Abstract

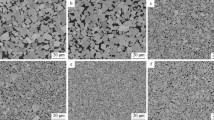

The microstructure, properties and applications of WC-Co cemented carbide prepared with WC powders with different crystallinity were compared. The results show that the crystallinity of different WC powders can be well characterized by XRD, SEM and laser particle size measurements. The hardness of the cemented carbide prepared with WC powders with a high crystallinity decreases slightly, while the fracture toughness, transverse rupture strength, crushing strength and impact toughness increase. The preparation of a raw WC material with a high-crystallinity is the basis of a high-performance cemented carbide.

Similar content being viewed by others

REFERENCES

Herber, R.-P., Schubert, W.-D., and Lux, B., Hardmetals with “rounded” WC grains, Int. J. Refract. Met. Hard Mater., 2006, vol. 24, pp. 360–364.

Christensen, M., Wahnstrom, G., and Lay, S., Morphology of WC grains in WC–Co alloys: theoretical determination of grain shape, Acta Mater., 2007, vol. 55, pp. 1515–1521.

Shatov, A.V., Firstov, S.A., and Shatova, I.V., The shape of WC crystals in cemented carbides, Mater. Sci. Eng., A, 1998, vol. 242, pp. 7–14.

Shatov, A.V., Ponomarev, S.S., and Firstov, S.A., Fracture of WC–Ni cemented carbides with different shape of WC crystals, Int. J. Refract. Met. Hard Mater., 2008, vol. 26, pp. 68–76.

Zhu, L., Liu, K., and Li, Z., Study on the hardening and toughening mechanisms of WC–Co cemented carbides with plate-like WC grains, Rare Met. Mater. Eng., 2011, vol. 40, pp. 443–446.

Li, Z. and Zhu, L., Microstructure and properties of WC-10%Co cemented carbides with plate-like WC grains, J. Cent. South Univ., Sci. Technol., 2010, vol. 41, pp. 521–525.

Xhang, J., Effect of reduction and carbonization temperature of tungsten powder on WC phase substructure and mechanical properties of tungsten-cobalt alloy, Cem. Carbide, 1990, vol. 1, pp. 1–7.

Bondarenko, N.A., Zhukovsky, A.N., and Mechnik, V.A., Analysis of the basic theories of sintering of materials. 1. Sintering under isothermal and nonisothermal conditions (a review), Sverkhtverd. Mater., 2006, vol. 6. pp. 3–17.

Lisovsky, A.F., Formation of mesostructure in WC–Co cemented carbides (a review), Sci. Sintering, 2011, vol. 43, vol. 2, pp. 161–173.

Lisovsky, A.F., On the formation of a refractory skeleton in composite materials. A review, J. Superhard Mater., 2013, vol. 35, vol. 2, pp. 65–76.

Lisovsky, A.F. and Bondarenko, N.A., The role of interphase and contact surfaces in the formations of structures and properties of diamond-(WC-Co) composites. A review, J. Superhard Mater., 2014, vol. 36, vol. 3, pp. 145–155.

Kolodnits’kyi, V.M. and Bagirov, O.E., On the structure formation of diamond-containing composites used in drilling and stone-working tools (A review), J. Superhard Mater., 2017, vol. 39, no. 1, pp. 1–17.

Bondarenko, N.A., Novikov, N.V., Mechnik, V.A., et al., Structural peculiarities of highly wear-resistant superhard composites of the diamond–WC–6Co carbide system, Sverkhtverd. Mater., 2004, vol. 6, pp. 3–15.

Novikov, N.V., Bondarenko, N.A., Zhukovskii, A.N., et al., The effect of diffusion and chemical reactions on the structure and properties of drill bit inserts. 1. Kinetic description of systems Cdiamond-VK6 and Cdiamond-(VK6-CrB2-W2B5), Fiz. Mezomekh., 2005, vol. 8, vol. 2, pp. 99–106.

Bondarenko, N.A. and Mechnik, V.A., The influence of transition area diamond-matrix on wear resistance and operation properties of drilling tool produced by ISM, SOCAR Proc., 2011, vol. 2, pp. 18–24.

Bondarenko, N.A. and Mechnik, V.A., Drilling oil and gas wells by ISM diamond tools, SOCAR Proc., 2011, vol. 3, pp. 6–12.

Aleksandrov, V.A., Alekseenko, N.A., and Mechnik, V.A., Study of force and energy parameters in cutting granite with diamond disc saws, Sverkhtverd. Mater., 1984, no. 6, pp. 46–52.

Dutka, V.A., Kolodnitskii, V.M., Zabolotnyi, S.D., et al., Simulation of the temperature level in rock destruction elements of drilling bits, Sverkhtverd. Mater., 2004, vol. 2, pp. 66–73.

