/10.1007/978-3-319-64641-1_10

Download citation

DOI: https://doi.org/10.1007/978-3-319-64641-1_10

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-64640-4

Online ISBN: 978-3-319-64641-1

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)