Abstract

In the intelligent era, the textile technique is a high efficiency, mature and simple manufacturing solution capable of fabricating fully flexible wearable devices. However, the external circuit with its integration and comfort limitations cannot satisfy the requirements of intelligent wearable and portable devices. This study presents an industrialized production method to fabricate core–shell structure conductive yarn for direct textile use, prepared by the high-speed sirospun technique. Both integration and flexibility are significantly improved over previous works. Combining sirospun conductive yarn (SSCY) and the intarsia technique can provide the SSCY seamless and convenient embedded knitted circuit (SSCY-EKC) to form a full textile electrical element as the channel of power and signals transmission, allowing for a stable resistance change and wide strain range for meeting practical applications. SSCY based on the triboelectric nanogenerator (SSCY-TENG) can be designed as a caution carpet with attractive design and good washability for a self-powered sensor that recognizes human motions. Furthermore, intrinsic textile properties such as washability, softness, and comfort remained. With benefits such as excellent extension, fitting, and stretchability, the SSCY-EKC used herein can realize a fully flexible electrical textile with a high potential for physical detection, body gesture recognition, apparel fashion, and decoration.

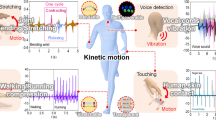

Graphical abstract

Similar content being viewed by others

References

Wei PQ, Yang X, Cao ZM, Guo XL, Jiang HL, Chen Y, Morikado M, Qiu XB, Yu D. Flexible and stretchable electronic skin with high durability and shock resistance via embedded 3D printing technology for human activity monitoring and personal healthcare. Adv Mater Technol 2019;4:1900315.

Liu Y, Pharr M, Salvatore GA. Lab-on-Skin: a review of flexible and stretchable electronics for wearable health monitoring. ACS Nano 2017;11:9614.

Chen J, Li L, Zhu Z, Luo Z, Tang W, Wang L, Li H. Bioinspired design of highly sensitive flexible tactile sensors for wearable healthcare monitoring. Mater Today Chem 2022;23:100718.

Gao YY, Li Z, Xu BG, Li MQ, Jiang CHZ, Guan XY, Yang YJ. Scalable core–spun coating yarn-based triboelectric nanogenerators with hierarchical structure for wearable energy harvesting and sensing via continuous manufacturing. Nano Energy 2022;91:106672.

Shi X, Zuo Y, Zhai P, Shen J, Yang Y, Gao Z, Liao M, Wu J, Wang J, Xu X, Tong Q, Zhang B, Wang B, Sun X, Zhang L, Pei Q, Jin D, Chen P, Peng H. Large-area display textiles integrated with functional systems. Nature 2021;591:240.

Koo JH, Kim DC, Shim HJ, Kim TH, Kim DH. Flexible and stretchable smart display: materials, fabrication, device design, and system integration. Adv Funct Mater 2018;28:1801834.

Wang Y, Ren J, Ye C, Pei Y, Ling S. Thermochromic silks for temperature management and dynamic textile displays. Nano-Micro Lett 2021;13:1.

Yang Y, Deng ZD. Stretchable sensors for environmental monitoring. Appl Phys Rev 2019;6:011309.

Wu ZX, Yang X, Wu J. Conductive hydrogel-and organohydrogel-based stretchable sensors. ACS Appl Mater Interfaces 2021;13:2128.

Zhang YZ, Lin ZK, Huang XP, You XJ, Ye JH, Wu HB. A Large-area, stretchable, textile-based tactile sensor. Adv Mater Technol 2020;5:1901060.

Wang DH, Sun JF, Xue Q, Li Q, Guo Y, Zhao YW, Chen Z, Huang ZD, Yang Q, Liang GJ. A universal method towards conductive textile for flexible batteries with superior softness. Energy Stor Mater 2021;36:272.

Dong K, Wang YC, Deng J, Dai Y, Zhang SL, Zou H, Gu B, Sun B, Wang ZL. A highly stretchable and washable all-yarn-based self-charging knitting power textile composed of fiber triboelectric nanogenerators and supercapacitors. ACS Nano 2017;11:9490.

Wen Z, Yeh MH, Guo HY, Wang J, Zi YL, Xu WD, Deng JN, Zhu L, Wang X, Hu CG. Self-powered textile for wearable electronics by hybridizing fiber-shaped nanogenerators, solar cells, and supercapacitors. Sci Adv 2016;2:e1600097.

