Abstract

Many newer higher strength materials are being synthesized for variable automobile, aerospace and manufacturing applications in the present scenario. Since it is very difficult to cut such materials using conventional machining process, it is important to utilize unconventional machining process. In the present study, a detailed survey has been made to analyze the influence of various process parameters, effects of electrodes, optimization and electrolytes on performance measures in Electro chemical machining process. The effects of pulse related parameters on electrode materials, coating materials and its thickness on material removal, overcut and surface topography were investigated under different perspectives such materials, electrolyte and machining parameters. From the detailed literatures, it has been inferred that still lot of research works have been required to find the suitable electrolytes and their combination during the machining process. It has also been found that the performance measures of the machining process can be improved by adopting different and suitable optimization algorithms.

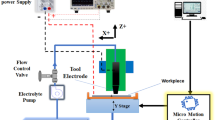

Graphic abstract

Similar content being viewed by others

Data availability

Data sharing is not applicable to this article as no new data were created or analyzed in this study.

Code availability

Not applicable.

References

Huo J, Liu S, Wang Y, Muthuramalingam T, Pi VN. Influence of process factors on surface measures on electrical discharge machined stainless steel using TOPSIS. Mater Res Exp. 2019;6: 086507.

Muthuramalingam T, Mohan B. A review on influence of electrical process parameters in EDM process. Arch Civil Mech Eng. 2014;15(1):87–94.

Thangaraj M, Ramamurthy A, Sridharan K, Ashwin S. Analysis of surface performance measures on WEDM processed titanium alloy with coated electrodes. Mater Res Exp. 2018;5: 126503.

Muthuramalingam T. Measuring the influence of discharge energy on white layer thickness in electrical discharge machining process. Measurement. 2019;131:694–700.

Muthuramalingam T, Vasanth S, Vinothkumar P, Geethapriyan T, Rabik MM. Multi criteria decision making of abrasive flow oriented process parameters in abrasive water jet machining using Taguchi-DEAR Methodology. Silicon. 2018;10(5):2015–21.

Manoj M, Jinu GR, Muthuramalingam T. Multi response optimization of AWJM process parameters on machining TiB2 particles reinforced Al7075 composite using Taguchi-DEAR methodology. Silicon. 2018;10(5):2287–93.

Thangaraj M, Ahmadein M, Alsaleh NA, Elsheikh AH. Optimization of abrasive water jet machining of SiC reinforced aluminum alloy based metal matrix composites using Taguchi–DEAR technique. Materials. 2021;14(21):562–78.

Muthuramalingam T, Moiduddin K, Akash R, Krishnan S, Mian SH, Ameen W, Alkhalefah H. Influence of process parameters on dimensional accuracy of machined Titanium (Ti-6Al-4V) alloy in Laser Beam Machining Process. Opt Laser Technol. 2020;132: 106494.

Thangaraj M. Ravi Akash, Shravan Krishnan, Nguyen Huu Phan, Vu Ngoc Pi, A H Elsheikh, Surface quality measures analysis and optimization on machining titanium alloy using CO2 based Laser beam drilling process. J Manuf Process. 2021;62:1–6.

Masuzawa T. State of the art of micromachining. CIRP Ann. 2000;49:473–88.

Bhattacharyya B, Malapati M, Munda J, Sarkar A. Influence of tool vibration on machining performance in electrochemical micro-machining of copper. Int J Mac Tool Manuf. 2007;47:335–42.

Rajurkar KP, Sundaram MM, Malshe AP. Review of electrochemical and electrodischarge machining. Procedia CIRP. 2013;6:13–26.

Spieser A, Ivanov A. Recent developments and research challenges in electrochemical micromachining (μECM). Int J Adv Manuf Technol. 2013;69:563–81.

Shanmugam R, Ramoni MO, Geethapriyan T, Thangaraj M. Influence of additive manufactured stainless steel tool electrode on machinability of beta titanium alloy. Metals. 2021;11:778.

Geethapriyan T, Muthuramalingam T, Moiduddin K, Mian SM, Alkhalefah H, Umer U. Performance analysis of electrochemical micro machining of titanium (Ti-6Al-4V) alloy under different electrolytes concentrations. Metals. 2021;11:247.

