Abstract

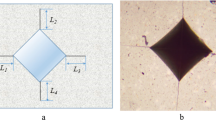

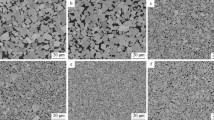

In this paper, the microstructure and mechanical properties of 90WC-8Ni 2Cr3C2 cemented carbide, developed by powder metallurgy, were investigated using optical and scanning electron microscopy, XRD, and hardness tester. The results showed that the addition of 2 wt% Cr3C2 in the WC-Ni alloy system, using conventional adding method, was not favorable to densification. The porosity was characterized by the presence relatively large elongated pores distributed in the microstructure. As a result, there were not significant improvement of the hardness and flexural strength of the WC-8Ni-2 Cr3C2 cemented carbide in comparison with WC-10Ni cemented carbides without Cr3C2 addition, obtained from the literature. Fracture toughness results showed that the cemented carbide WC-8Ni-2Cr3C2 presented higher fracture toughness than that of WC-Co, WC-Co-2Cr3C2, and WC-Ni alloys from literature, which may be mainly attributed to the effectiveness of Cr3C2 to inhibit the excessive grain growth of the WC particles, producing a more refined and tough microstructure. Thus, despite the porosity, the mechanical properties values obtained of the developed 90WC-8Ni-2Cr3C2 cemented carbide are adequate for several engineering applications, where is required a good balance between hardness, wear resistance, and toughness.

Similar content being viewed by others

References

Kai-hua S, Ke-chao Z, Zhi-you L, Xiu-qi Z, Shang-zhi X, Zhao-yu M (2013) Effecting of adding method of Cr on microstructure and properties of WC-9Ni-2Cr cemented carbides. Int J Refract Met Hard Mater 38:1–6

Phuong DD, Trinh PV, Duong LV, Chung LD (2016) Influence of sintering temperature on microstructure and mechanical properties of WC-8Ni cemented carbide produced by vacuum sintering. Ceram Int 42:14937–14943

Marques BJ, Fernandes CM, Senos AMR (2013) Sintering, microstructure and properties of WC-AISI304 powder composites. Int J Refract Met Hard Mater 562:164–170

Liu J, Ma X, Tang H, Zhao W, Zhao Z (2016) Preparation, microstructure and mechanical properties of bulk (W0.5Al0.5) C0.65 without binder phase by reactive hot-pressing. J. Alloy Compd 679:149–154

Fernandes CM, Senos AMR, Vieira MT, Antunes JM (2008) Mechanical characterization of composites prepared from WC powders coated with Ni rich binders. Int J Refract Met Hard Mater 26:491–498

Gill SS, Singh J, Singh H, Singh R (2012) Metallurgical and mechanical characteristics of cryogenically treated tungsten carbide (WC-Co), Int. J Adv Manuf Technol 58:119–131

Mao C, Ren Y, Gan H, Zhang M, Zhang J, Tang K (2015) Microstructure and mechanical properties of CBN-WC-Co composites used for cutting tools. Int J Adv Manuf Technol 76:2043–2049

Ding X, Cheng XD, Li C, Yu X, Ding ZX, Yaun CQ (2018) Microstructure and performance of multi-dimensional WC-CoCr coating sprayed by HVOF. Int J Manuf Technol 96:1625–1633

Li X, Liu Y, Wei W, Du M, Li K, Zhou J, Fu K (2016) Influence of NbC and VC on microstructure and mechanical properties of WC-Co functionally graded cemented carbides. Mater Design 90:562–567

Genga RM, Cornish LA, Akdogan G (2013) Effect of Mo2C additions on the properties of SPS manufactured WC-TiC-Ni cemented carbides. Inter J. Refract Met Hard Mater 41: 12–21

Balbino NAN, Correa EO, Valeriano LC, Amancio DA (2017) Microstructure and mechanical properties of 90WC-8Ni-2Mo2C cemented carbide developed by conventional powder metallurgy. Inter J Refract Met Hard Mater 68:49–53

