Abstract

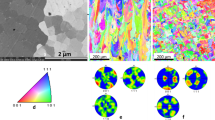

The heat treatment response of the new superalloy ABD-900AM, designed specifically for additive manufacturing (AM), is studied. The as-fabricated microstructure is characterised at multiple length-scales including by X-ray synchrotron diffractometry and transmission Kikuchi diffraction imaging. The very high cooling rates arising during the process suppress γ′ precipitation; thus the details of heat treatment are shown to be important in establishing properties. The yield stress and tensile strength developed are marginally improved by super-solvus rather than sub-solvus heat treatment, but the ductility is then compromised. The tensile behaviour is superior to the heritage alloy IN939 which has a comparable fraction of γ′; this is due to the larger refractory content of ABD-900AM and its finer scale precipitation. The internal strains developed during processing are sufficient to promote recrystallization during super-solvus heat treatment which breaks down microstructural anisotropy and promotes grain growth; however, this effect is absent for the sub-solvus case.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Frazier WE (2014) Metal additive manufacturing: A review. J. Mater. Eng. 23:1917–1928.

Carter LN (2013) Selective laser melting of nickel superalloys for high temperature applications, Ph.D. thesis, University of Birmingham.

Chauvet E, Kontis P, Jagle EA, Gault B, Raabe D, Tassin C, Blandin J, Dendievel R, Vayre B, Abed S, Martin G (2018) Hot cracking mechanism affecting a non-weldable Ni-based superalloy produced by selective electron beam melting. Acta Mater. 142:82–94.

Reed RC, Tao T, Warnken N (2009) Alloys-by-design: application to nickel-based single crystal superalloys. Acta Mater. 57(19):5898–5913.

Harrison NJ, Tood I, Mumtaz K (2015) Reduction of micro-cracking in nickel superalloys processed by selective laser melting: A fundamental alloy design approach. Acta mater. 94:59–68.

Crudden DJ, Nemeth AAN. A nickel-based alloy. International Patent Application Patent WO2019021015A1.

Wang Y, Dong J, Zhang M, Zhihao Y (2016) Stress relaxation behavior and mechanism of AEREX350 and Waspaloy superalloys. Mater. Sci. Eng. A. 678:10–22.

Li HY, Sun JF, Hardy MC, Evans HE, Williams SJ, Doel TJA, Bowen P (2015) Effects of microstructure on high temperature dwell fatigue crack growth in a coarse grain PM nickel based superalloy. Acta Mater. 90:355–369.

Tang YT, Karamched P, Liu J, Haley JC, Reed RC and Wilkinson AJ (2019) Grain boundary serration in nickel alloy inconel 600: Quantification and mechanisms. Acta Mater. 181:352–366.

Collins DM, Crudden DJ, Alabort E, Connolley T, Reed RC (2015) Time-resolved synchrotron diffractometry of phase transformations in high strength nickel-based superalloys. Acta Mater. 94:244–256.

Sulzer S, Alabort E, Nemeth AAN, Roebuck B and Reed RC (2018) On the rapid assessment of mechanical behavior of a prototype nickel-based superalloy using small-scale testing,” Metall. Mater. Trans. A. 49:4214–4235.

Ghoussoub JN, Tang YT, Panwisawas C, Nemeth AAN, Reed RC (2020) On the influence of alloy chemistry and processing conditions on additive manufacturability of Ni-based superalloys. Paper presented at the 14th International Symposium on Superalloys (Superalloys2020), Pennsylvania, September 13–17 2020.

Basoalto HC, Panwisawas C, Sovani Y, Anderson MJ, Turner RP, Saunders B Brooks JW (2018) A computational study on the three-dimensional printability of precipitate-strengthened nickel-based superalloys. P. Roy. Soc. A. 474(2220):1–23.

Hooper PA (2018) Melt pool temperature and cooling rates in laser powder bed fusion. Addit Manuf. 22:548–559.

Jahangiri MR, Boutorabi SMA, Arabi H (2012) Study on incipient melting in cast Ni base IN939 superalloy during solution annealing and its effect on hot workability. Mater. Sci. Technol. 28(12):1402–1413.

Gibbons TB, Stickler R (1982) IN939: Metallurgy, Properties and Performance. Paper presented at the High Temperature Alloys for Gas Turbines 1982, Belgium, 4–6 October 1982.

Mishima Y, Ochiai S, Hamao N. Yodogawa M, Suzuki T (1986) Solid solution hardening of nickel – Role of transition metal and B-subgroup solutes. Trans. Jpn. Inst. Met. 27(9):656–664.

Christofidou KA et al (2018) On the effect of Nb on the microstructure and properties of next generation polycrystalline powder metallurgy Ni-based superalloys. Metall. Mater. Trans. A. 49:3896–3907.

Nemeth AAN, Crudden DJ, Collins DM, Liebscher CH, Armstrong DE, Wilkinson AJ, Reed RC (2018) On the influence of Nb/Ti ratio on environmentally-assisted crack growth in high-strength nickel-based superalloys. Metall. Mater. Trans. A. 49:3923–3937.

Acknowledgements

The financial support of this work via the Innovate UK and OxMet Technologies Ltd is acknowledged by the authors. Y.T. Tang acknowledges Dr. Jack Haley on technical assistance of specimen preparation. The authors are grateful to Elements Materials Technologies for carrying out testing under ASTM standards. The authors also acknowledge beam time allocated to them under award MG23674 at the Diamond Light Source.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 The Minerals, Metals & Materials Society

About this paper

Cite this paper

Tang, Y.T. et al. (2020). The Effect of Heat Treatment on Tensile Yielding Response of the New Superalloy ABD-900AM for Additive Manufacturing. In: Tin, S., et al. Superalloys 2020. The Minerals, Metals & Materials Series. Springer, Cham. https://doi.org/10.1007/978-3-030-51834-9_103

Download citation

DOI: https://doi.org/10.1007/978-3-030-51834-9_103

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-030-51833-2

Online ISBN: 978-3-030-51834-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)