Geethapriyan T, Muthuramalingam T, Kalaichelvan K. Influence of process parameters on machinability of inconel 718 by electrochemical micromachining process using TOPSIS technique. Arab J Sci Eng. 2019;44:7945–55.

Geethapriyan T, Kalaichelvan K, Muthuramalingam T, Rajadurai A. Performance analysis of process parameters on machining α-β titanium alloy in electrochemical micromachining process. Proc Inst Mech Eng B J Eng Manuf. 2018;232:1577–89.

Chung DK, Shin HS, Park MS, Kim BH, Chu CN. Recent researches in micro electrical machining. Int J Prec Eng Manuf. 2011;12:371–80.

Geethapriyan T, Muthuramalingam T, Kalaichelvan K. Multi performance optimization of electrochemical micro-machining process surface related parameters on machining inconel 718 using taguchi-grey relational analysis. Metall Ital. 2016;2016(4):13–9.

Silva AKMD, Altena HSJ, McGeogh JA. Precision ECM by process characteristics modelling. CIRP Ann. 2000;49:151–5.

Swain AK, Sundaram MM, Rajurkar KP. Use of coated microtools in advanced manufacturing: an exploratory study in electrochemical machining (ECM) context. J Manuf Process. 2012;14:150–9.

Fang X, Qu N, Li H, Zhu D. Enhancement of insulation coating durability in electrochemical drilling. Int J Adv Manuf Technol. 2013;68:2005–13.

Maniraj S, Thanigaivelan R. Effect of electrode heating on performance of electrochemical micromachining. Mater Manuf Process. 2019;34:1494–501.

Chai M, Li Z, Yan H, Sun X. Experimental investigations on aircraft blade cooling holes and CFD fluid analysis in electrochemical machining. Adv Mater Sci Eng 2019; Article ID 4219323. https://doi.org/10.1155/2019/4219323

Mouliprasanth B, Hariharan P. Measurement of performance and geometrical features in electrochemical micromachining of SS304 alloy. Exp Tech. 2020;44:259–73.

Sathish T. Experimental investigation of machined hole and optimization of machining parameters using electrochemical machining. J Mater Res Technol. 2019;8:4354–63.

Liu B, Zou H, Luo H, Yue X. Investigation on the electrochemical micromachining of micro through-hole by using micro helical electrode. Micromachines. 2020;11(2):118.

Yang Tao, Fang Xiaolong, Xiaoyun Hu, Zhengyang Xu, Zeng Yongbin. Electrochemical cutting of mortise-tenon joint structure by rotary tube electrode with helically distributed jet-flow holes. Chinese J Aeronaut. 2020. https://doi.org/10.1016/j.cja.2020.09.031.

Chavez KL, Hess DW. A novel method of etching copper oxide using acetic acid. J Electroche Soc. 2001;148:G640–3.

Geethapriyan T, Kalaichelvan K, Muthuramalingam T. Influence of coated tool electrode on drilling Inconel alloy 718 in Electrochemical micro machining. Procedia CIRP. 2016;46:127–30.

Boukhouiete A, Creus J. Nickel deposits obtained by continuous and pulsed electrodeposition processes. J Mater Environ Sci. 2015;6:1840–4.

Liang A, Liu Q, Zhang B, Ni L, Zhang J. Preparation of crystalline chromium coating on Cu substrate directly by DC electrodepositing from wholly environmentally acceptable Cr(III) electrolyte. Mater Lett. 2014;119:131–4.

Liang A, Ni L, Liu Q, Zhang J. Structure characterisation and tribological properties of thick chromium coating electrodeposited from a Cr(III) electrolyte. Surf Coat Technol. 2013;218:23–9.

He XK, Zhu Q, Hou B, Li C, Jiang Y, Zhang C, Wu L. Electrodeposition of nanocrystalline chromium coatings from 1-butyl-3-methylimidazolium-hydrogen sulfate ionic liquid. Surf Coat Technol. 2015;262:148–53.

Zhan S, Zhao Y. Plasma-assisted electrochemical machining of microtools and microstructures. Int J Mach Tool Manuf. 2020;156:103596. https://doi.org/10.1016/j.ijmachtools.2020.103596.