Wittmann B, Schubert WD, Lux B (2002) WC grain growth and grain growth inhibition in nickel and iron binder hardmetals. Int J Refract Met Hard Mater 20(1):51–60

Correa EO, Santos JN, Klein AN (2010) Microstructure and mechanical properties of WC-Ni-Si based cemented carbides developed by powder metallurgy. Int J. Refract Met Hard Mater 28:572–575

Correa EO, Santos JN, Klein AN (2011) Microstructure and mechanical properties of WC-Ni-Al based cemented carbides developed for engineering applications. Int J Mat Research 102:1369–1373

Siwak P, Garbiec D, Rogalewicz M (2017) The effect of Cr3C2 and TaC additives on microstructure, hardness and fracture toughness of WC-6Co tool material fabricated by spark plasma sintering. Mater Res 20:780–785

Zackrisson J, Jansson B, Uphadyaya GS, Andrén HO (1998) WC-Co based cemented carbides with large Cr3C2 additions. Int J Refrac Met Hard Mater 16:417–422

Siwak P, Garbiec D (2016) Microstructure and mechanical properties of WC-Co, WC-Co-Cr3C2 and WC-Co-TaC cermets fabricated by spark plasma sintering. Trans Nonferrous Met Soc China 26:2641–2646

Banerjee D, Lal GK, Upadhyaya GS (1995) Effect of binder-phase modification and Cr3C2 addition on properties of WC-10Co cemented carbide. J Mater Engineering Performance 4:563–572

Minutolo FC, Caraviello A (2014) Wear behavior of WC-Co carbides with addition of Cr3C2 and Ni. Key Eng Mater 611-612:444–451

Ojo-kupuluyi OJ, Tahir SM, Azimah Hanim MA, Baharudin BTHT, Matori KA, Anuar MS (2017) Role of carbon addition on the microstructure and mechanical properties of cemented tungsten carbide and steel bilayer. Int Adv Manuf Technol 92:3363–3371

Chicot D, Pertuz A, Roudet F, Staia MH, Lesage J (2004) New developments for fracture toughness determination by Vickers indentation. Mater Sci Technol 20:877–884

Cooper R, Manktelow SA, Wong F, Collins LE (1988) The sintering characteristics and properties of hard metal with Ni-Cr binders. Mater Sci Eng A 105:269–273

Poetschke J, Richter V, Holke R (2012) Influence and effectivity of VC and Cr3C2 grain growth inhibitors on sintering of binderless tungsten carbide. Int J Refract M Hard Mater 31:218–223

Zhixing G, Ji X, Mei Y, Xiangyu S, Cijin J (2008) Effect of Mo2C on the microstructure and properties of WC-TiC-Ni cemented carbide. Inter J Refract Met Hard Mater 26:601–605

Shatov AV, Ponomarev SS, Firstov SA (2008) Fracture of WC-Ni cemented carbides with different shape of WC crystals. Int J Refr Metals Hard Mater 26:68–76

Schatt W, (1985) Powder metallurgy, sintered and composite materials, (Pulvermetallurgie. Sinter-und Verbundwerstaffe), 2. ed., VEB Deutscher Verlag fuer Grundstoffindustrie, Leipzig (in German)

Exner HE, Gurland J (1970) The effect of small plastic deformations on the strength and hardness of a WC-Co alloy. J Mater 5:75–85

Scieszka SF (2001) Wear transition as a means of fracture toughness evaluation of hardmetals. Tribol Lett 11:185–194

Acknowledgements

The authors are grateful to the Brazilian agencies FAPEMIG, CAPES, and CNPq by the financial support to this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balbino, N.A.N., Correa, E.O. & de Carvalho Valeriano, L. Development of the 90WC-8Ni-2Cr3C2 cemented carbide for engineering applications. Int J Adv Manuf Technol 99, 1653–1660 (2018). https://doi.org/10.1007/s00170-018-2511-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2511-y