Abstract

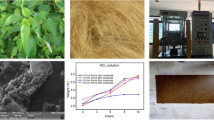

Generally, glass and carbon fibres are most widely used materials in composites. In this study it has been aimed to use flax fibres in composite materials and to study the mechanical properties of the produced samples. The research was carried out with 100 % unbleached flax fibres at different reinforcement ratios to produce hand lay-up composite materials. The produced composite samples were then characterized using three point bending and Izod impact tests. The fracture surfaces of the reinforced composite samples were also inspected with the help of SEM. Both the mechanical tests results (impact and three point bending) and SEM micrographs indicated flax fibres as an alternative natural fibre source for developing reinforced composites for various industries. Good mechanical properties i.e. 109–165 MPa were obtained as compared to the pure resin (≈40 MPa). The flax fibre reinforced composites offered an impact strength of about 21–38 kJ/m2. Finally, fibre/matrix-interface bonding in the composites was improved by the de-waxing process of flax fibres prior to composite fabrication.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Pavithran C, Mukherjee P.S, Brahmakumar M, Damodaran A, Impact properties of natural fibre composites, Journal of Materials Science Letters, 1987, 6, 8 p.882-884.

Mohanty AK, Misra M, Drzal LT, Selke SE, Harte BR, Hinrichsen G. In: Mohanty AK, Misra M, Drzal LT, editors. Natural fibres, biopolymers, and biocomposites: an introduction in natural fibres, natural fibres, biopolymers, and biocomposites, Boca Raton, FL: CRC Press, Taylor & Francis Group; 2005. p. 1–36.

Yan LB, Chouw N, Yuan XW. Improving the mechanical properties of natural fibre fabric reinforced epoxy composites by alkali treatment, Journal of Reinforced Plastics and Composites, 2012, 31, 6, p.425–37.

Okuba K, Fujii T, Yamamoto Y, Development of bamboo-based polymer composites and their mechanical properties, Composite Part A: Applied Science and Manufacturing, 2004, 35, p.377-383.

Yukseloglu, SM, Yoney, H, Bamboo fibre reinforced composite structures and their mechanical properties, Tekstil ve Konfeksiyon, 2009, 19, 4, p.261-264.

Carus M, Scholz L, Targets for bio-based composites and natural fibres, Biowerkstoff report, 8th Edition, ISSN 1867-1217, March 2011 p. 24.

Lucas, A, Harris, JR, Ancient Egyptian materials and industries, Dover Publications, Mineola, New York, 4th Edition, ISBN 0-486-40446-3, 1962 p.142-146.

Bos, HL, Van Den Oever, MJA, Peters, OCJJ, Tensile and compressive properties of flax fibres for natural fibre reinforced composites, Journal of Material Science, 37, 2002, p.1683-1692.

Baley C, Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase, Composites Part A: Applied Science and Manufacturing, 2002, 33, 7, p.939–948.

Bastra SK. Other long vegetable fibres, In: Lewin M, Pearce EM, editors. Handbook of fibre science and technology, Fibre chemistry, New York: Marcel Dekker; 1998 p. 505–575.

Troger F, Wegener G, Seemann C. Miscanthus and flax as raw material for reinforced particle boards. Ind Crops Prod 1998, 8,2, p.113–121.

Lilholt H, Toftegaard H, Thomsen AB, Schmidt AS. Natural composites based on cellulosic fibres and polypropylene matrix. Their processing and characterization. In: Proceedings of ICCM 12, Paris; July 1999, p. 9.

Charlet K, Jernot JP, Gomina M, Bréard J, Morvan C, Baley C. Influence of an Agatha flax fibre location in a stem on its mechanical, chemical and morphological properties. Compos Sci Technol 2009, 69, 9, p.1399–1403.

Srinivasan VS, Boopathy SR, Sangeetha D, Ramnath BV, Evaluation of mechanical and thermal properties of banana-flax based natural fibre composite, Materials and Design, 2014, 60, p.620-627.

Jolly, M., http://www.norafin.com/fileadmin/user_upload/Norafin/Composites/The_Advantages_of_Flax_Fiber_in_Composites_-_Fiber_Congress_2009.pdf, accessed date: 24.12.2014.

Brouwer WD, Natural fibre composites: where can flax compete with glass?, SAMPE J,2000, 36, p.18-23.

Mohanty AK, Misra M, Hinrichsen G, Biofibres, biodegradable polymers and biocomposites: An overview, Micromolecular Materials Engineering, 2000, 276-277, 1, p.1-24.

Prasad AVR, Rao KM, Mechanical properties of natural fibre reinforced polyster composites: Jowar, sisal and bamboo, Materials and Design, 2011, 32, p.4658-4663.

Hodzic A, Shanks R, Natural fibre composites, Materials, processes and properties, Woodhead Publishing Limited, Alma Hodzic and Robert Shanks (ed), 2014, ISBN 978-0-85709-922-8 (online), p.10.

Placet V, Trivaudey F, Cisse O, Gucheret-Retel V, Boubakar ML, Diameter dependence of the apparent tensile modulus of hemp fibres: A morphological, structural or ultra structural effect?, Composites Part A, 2012, 43, p.275-287.

ASTM D 3822, Standard test method for tensile properties of single textile fibres.

TS EN ISO 180, 2006, “Plastics-Determination of Izod Impact Strength”,Turkish Standards Institute, Ankara, Turkey.

TS 985 EN ISO 178, 2006, “Plastics-Determination of Flexural Properties”,Turkish Standards Institute, Ankara, Turkey.

Acknowledgments

The authors are grateful to Elsevier Publishers and authors who permitted to re-produced Fig. 1 and Table 1 from their publications. Also, the first author wishes to thank for the financial support for this research which was provided by the Scientific Research Project Unite of Marmara University project grant FEN-D-110315-0071 of 2015.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2016 RILEM

About this paper

Cite this paper

Yukseloglu, S.M., Yoney, H. (2016). The Mechanical Properties of Flax Fibre Reinforced Composites. In: Fangueiro, R., Rana, S. (eds) Natural Fibres: Advances in Science and Technology Towards Industrial Applications. RILEM Bookseries, vol 12. Springer, Dordrecht. https://doi.org/10.1007/978-94-017-7515-1_19

Download citation

DOI: https://doi.org/10.1007/978-94-017-7515-1_19

Published:

Publisher Name: Springer, Dordrecht

Print ISBN: 978-94-017-7513-7

Online ISBN: 978-94-017-7515-1

eBook Packages: EngineeringEngineering (R0)