Liao M, Ye L, Zhang Y, Chen TQ, Peng HS. The recent advance in fiber-shaped energy storage devices. Adv Electron Mater 2019;5:1800456.

Ye C, Dong S, Ren J, Ling S. Ultrastable and high-performance silk energy harvesting textiles. Nano-Micro Lett 2020;12:1.

Soroudi A, Hernández N, Wipenmyr J, Nierstrasz V. Surface modification of textile electrodes to improve electrocardiography signals in wearable smart garment. J Mater Sci Electron 2019;30:16666.

Nasiri S, Khosravani MR. Progress and challenges in fabrication of wearable sensors for health monitoring. Sens Actuators A 2020;312:112105.

Kuzubasoglu BA, Bahadir SK. Flexible temperature sensors: a review. Sens Actuators A 2020;315:112282.

García Patiño A, Khoshnam M, Menon C. Wearable device to monitor back movements using an inductive textile sensor. Sensors 2020;20:905.

Samad YA, Komatsu K, Yamashita D, Li Y, Zheng L, Alhassan SM, Nakano Y, Liao K. From sewing thread to sensor: Nylon® fiber strain and pressure sensors. Sens. Actuator B 2017;240:1083.

Shin Y-E, Lee J-E, Park Y, Hwang S-H, Chae HG, Ko H. Sewing machine stitching of polyvinylidene fluoride fibers: programmable textile patterns for wearable triboelectric sensors. J Mater Chem A 2018;6:22879.

Honda S, Zhu Q, Satoh S, Arie T, Akita S, Takei K. Textile-based flexible tactile force sensor sheet. Adv Funct Mater 2019;29:1807957.

De Rossi D. Electronic textiles: a logical step. Nat Mater 2007;6:328.

Jinno H, Fukuda K, Xu XM, Park S, Suzuki Y, Koizumi M, Yokota T, Osaka I, Takimiya K, Someya T. Stretchable and waterproof elastomer-coated organic photovoltaics for washable electronic textile applications. Nat Energy 2017;2:780.

Zhang NN, Huang F, Zhao SL, Lv XH, Zhou YH, Xiang SW, Xu SM, Li YZ, Chen GR, Tao CY. Photo-rechargeable fabrics as sustainable and robust power sources for wearable bioelectronics. Matter 2020;2:1260.

Lee J, Kwon H, Seo J, Shin S, Koo JH, Pang C, Son S, Kim JH, Jang YH, Kim DE. Conductive fiber-based ultrasensitive textile pressure sensor for wearable electronics. Adv Mater 2015;27:2433.

Shi QW, Sun JQ, Hou CY, Li YG, Zhang QH, Wang HZ. Advanced functional fiber and smart textile. Adv Fiber Mater 2019;1:3.

Weng W, Yang JJ, Zhang Y, Li YX, Yang SY, Zhu LP, Zhu MF. A route toward smart system integration: from fiber design to device construction. Adv Mater 2020;32:1902301.

Li X, Chen S, Peng Y, Zheng Z, Li J, Zhong F. Materials, preparation strategies, and wearable sensor applications of conductive fibers: a review. Sensors 2022;22:3028.

Yang M, Pan J, Xu A, Luo L, Cheng D, Cai G, Wang J, Tang B, Wang X. Conductive cotton fabrics for motion sensing and heating applications. Polymers (Basel) 2018;10:568.

Fakharuddin A, Li H, Di Giacomo F, Zhang T, Gasparini N, Elezzabi AY, Mohanty A, Ramadoss A, Ling J, Soultati A. Fiber-shaped electronic devices. Adv Energy Mater 2021;11:2101443.

Lu L-F, Cao X-J, Qi S-H. Properties investigation on electrically conductive adhesives based on acrylate resin filled with silver microsheets and silver plating carbon fibers. J Adhes Sci Technol 2017;31:1747.

Munirathinam K, Park J, Jeong Y-J, Lee D-W. Galinstan-based flexible microfluidic device for wireless human-sensor applications. Sens Actuators B 2020;315:112344.

Tran TQ, Lee JKY, Chinnappan A, Loc NH, Tran LT, Ji D, Jayathilaka W, Kumar VV, Ramakrishna S. High-performance carbon fiber/gold/copper composite wires for lightweight electrical cables. J Mater Sci Technol 2020;42:46.