Chen X, Ye Z, Li G, Saxena KK, Zhang C, Zhang Y. Electrochemical milling of deep-narrow slots with a pulsating electrolyte flow field. CIRP J Manuf Sci Tech. 2022;39:244–60. https://doi.org/10.1016/j.cirpj.2022.09.004.

Zhang C, Yao J, Zhang C, Chen X, Liu J, Zhang Y. Electrochemical milling of narrow grooves with high aspect ratio using a tube electrode. J Mater Process Technol. 2020;282:116695. https://doi.org/10.1016/j.jmatprotec.2020.116695.

Mi D, Natsu W. Design of ECM tool electrode with controlled conductive area ratio for holes with complex internal features. Precis Eng. 2017;47:54–61.

Ernst A, Heib T, Hall T, Schmidt G, Bähre D. Simulation of the tool shape design for the electrochemical machining of jet engine vanes. Procedia CIRP. 2018;68:762–7.

Cebi A, Demirtas H, Aslan MT, Yilmaz O, Kanber B, Kaleli AR. A novel machine tool concept: Robotic electrochemical machining. Procedia Manuf. 2021;54:203–8.

Saxena KK, Qian J, Reynaerts D. Development and investigations on a hybrid tooling concept for coaxial and concurrent application of electrochemical and laser micromachining processes. Precis Eng. 2020;65:171–84.

Han W, Kunieda M. Research of micro EDM/ECM method in same electrolyte with running wire tool electrode. Precis Eng. 2021;70:1–14.

Zhu D, Wang K, Yang JM. Design of electrode profile in electrochemical manufacturing process. CIRP Ann Manuf Technol. 2003;52:169–72.

Park BJ, Kim BH, Chu CN. The effects of tool electrode size on characteristics of micro electrochemical machining. CIRP Ann Manuf Technol. 2006;55:197–200.

Reddy MMK. Influence of pulse period and duty ratio on electrochemical micromachining (EMM) characteristic. Int J Mech Eng Appl. 2013;1:78–86.

Mithu MAH, Fantoni G, Ciampi J. The effect of high frequency and duty cycle in electrochemical microdrilling. Int J Adv Manuf Technol. 2011;55:921–33.

Wu G, Zhang Z, Zhang W, Tang X. High frequency group pulse electrochemical machining. Front Mech Eng China. 2007;2:293–6.

Fan ZW, Hourng LW, Lin MY. Experimental investigation on the influence of electrochemical micro-drilling by short pulsed voltage. Int J Adv Manuf Technol. 2012;61:957–66.

Zhang Z, Zhu D, Qu N, Wang M. Theoretical and experimental investigation on electrochemical micromachining. Microsyst Technol. 2007;13:607–12.

Munda J, Bhattacharyya B. Investigation into electrochemical micromachining (EMM) through response surface methodology based approach. Int J Mech Eng Appl. 2008;35:821–32.

Shin HS, Kim BH, Chu CN. Analysis of the side gap resulting from micro electrochemical machining with a tungsten wire and ultrashort voltage pulses. J Micromech Microeng. 2008;18:1–5.

Bilgi DS, Jain VK, Shekhar R, Kulkarni AV. Hole quality and interelectrode gap dynamics during pulse current electrochemical deep hole drilling. Int J Adv Manuf Technol. 2007;34:79–95.

Wang JJJ, Chung CK, Wu BH, Liao YY. Fabrication of wedge-shape tool via electrochemical micromachining with diamond-like carbon coating. J Mater Process Technol. 2007;187–188:264–9.

Jain VK, Kalia S, Sidpara A, Kulkarni VN. Fabrication of micro-features and micro-tools using electrochemical micromachining. Int J Adv Manuf Technol. 2012;61:1175–83.

Dharmalingam S, Marimuthu P, Raja K. Machinability study on Al-10% TiC composites and optimum setting of drilling parameters in electrochemical micromachining machining using grey relational analysis. Lat Amer Appl Res. 2014;44:331–8.

Liu Y, Zhu D, Zeng Y, Yu H. Development of microelectrodes for electrochemical micromachining. Int J Adv Manuf Technol. 2011;55:195–203.

Wang MH, Zhu D. Fabrication of multiple electrodes and their application for micro-holes array in ECM. Int J Adv Manuf Technol. 2009;41:42–7.

