Abstract.

A two-dimensional quantitative cellular automaton (CA) model is employed to simulate dendrite arm fragmentation and dendrite arm coarsening in mushy zones. The phenomenon of dendrite arm fragmentation of an Al-Cu alloy during heating is well represented by the CA simulation, and it is analyzed in detail by comparing the local actual concentration and local equilibrium concentration. The CA simulations for the dendritic microstructures of SCN-ACE alloys during isothermal holding in a mushy zone reproduce the typical dendrite coarsening features as observed in experiments. The effects of holding temperature and alloy composition on the microstructures and dendrite coarsening kinetics are investigated. It is found that the melting of small dendrite arms and interdendritic groove advancement are the two main mechanisms in dendrite coarsening. The mechanism of coalescence by joining arm tips is more likely to take place at a lower temperature or for a lower alloy composition, while the dendrite arm fragmentation mechanism tends to occur at a higher temperature. The coarsening rate constant is found to decrease with increasing holding temperature and alloy composition.

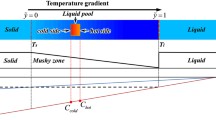

Graphical abstract

Similar content being viewed by others

References

M. Rettenmayr, Int. Mater. Rev. 54, 1 (2009)

S.P. Marsh, M.E. Glicksman, Metall. Mater. Trans. A 27, 557 (1996)

D.J. Rowenhorst, P.W. Voorhees, Annu. Rev. Mater. Res. 42, 105 (2012)

A.M. Mullis, R.F. Cochrane, J. Appl. Phys. 82, 3783 (1997)

M.A. Martorano, C. Beckeckermann, C.A. Gandin, Metall. Mater. Trans. A 34, 1657 (2003)

R.H. Mathiesen, L. Arnberg, P. Bleuet, A. Somogyi, Metall. Mater. Trans. A 37, 2515 (2006)

H. Yasuda, I. Ohnaka, K. Kawasaki, A. Sugiyama, T. Ohmichi, J. Iwane, K. Umetani, J. Cryst. Growth 262, 645 (2005)

M. Schwarz, A. Karma, K. Eckler, D. Herlach, Phys. Rev. Lett. 73, 1380 (1994)

I.M. Lifshitz, V.V. Slyozov, J. Phys. Chem. Solids 19, 35 (1961)

C.T. Wagner, Z. Elektrochem. 65, 581 (1961)

D.H. Kirkwood, Mater. Sci. Eng. A 73, L1 (1985)

K.P. Young, D.H. Kirkwood, Metall. Trans. 6, 197 (1975)

T.Z. Kattamis, M.C. Flemings, Trans. Metall. Soc. AIME 236, 1523 (1966)

J.J. Reeves, T.Z. Kattamis, Scr. Metall. 5, 223 (1971)

M. Chen, T.Z. Kattamis, Mater. Sci. Eng. A 247, 239 (1998)

T.Z. Kattamis, J.C. Coughlin, M.C. Flemings, Trans. AIME 239, 1504 (1967)

M.C. Flemings, T.Z. Kattamis, B.P. Bardes, Trans. Am. Foundry Soc. 89, 501 (1991)

A. Mortensen, Metall. Mater. Trans. A 20, 247 (1989)

S. Terzi, L. Salvo, M. Suery, A.K. Dahle, E. Boller, Acta Mater. 58, 20 (2010)

R. Mendoza, J. Alkemper, P.W. Voorhees, Metall. Mater. Trans. A 54, 481 (2003)

D. Kammer, P.W. Voorhees, Acta Mater. 54, 1549 (2006)

J.L. Fife, P.W. Voorhees, Acta Mater. 57, 2418 (2009)

T. Cool, P.W. Voorhees, Acta Mater. 127, 359 (2017)

K. Jackson, J. Hunt, D. Uhlmann, T. Seward, Trans. Metall. Soc. AIME 236, 149 (1966)

J.L. Fife, J.W. Gibbs, E.B. Gulsoy, C.L. Park, K. Thornton, P.W. Voorhees, Acta Mater. 70, 66 (2014)

E.Y. Guo, A.B. Phillion, B. Cai, S.S. Shuai, D. Kazantsev, T. Jing, Peter D. Lee, Acta Mater. 123, 373 (2017)

B. Li, H. Brody, A. Kazimirov, Metall. Mater. Trans. A 38, 599 (2007)

N. Limodin, L. Salvo, E. Boller, M. Suery, M. Felberbaum, S. Gailliegue, K. Madi, Acta Mater. 57, 2300 (2009)

S.S. Shuai, E.Y. Guo, A.B. Phillion, Mark D. Callaghan, T. Jing, Peter D. Lee, Acta Mater. 118, 260 (2016)

E. Liotti, A. Lui, S. Kumar, Z. Guo, C. Bi, T. Connolley, P.S. Grant, Acta Mater. 121, 384 (2016)

J.C. Wang, G.C. Yang, Acta Mater. 56, 4585 (2008)

C.L. Park, P.W. Voorhees, K. Thornton, Acta Mater. 90, 182 (2015)

T. Cool, P.W. Voorhees, Philos. Trans. A 376, 20170213 (2018)

E. Wesner, A. Choudhury, A. August, M. Berghoff, B. Nestler, J. Cryst. Growth 359, 107 (2012)

M.F. Zhu, D.M. Stefanescu, Acta Mater. 55, 1741 (2007)

S.Y. Pan, M.F. Zhu, Acta Mater. 58, 340 (2010)

L. Beltran-Sanchez, D.M. Stefanescu, Metall. Mater. Trans. A 35, 2471 (2004)

H. Fang, Q.Y. Tang, Q.Y. Zhang, T.F. Gu, M.F. Zhu, Int. J. Heat Mass Transfer 133, 371 (2019)

X.F. Zhang, J.Z. Zhao, H.X. Jiang, M.F. Zhu, Acta Mater. 60, 2249 (2012)

K. Reuther, M. Rettenmayr, Comput. Mater. Sci. 95, 213 (2014)

C.A. Gandin, M. Rappaz, Acta Mater. 45, 2187 (1997)

Q.Y. Zhang, H. Fang, H. Xue, Q.Y. Tang, S.Y. Pan, M. Rettenmayr, M.F. Zhu, Scr. Mater. 151, 28 (2018)

Q.Y. Zhang, H. Xue, Q.Y. Tang, S.Y. Pan, M. Rettenmayr, M.F. Zhu, Comput. Mater. Sci. 146, 204 (2018)

Q.Y. Zhang, H. Fang, H. Xue, S.Y. Pan, M. Rettenmayr, M.F. Zhu, Sci. Rep. 7, 17809 (2017)

M.J.M. Krane, D.R. Johnson, S. Raghavan, Appl. Math. Model. 33, 2234 (2009)

U. Bösenberg, Kornvergröberung in gegenwart von flüssigen filmen an den korngrenzen, PhD Thesis (FSU, Jena, Germany, 2005)

I. Farup, J.M. Drezet, M. Rappaz, Acta Mater. 49, 1261 (2001)

D. An, S.Y. Pan, L. Huang, T. Dai, B. Krakauer, M.F. Zhu, ISIJ Int. 54, 422 (2014)

K.A. Jackson, J.D. Hunt, Acta Metall. 13, 1212 (1965)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

The EPJ Publishers remain neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fang, H., Xue, H., Zhang, Q. et al. Modeling of dendrite arm fragmentation and dendrite arm coarsening⋆. Eur. Phys. J. E 43, 44 (2020). https://doi.org/10.1140/epje/i2020-11968-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epje/i2020-11968-5