Dutka, V.A., Kolodnitskii, V.M., Mel’nichuk, O.V., Zabolotnyi, S.D. et al., Mathematical model for thermal processes occurring in the interaction between rock destruction elements of drilling bits and rock mass, Sverkhtverd. Mater., 2004, vol. 2, pp. 66–73.

Zhukovsky, A.N., Maystrenko, A.L., Mechnik, V.A., et al., Stress-strain state of the bond in the neighborhood of the diamond grain that is under the actions of the normal and tangent components of the load. Part 1. Model, J. Frict. Wear, 2002, vol. 23, no. 2, pp. 146–153.

Zhukovsky, A.N., Maystrenko, A.L., Mechnik, V.A., et al., Stress-strain state of the bond in the neighborhood of the diamond grain that is under the actions of the normal and tangent components of the load. Part 2. Analysis, J. Frict. Wear, 2002, vol. 23, no. 4, pp. 393–396.

Sveshnikov, I.A. and Kolodnitskii, V.N., Optimization of the hard alloy cutter arrangement in the drilling bit body, Sverkhtverd. Mater., 2006, vol. 4, pp. 70–75.

Mechnik, V.A., Bondarenko, N.A., Dub, S.N., Kolodnitskyi, V.M., et al., A study of microstructure of Fe-Cu-Ni-Sn and Fe-Cu-Ni-Sn-VN metal matrix for diamond containing composites, Mater. Charact., 2018, vol. 146, pp. 209–216.

Mechnik, V.A., Bondarenko, N.A., Kolodnitskyi, V.M., et al., Physico-mechanical and tribological properties of Fe-Cu-Ni-Sn and Fe-Cu-Ni-Sn-VN nanocomposites obtained by powder metallurgy methods, Tribol. Ind., 2019, Vol. 41, no. 2, pp. 188–198.

GB 3851-83: Hard Alloy Bending Strength Measuring Method, Beijing: China Stand. Press, 1983, pp. 189–194.

Roebuck, B., Measuring WC grain size distribution, Metal Powder Rep., 1999, vol. 54, pp. 20–24.

Nie, H., Wu, C., Zeng, Q., et al., CN Patent 201210286816.6, 2012.

Wu, C., Nie, H., Zeng, Q., et al., Microstructure and mechanical properties of extra coarse grained cemented carbides, Mater. Sci. Eng. Powder Metall., 2013, vol. 18, pp. 198–204.

Ely, D.R., Edwin García, R., and Thommes, M., Ostwald–Freundlich diffusion-limited dissolution kinetics of nanoparticles, Powder Technol., 2014, vol. 257, pp. 120–123.

Nie, H., Zeng, Q., Zheng, J., et al., The preparation, preparation mechanism and properties of extra coarse-grained WC–Co hardmetals, Met. Powder Rep., 2017, vol. 72, pp. 188–194.

Wu, Y.F., Study on mechanism of phase transformation in binder phase, Cem. Carbide, 2004, vol. 21, pp. 65–69.

Mingard, K.P., Roebuck, B., Bennett, E.G., et al., Comparison of EBSD and conventional methods of grain size measurement of hardmetals, Int. J. Refract. Met. Hard Mater., 2009, vol. 27, pp. 213–223.

Mingard, K.P., Roebuck, B., Marshall, J., et al., Some aspects of the structure of cobalt and nickel binder phases in hardmetals, Acta Mater., 2011, vol. 59, pp. 2277–2290.

Xie, C., Zhou, H., and Yu, P., Study on shear mechanism and microstructure of cobalt binder phase, Cem. Carbide, 2013, vol. 30, pp. 242–248.

Beste, U., Hartzell, T., Engqvist, H., et al., Surface damage on cemented carbide rock-drill buttons, Wear, 2001, vol. 249, pp. 324–329.

Liang, D.B., US Patent 6 197 084, 2001.

Kindermann, P., Schlund, P., Sockel, H.G., et al., High-temperature fatigue of cemented carbides under cyclic loads, Int. J. Refract. Met. Hard Mater., 1999, vol. 17, pp. 55–68.

Zhang, L., Wang, Y., Yu, X., et al., Effect of particle size and morphology of tungsten carbide powder on grain size, grain morphology and properties of cemented carbide, China Tungsten Ind., 2008, vol. 23, pp. 23–26.

Funding

We gratefully acknowledge the financial support of the funding for (Science and Technology Major Project of Fujian) under grant (2017HZ0001-1).

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Zhongnan Xiang, Li, Z., Nie, H. et al. Effect of Crystallinity of WC on Microstructure, Properties, and Application of WC-Co Cemented Carbide. J. Superhard Mater. 43, 21–30 (2021). https://doi.org/10.3103/S106345762101007X

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S106345762101007X