Abstract

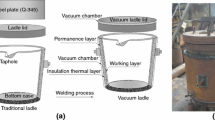

Methods for the ladle treatment of steel in vacuum are briefly reviewed, and the potential of various options is explored. For the most widely used systems, the classification, basic parameters, system composition, design features, problems, and prospects are outlined. Approaches developed at the Russian Scientific-Research Institute of Metallurgical Machinery are briefly described, and some equipment and specific designs developed at the institute are presented.

Similar content being viewed by others

References

Protasov, A.V., Sivak, B.A., and Chichenev, N.A., Agregaty vnepechnoi obrabotki zhidkoi stali: kurs lektsii Mashiny i agregaty metallurgicheskogo proizvodstva (Ladle Treatment of Liquid Steel: Lecture Course in Metallurgical Machines and Systems), Moscow: ID MISiS, 2009.

Protasov, A.V., Pasechnik, N.V., and Sivak, B.A., Oborudovanie dlya vnepechnoi obrabotki stali (Equipment for Ladle Treatment of Steel), Moscow: Intermet Engineering, 2010.

Knuppel, H., Reduction and Vacuum Treatment of Steel, Vol. 2, Ladle-Metallurgy Principles and Technology (Russian translation), Moscow: Metallurgiya, 1984, pp. 172–200.

Maiorov, A.I., Reshetov, V.I., Reshetov, E.I., Protasov, A.V., et al., USSR Inventor’s Certificate 690373, Byull. Izobret., 1982, no. 35.

Parshin, V.M., Protasov, A.V., Zhavoronkov, Yu.I., et al., Flow-Type Vacuum Treatment of Steel for Continuous-Casting Machine at Zaporozhstal’ Metallurgical Works, Chern. Metall.: Byull. NTI, 1993, no. 3, pp. 23–25.

Parshin, V.M., Zhavoronkov, Yu.I., Protasov, A.V., and Lukovnikov, V.S., Vacuum Treatment in Continuous Steel Production, Trudy I kongressa stale-plavil’shchikov, Moskva, 12–15 oktyabrya 1992 g. (Proceedings of First Congress of Steel Smelters, Moscow, October 12–15, 1992), Moscow: AO Chermetinformatsiya, 1993, pp. 237–239.

Protasov, A.V., Revin, E.M., Boiko, Yu.P., et al., Russian Patent 2019570, Byull. Izobret., 1995, no. 17.

Protasov, A.V., Revin, E.M., and Boiko, Yu.P., Russian Patent 2 037532, Byull. Izobret., 1995, no. 17.

Timofeev, V.T., Sapozhnikov, V.I., Moizhim, V.O., Protasov, A.V., et al., Russian Patent 2038188, Byull. Izobret., 1995, no. 18.

Protasov, A.V., Revin, E.M., Parshin, V.M., et al., Russian Patent 2038386, Byull. Izobret., 1995, no. 18.

Afonin, S.Z., Parshin, V.M., Larin, A,V., Protasov, A.V., et al., Russian Patent 2082543, Byull. Izobret., 1997, no. 18.

Reshetov, V.I., Protasov, A.V., Revin, E.M., et al., New Design of Flow-Type Vacuum Treatment System, Tyazhel. Mashinostr., 1996, no. 5, pp. 5–6.

Reshetov, V.I. and Protasov, A.V., Ladle Vacuum Treatment Systems in the Soviet Union and Abroad, Obzor TsNIITEITyazhmash, 1982, no. 31.

Reshetov, V.I. and Protasov, A.V., Trends in the Development of Ladle Vacuum Treatment Systems, Obzor TsNIITEITyazhmash, 1988, series 1, issue 6.

Protasov, A.V., Portion-by-Portion and Circulatory Ladle Vacuum Treatment Systems, Entsiklopediya Mashinostroenie. T. IV-5, Mashiny i agregaty metallurgicheskogo proizvodstva (Encyclopedia of Manufacturing, Vol. IV-5: Metallurgical Production Systems), Moscow: Mashinostroenie, 2000, pp. 109–127.

Shvartsburd, M.G. and Protasov, A.V., Progressive Solutions Used in the Design of the VP-385 Vacuum Treatment System at Magnitogorsk Metallurgical Works, Tyazhel. Mashinostr., 1990, no. 11, pp. 14–17.