Thanigaivelan R, Arunachalam R. Optimization of process parameters on machining rate and overcut in electrochemical micromachining using grey relational analysis. J Sci Ind Res. 2013;72:36–42.

Chen X, Zhu J, Xu Z, Su G. Modeling and experimental research on the evolution process of micro through-slit array generated with masked jet electrochemical machining. J Mater Process Technol. 2021;298:117304. https://doi.org/10.1016/j.jmatprotec.2021.117304.

Mahata S, Kunar S, Bhattacharyya B. Micro dimple array fabrication by through mask electrochemical micromachining utilizing low-aspect ratio mask. J Electrochem Soc. 2018;165(3):E129–37. https://doi.org/10.1149/2.0521803jes.

Bhattacharyya B, Malapati M, Munda J. Experimental study on electrochemical micromachining. J Mater Process Technol. 2005;169:485–92.

Bhattacharyya B, Munda J, Malapati M. Advancement in electrochemical micro-machining. Int J Mach Tool Manuf. 2004;44:1577–89.

Bahre D, Rebschlager A, Weber O, Steuer P. Reproducible, fast and adjustable surface roughening of stainless steel using pulse electrochemical machining. Procedia CIRP. 2013;6:384–9.

Thanigaivelan R, Arunachalam RM, Drukpa P. Drilling of micro-holes on copper using electrochemical micromachining. Int J Mach Tool Manuf. 2012;61:1185–90.

Thanigaivelan R, Arunachalam RM. Experimental study on the influence of tool electrode tip shape on electrochemical micromachining of 304 stainless steel. Mater Manuf Process. 2010;25:1181–5.

Uttarwar SS, Chopde IK. A study of influence of electrochemical process parameters on the material removal rate and surface roughness of SS AISI 304. Int J Comp Eng Res. 2013;3:189–97.

Chavoshi SZ. Analysis and predictive modelling of performance parameters in electrochemical drilling process. Int J Adv Manuf Technol. 2011;53:1081–101.

Shather SK, Abed SA, Ahmed BA. Enhancement of metal removal rate (MRR) and surface finish in electrochemical machining. Iraq J Mech Mater Eng. 2013;13:93–105.

Aherwar A, Pandey R. Experimental analysis on MRR for brass CZ131 in electrochemical machining. Emer Vis Mech E. 2013;13:278–83.

Senthilkumar C, Ganesan G, Kathikeyan R. Influence of input parameters on characteristics of electrochemical machining process. Int J Appl Sci Eng. 2013;11:13–24.

Klocke F, Zeis M, Klink A, Veselovac D. Experimental research on the electrochemical machining of modern titanium-and nickel-based alloys for aero engine components. Procedia CIRP. 2013;6:368–72.

Surekar SH, Bhatwadekar SG, Bilgi DS. Analysis of electrochemical machining process parameters affecting material removal rate of hastelloy C276. Int J Adv Res Eng Technol. 2014;5:18–23.

Burger M, Koll L, Werner EA, Platz A. Electrochemical machining characteristics and resulting surface quality of the nickel-base single-crystalline material LEK94. J Manuf Process. 2012;14:62–70.

Lee ES, Shin TH, Kim BK, Baek SY. Investigation of short pulse electrochemical machining for groove process on Ni-Ti shape memory alloy. Int J Prec Eng Manuf. 2010;11:113–8.

Mukherjee SK, Kumar S, Srivastava PK, Kumar A. Effect of valency on material removal rate in electrochemical machining of aluminium. J Mater Process Technol. 2008;202:398–401.

Ajeel SA, Hussein BAA, Baker YM. Electrochemical measurements of anodizing stainless steel type AISI 304. Int J Mech Eng Technol. 2013;4:63–74.

Dhobe SD, Doloi B, Bhattacharyya B. Surface characteristics of ECMed titanium work samples for biomedical applications. Int J Adv Manuf Technol. 2013;55:177–88.

Wang X, Qu N. Surface flattening of directed energy deposited parts through jet electrochemical machining. J Electrochem Soc. 2021;168: 123507.

Guo P, Lin X, Li J, Zhang Y, Song M, Huang W. Electrochemical behavior of Inconel 718 fabricated by laser solid forming on different sections. Corros Sci. 2018;132:79.

Guo P, Lin X, Xu J, Li J, Liu J, Huang W. Electrochemical removal of different phases from laser solid formed inconel 718. J Electrochem Soc. 2017;164:E151.

Zhang Y, Lin X, Yu J, Guo P, Li J, Qin T, Liu J, Huang W. Electrochemical dissolution behavior of heat treated laser solid formed Inconel718. Corros Sci. 2020;173: 108750.

Munda J, Malapati M, Bhattacharyya B. Control of micro-spark and stray-current effect during EMM process. J Mater Process Technol. 2007;194:151–8.

Babar PD, Jadhav BR. Experimental study on parameteric optimization of titanium based alloy (Ti-6Al-4V) in electrochemical machining process. Int J Inn Eng Technol. 2013;2:171–5.

Yong L, Yunfei Z, Guang Y, Liangqiang P. Localized electrochemical micromachining with gap control. Sens Actuator A Phys. 2013;108:144–8.

Kozak J, Rajurkar KP, Makkar Y. Selected problems of micro-electrochemical machining. J Mater Process Technol. 2004;149:426–31.

Zeng Y, Ji H, Fang X, Wang Y, Qu N. Analysis and reduction of stray-current attack in reciprocated travelling wire electrochemical machining. Adv Mech Eng. 2014;6(505932):1–11.

Tang L, Li B, Yang S, Duan Q, Kang B. The effect of electrolyte current density on the electrochemical machining S-03 material. Int J Adv Manuf Technol. 2014;71:1825–33.

Fan ZW, Hourng LW. Electrochemical micro-drilling of deep holes by rotational cathode tools. Int J Adv Manuf Technol. 2011;52:555–63.

Weibhaar K, Weinmann M, Jung A, Weber O, Natter H. Replication of microstructured tools for electrochemical machining applications. Int J Adv Manuf Technol. 2016;82:197–209.

Mithu MAH, Fantoni G, Ciampi J, Santochi M. On how tool geometry, applied frequency and machining parameters influence electrochemical microdrilling. CIRP J Manuf Sci Technol. 2012;5:202–13.

Lee ES, Baek SY, Cho CR. A study of the characteristics for electrochemical micromachining with ultrashort voltage pulses. Int J Adv Manuf Technol. 2007;31:762–9.

Qu NS, Fang XL, Zhang YD, Zhu D. Enhancement of surface roughness in electrochemical machining of Ti6Al4V by pulsating electrolyte. Int J Adv Manuf Technol. 2013;69:2703–9.

Patil P, Jadhav VS. Evaluation of material removal rate using circular-shaped tube electrode in electrochemical machining. Int J Eng Tech Res. 2013;1:30–5.

Guodong Liu, Hao Tong, Yong Li, Qifeng Tan, Yulan Zhu, Passivation behavior of S136H steel in neutral electrolytes composed of NaClO3 and NaNO3 and its influence on micro electrochemical machining performance. Mater Today Commun 2021;29: 102762, ISSN 2352–4928, https://doi.org/10.1016/j.mtcomm.2021.102762.

Lohrengel MM, Rosenkranz CHR. Microelectrochemical surface and product investigations during electrochemical machining (ECM) in NaNO3Cor. Sci. 2005;47:785–94.

Wang D, Zhu Z, Bao J, Zhu D. Reduction of stray corrosion by using iron coating in NaNO3 solution during electrochemical machining. Int J Adv Manuf Technol. 2015;76:1365–70.

Schubert N, Schneider M, Michealis A. The mechanism of anodic dissolution of cobalt in neutral and alkaline electrolyte at high current density. Electrochi Act. 2013;113:748–54.

Tang L, Yang S. Experimental investigation on the electrochemical machining of 00Cr12Ni9Mo4Cu2 material and multi-objective parameters optimization. Int J Adv Manuf Technol. 2013;67:2909–16.

Muthuramalingam T, Ramamurthy A, Moiduddin K, Alkindi M, Ramalingam S, Alghamdi O. Enhancing the surface quality of micro titanium alloy specimen in WEDM process by adopting TGRA-based optimization. Materials. 2020;13:1440.

Kozak J, Zybura-Skrabalak M. Some problems of surface roughness in electrochemical machining (ECM). Procedia CIRP. 2016;42:101–6.