Protasov, A.V., Maiorov, A.I., Sivak, B.A., et al., Creation and Industrial Introduction of Integrated Vacuum Treatment Systems, Tyazhel. Mashinostr., 2000, no. 7, pp. 26–30.

Sarychev, A.F., Frolov, V.I., Nikolaev, O.A., et al., Operational Experience with Integrated Vacuum Treatment Systems, Chern. Met., 2000, no. 11, pp. 13–16.

Protasov, A.V., Maiorov, A.I., Sivak, B.A., et al., Creation and Industrial Introduction of Integrated Vacuum Treatment Systems, Trudy VI kongressa stale-plavil’shchikov, Moskva, 17–19 oktyabrya 2000 (Proceedings of Sixth Congress of Steel Smelters, Moscow, October 17–19, 2000), Moscow: AO Chermetinformatsiya, 2001, pp. 395–401.

Motlagh, M., Dehydrogenisation of Steel by DH Vacuum Treatment: An Overview, Steel Times Intern., 1991, July.

Harten, L., Greschupp, Z., and Kessler, R., Improvement in Vacuum Treatment System Technology in the Steel-Smelting Shop at Krupp Hoesch Stahl (Dortmund), Chern. Met., 1997, no. 1, pp. 36–44.

Luk’yanov, A.V., Shchegolev, A.P., Karpukhin, I.I., et al., Industrial Tests of New Ladle Vacuum Treatment System in Steel Smelting at OAO Severstal’, Metallurg, 2008, no. 6, pp. 26–29.

Luk’yanov, A.V., Shchegolev, N.A., Protasov, A.V., and Sivak, B.A., Prospects for Industrial Adoption of Ladle Vacuum Refining of Enlarged VDF/VODF Steel Melts, Nedelya metallov v Moskve, 10–13 noyabrya 2009: sb. tr. konf. (Metals Week in Moscow, November 10–13, 2009: Conference Proceedings), Moscow; VNIImetmash, 2009, pp. 283–290.

Alekseev, V.F., Rybalov, G.V., Protasov, A.V., et al., USSR Inventor’s Certificate 1448677, Byull. Izobret., 2001, no. 10.

Protasov, A.V., Basic Parameters of Portion-by-Portion Vacuum Treatment Systems, Tyazhel. Mashinostr., 2001, no. 5, pp. 13–17.

Maiorov, A.I., Molotkov, I.A., Blokh, V.A., Protasov, A.V., et al., USSR Inventor’s Certificate 773093, Byull. Izobret., 1980, no. 39.

Maiorov, A.I., Reshetov, V.I., and Protasov, A.V., USSR Inventor’s Certificate 1092188, Byull. Izobret., 1984, no. 18.

Protasov, A.V., Basic Parameters of Circulatory Vacuum Treatment Systems, Tyazhel. Mashinostr., 2001, no. 6, pp. 24–27.

Protasov, A.V., Selecting the Basic Parameters of Circulatory Vacuum Treatment Systems, Vysokotekhnologichnoe oborudovanie dlya metallurgicheskoi promyshlennosti: sb. tr. mezhdunar. nauch.-prakt. konf. (High-Technology Equipment for the Metallurgical Industry: Proceedings of an International Conference), Moscow: VNIImetmash, 2004, pp. 86–94.

Protasov, A.V., Development of Portion-by-Portion and Circulatory Vacuum Treatment Systems on Modular Principles, Tyazhel. Mashinostr., 2003, no. 5, pp. 2–6.

Protasov, A.V., Maiorov, A.I., and Komolov, I.V., Rational Selection of Equipment for Ladle Treatment of Steel in an Up-to-Date Steel-Smelting Shop, Chern. Metall.: Byull. NTI, 2006, pp. 58–63.

Author information

Authors and Affiliations

Additional information

Original Russian Text © A.V. Protasov, 2010, published in “Stal’,”; 2010, No. 12, pp. 20–26.

Part 1 was published in Stal’, 2010, no. 10, pp. 22–28.

About this article

Cite this article

Protasov, A.V. Systems for the ladle processing of steel part 2. Vacuum processes. Steel Transl. 40, 1077–1084 (2010). https://doi.org/10.3103/S0967091210120132

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091210120132