Mayank G, Kunieda M. Two- phase simulation of electrochemical machining Int. J Electr Mach. 2017;22:31–5.

Zaytsev V, Zhitnikov T. Kosarev, Formation mechanism and elimination of the workpiece surface macro-defects, aligned along the electrolyte stream at electrochemical machining. J Mater Process Technol. 2004;1–3:439–44.

Klocke F, Zeis M, Klink A. Interdisciplinary modelling of the electrochemical machining process for engine blades CIRP Ann. Manuf Technol. 2015;1:217–20.

Bruggeman D. Calculation of various physics constants in heterogenous substances I: dielectric constants and conductivity of mixed bodies from isotropic substances Ann. Phys. 1935;7:636–64.

Shimasaki T, Kunieda M. Study on influences of bubbles on ECM gap phenomena using transparent electrode. CIRP Ann Manuf Technol. 2016;1:225–8.

Zhang W, Kitamura T, Koyano T, Kunieda M, Abe K. Observation of ECM gap phenomena through transparent electrode. Int J Electr Mach. 2014;19:40–4.

Guixian Liu, Yongjun Zhang, Wataru Natsu. Influence of electrolyte flow mode on characteristics of electrochemical machining with electrolyte suction tool. Int J Mach Tools Manuf 2019; 142:66–75, ISSN 0890–6955, https://doi.org/10.1016/j.ijmachtools.2019.04.010.

Xingyan Hu, Dong Zhu, Jiabao Li, Zhouzhi Gu. Flow field research on electrochemical machining with gas film insulation. J Mater Process Technol 2019;267:247–256, ISSN 0924–0136, https://doi.org/10.1016/j.jmatprotec.2018.12.019.

Li Z, Li W, Cao B. Simulation analysis of multi-physical field coupling and parameter optimization of ECM miniature bearing outer ring based on the gas-liquid two-phase turbulent flow model. Micromachines. 2022;13:902. https://doi.org/10.3390/mi13060902.

He HD, Qu NS, Zeng YB, Tong PZ. Improvement of hydrogen bubbles detaching from the tool surface in micro wire electrochemical machining by applying surface microstructures. J Electrochem Soc. 2017;9:248–59.

Fang XL, Zou XH, Chen M, Zhu D. Study on wire electrochemical machining assisted with large-amplitude vibrations of ribbed wire electrodes. CIRP Ann Manuf Technol. 2017;1:205–28.

Sawicki J, Paczkowski T. Electrochemical machining of curvilinear surfaces of revolution: analysis, modelling, and process control. Materials. 2022;15:7751. https://doi.org/10.3390/ma15217751.

Junjie Liu, Xieeryazidan Aday, Guanlin Zhou, Zhenghe Ma. Study on Marangoni- and buoyancy-driven convection in smaller Reynolds number flow field of electrochemical machining. Int Commun Heat Mass Transfer 2022;137:106289, ISSN 0735–1933, https://doi.org/10.1016/j.icheatmasstransfer.2022.106289.

Vogt H. On the supersaturation of gas in the concentration boundary layer of gas evolving electrodes. Electrochimica Acta 1980;25(5):527–31, ISSN 0013–4686, https://doi.org/10.1016/0013-4686(80)87052-6.

Steven Lubetkin. The motion of electrolytic gas bubbles near electrodes. Electrochimica Acta 2002;8(4):357–75, ISSN 0013–4686, https://doi.org/10.1016/S0013-4686(02)00682-5.

Jonathon Mitchell-Smith, Alistair Speidel, Jennifer Gaskell, Adam T. Clare, Energy distribution modulation by mechanical design for electrochemical jet processing techniques. Int J Mach Tools Manuf 2017;122: 32–46, ISSN 0890–6955, https://doi.org/10.1016/j.ijmachtools.2017.05.005.

Junzhong Zhang, Chenhao Zhao, Ningsong Qu, Zhihao Shen, Improving surface quality through macro electrochemical jet milling with novel cathode tool. J Mater Process Technol 2022;309: 117731, ISSN 0924–0136, https://doi.org/10.1016/j.jmatprotec.2022.117731.

Weidong Liu, Masanori Kunieda, Zhen Luo. Three-dimensional simulation and experimental investigation of electrolyte jet machining with the inclined nozzle. J Mater Proc Technol 2021;297:117244, ISSN 0924–0136, https://doi.org/10.1016/j.jmatprotec.2021.117244.

Mitchell-Smith J, Speidel A, Clare AT. Advancing electrochemical jet methods through manipulation of the angle of address. J Mater Proc Technol 2018;255:364–72, ISSN 0924–0136, https://doi.org/10.1016/j.jmatprotec.2017.12.026.

Muthuramalingam T. Effect of diluted dielectric medium on spark energy in green EDM process using TGRA approach. J Clean Prod. 2019;238: 117894.

Venkatesh C, Arun NM, Venkatesan R. Optimization of micro drilling parameters of B4C DRMM Al 6063 composite in µECM using taguchi coupled fuzzy logic. Procedia Eng. 2014;97:975–85.

Goswami R, Chaturvedi V, Chouhan R. Optimization of electrochemical machining process parameters using taguchi approach. Int J Eng Sci Technol. 2013;5:999–1006.

VenkataRao R, Kalyankar VD. Optimization of modern machining processes using advanced optimization techniques: a review. Int J Adv Manuf Technol. 2014;73:1159–88.

Chakradhar D, VenuGopal A. Multi-objective optimization of electrochemical machining of EN31 steel by grey relational analysis. Int J Mod Opt. 2011;1:113–7.

Das MK, Kumar K, Barman TK, Sahoo P. Optimization of surface roughness and MRR in electrochemical machining of EN31 tool steel using grey-taguchi approach. Procedia Mater Sci. 2014;6:729–40.

Bisht B, Vimal J, Chaturvedi V. Parametric optimization of electrochemical machining using signal-to-noise (S/N) ratio. Int J Mod Eng Res. 2013;3:1999–2006.

Surekar SH, Bhatwadekar SG. Optimization of parameters in electrochemical machining of Ni-base superalloy. Int J Res Aeron Mech Eng. 2016;4:72–80.

Nguyen PH, Banh LT, Mashood KA, Tran DQ, Pham V, Muthuramalingam T, Nguyen DT. Application of TGRA-based optimisation for machinability of high-chromium tool steel in the EDM process. Arabian J Sci Eng. 2020;45(7):5555–62.

Vasanth S, Muthuramalingam T. Application of laser power diode on leather cutting and optimization for better environmental quality measures. Arch Civil Mech Eng. 2021;21(2):54.

Elsheikh AH, Elaziz MA, Das SR, Muthuramalingam T, Lu S. A new optimized predictive model based on political optimizer for eco-friendly MQL-turning of AISI 4340 alloy with nano-lubricants. J Manuf Process. 2021;67:562–78.

Phan Huu N, Muthuramalingam T. Multi-criteria decision-making of vibration-aided machining for high silicon-carbon tool steel with Taguchi–TOPSIS approach. Silicon. 2021;13(8):2771–83.

Elsheikh AH, Shanmugan S, Sathyamurthy R, Thakur AK, Issa M, Panchal H, Muthuramalingam T, Kumar R, Sharifpur M. Low-cost bilayered structure for improving the performance of solar stills: performance/cost analysis and water yield prediction using machine learning. Sustain Energy Technol Assess. 2022;49:101783.

Srouhgi G, Muthuramalingam T, Moustafa EB, Elsheikh A. Investigation and TGRA based optimization of laser beam drilling process during machining of Nickel Inconel 718 alloy. J Mater Res Technol. 2022;18:720–30.

Nguyen PH, Muthuramalingam T, Pham DV, Shirguppikar S, Nguyen TN, Nguyen TC, Nguyen LT. Multi-objective optimization of micro EDM using TOPSIS method with tungsten carbide electrode. Sadhana. 2022;47:133.

Nguyen PH, Muthuramalingam T, Pham DV, Shirguppikar S, Dung IH, Thien VN, Nguyen LT. Multi-objects optimization in µ-EDM using AlCrNi-coated tungsten carbide electrode for Ti-6AL-4V. Int J Adv Manuf Technol. 2022;122:2267–76.

Liu L, Muthuramalingam T, Karmiris-Obratański P, Zhou Y, Annamalai R, Machnik R, Elsheikh A, Markopoulos AP. Optimization of wire EDM process parameters on cutting inconel 718 alloy with zinc-diffused coating brass wire electrode using Taguchi-DEAR technique. Coatings. 2022;12(11):1612.

Appalanaidu B, Dvivedi A. On the use of sacrificial layer in ECDM process for form accuracy. J Manuf Process. 2022;79:219–32. https://doi.org/10.1016/j.jmapro.2022.04.043.

Bhargav KVJ, Balaji PS, Sahu RK, Katiyar JK. Multi-response optimization and effect of tool rotation on micromachining of PMMA using an in-house developed µ-ECDM system. CIRP J Manuf Sci Technol. 2022;38:473–90. https://doi.org/10.1016/j.cirpj.2022.05.020.

Arya RK, Dvivedi A. Improving the electrochemical discharge machining (ECDM) process for deep-micro-hole drilling on glass by application of the electrolyte-air injection. Ceram Int. 2023;49(6):8916–35.

Liu S, Muthuramalingam T, Moiduddin K, Abdulrahman AM. Influence of adaptive gap control mechanism and tool electrodes on machining titanium (Ti-6Al-4V) alloy in EDM process. Materials. 2022;15(2):513.

Wang Tianbo, Liu Yong, Wang Kan. Investigation on a sustainable composite method of glass microstructures fabrication—Electrochemical discharge milling and grinding (ECDM-G). J Clean Prod. 2023;387:135788. https://doi.org/10.1016/j.jclepro.2022.135788.

Nawaz SA, Cao P, Tong H, Li Y. Micro ECDM scanning process with feedback control of flexible contact force. J Manuf Proc. 2023;94:266–77. https://doi.org/10.1016/j.jmapro.2023.03.058.

Liu S, Geethapriyan T, Muthuramalingam T, Shanmugam R, Ramoni M. Influence of heat-treated Cu-Be electrode on machining accuracy in ECMM with Monel 400 alloy. Arch Civil Mech Eng. 2022;22(4):154.

Geethapriyan T, Muthuramalingam T, Moiduddin K, Alkhalefah K, Mahalingam S, Karmiris-Obratański P. Multiobjective optimization of heat-treated copper tool electrode on EMM process using Artificial Bee Colony (ABC) algorithm. Materials. 2022;15(14):4831.

Vasanth S, Muthuramalingam T, Prakash SS, Raghav SS, Logeshwaran G. Experimental investigation of PWM laser standoff distance control for power diode based LBM. Optics Laser Technol. 2023;158:108916.

Ismail MRM, Muthuramalingam T, Karmiris-Obratański P, Papazoglou E, Karkalos N. Design of real-time extremum-seeking controller-based modelling for optimizing MRR in low power EDM. Materials. 2023;16(1):434.

Vasanth S, Muthuramalingam T, Prakash SS, Raghav SS. Investigation of SOD control on leather carbonization in diode laser cutting. Mater Manuf Proc. 2023;38(5):544–53.

Khoshaim A, Muthuramalingam T, Moustafa EB, Elsheikh A. Influences of tool electrodes on machinability of titanium α- β alloy with iso energy pulse generator in EDM process. Alexandria Eng J. 2023;63:465–74.

Muthuramalingam T, Mohan B. Influence of discharge current pulse on machinability in electrical discharge machining. Mater Manuf Processes. 2013;28(4):375–80.

Vasanth S, Muthuramalingam T, George Joseph E, Khadar SS, Saji JP, Karmiris-Obratański P. Analysis of carbon formation on machined leather specimen using FTIR technique in laser diode assisted cutting process. Materials. 2023;16(1):148.

Khalaf T, Muthuramalingam T, Moiduddin K, Swaminathan V, Mian SH, Ahmed F, Aboudaif MK. Performance evaluation of input power of diode laser on machined leather specimen in laser beam cutting process. Materials. 2023;16(6):2416.

Acknowledgements

Not applicable.

Author information

Authors and Affiliations

Contributions

All authors are involved in conducting experiments, analysis, data interpretation, finding and manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, S., Thangamani, G., Thangaraj, M. et al. Recent trends on electro chemical machining process of metallic materials: a review. Archiv.Civ.Mech.Eng 23, 158 (2023). https://doi.org/10.1007/s43452-023-00703-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-023-00703-w