Xue LL, Fan W, Yu Y, Dong K, Liu CK, Sun YL, Zhang C, Chen WC, Lei RX, Rong K. A novel strategy to fabricate core-sheath structure piezoelectric yarns for wearable energy harvesters. Adv Fiber Mater 2021;3:239.

Seyedin S, Zhang P, Naebe M, Qin S, Chen J, Wang X, Razal JM. Textile strain sensors: a review of the fabrication technologies, performance evaluation and applications. Mater Horizons 2019;6:219.

Seyedin S, Razal JM, Innis PC, Jeiranikhameneh A, Beirne S, Wallace GG. Knitted srain sensor textiles of highly conductive all-polymeric fibers. ACS Appl Mater Interfaces 2015;7:21150.

Özen Ö, Yilmaz D, Yapici K. A novel method for the production of conductive ring spun yarn. Cellulose 2022;29:4767.

Dong K, Wu Z, Deng J, Wang AC, Zou HY, Chen C, Hu D, Gu B, Sun B, Wang ZL. A stretchable yarn embedded triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and multifunctional pressure sensing. Adv Mater 2018;30:1804944.

Chen CY, Guo HY, Chen LJ, Wang YC, Pu XJ, Yu WD, Wang FM, Du ZQ, Wang ZL. Direct current fabric triboelectric nanogenerator for biomotion energy harvesting. ACS Nano 2020;14:4585.

Niu L, Miao X, Jiang G, Wan A, Li Y, Liu Q. Biomechanical energy harvest based on textiles used in self-powering clothing. J Eng Fibers Fabr 2020;15:1558925020967352.

Dong K, Peng X, An J, Wang AC, Luo JJ, Sun BZ, Wang J, Wang ZL. Shape adaptable and highly resilient 3D braided triboelectric nanogenerators as e-textiles for power and sensing. Nat Commun 2020;11:1.

Ning C, Cheng RW, Jiang Y, Sheng FF, Yi J, Shen S, Zhang Y, Peng X, Dong K, Wang ZL. Helical fiber strain sensors based on triboelectric nanogenerators for self-powered human respiratory monitoring. ACS Nano 2022;16:2811.

Niu L, Peng X, Chen LJ, Liu Q, Wang TR, Dong K, Pan H, Cong HL, Liu GL, Jiang GM. Industrial production of bionic scales knitting fabric-based triboelectric nanogenerator for outdoor rescue and human protection. Nano Energy 2022;97:107168.

Alwaidh A, Sharp M, French P. Laser processing of rigid and flexible PCBs. Opt Laser Eng 2014;58:109.

Brooke R, Wijeratne K, Hübscher K, Belaineh D, Andersson EP. Combining vapor phase polymerization and screen printing for printed electronics on flexible substrates. Adv Mater Technol 2022;7:2101665.

Song ZW, Yin JH, Wang ZH, Lu CY, Yang Z, Zhao ZH, Lin ZN, Wang JY, Wu CS, Cheng J. A flexible triboelectric tactile sensor for simultaneous material and texture recognition. Nano Energy 2022;93:106798.

de Mulatier S, Nasreldin M, Delattre R, Ramuz M, Djenizian T. Electronic circuits integration in textiles for data processing in wearable technologies. Adv Mater Technol 2018;3:1700320.

Yu A, Pu X, Wen R, Liu M, Zhou T, Zhang K, Zhang Y, Zhai J, Hu W, Wang ZL. Core–shell-yarn-based triboelectric nanogenerator textiles as power cloths. ACS Nano 2017;11:12764.

Kwak S, Kim H, Seung W, Kim J, Hinchet R, Kim S. Fully stretchable textile triboelectric nanogenerator with knitted fabric structures. ACS Nano 2017;11:10733.

Dong K, Hu YF, Yang J, Kim S-W, Hu WG, Wang ZL. Smart textile triboelectric nanogenerators: current status and perspectives. MRS Bull 2021;46:512.

Huang T, Zhang J, Yu B, Yu H, Long H, Wang H, Zhang Q, Zhu M. Fabric texture design for boosting the performance of a knitted washable textile triboelectric nanogenerator as wearable power. Nano Energy 2019;58:375.

Niu L, Miao X, Li Y, Xie X, Wen Z, Jiang G. Surface morphology analysis of knit structure-based triboelectric nanogenerator for enhancing the transfer charge. Nanoscale Res Lett 2020;15:1.

Chen C, Chen L, Wu Z, Guo H, Yu W, Du Z, Wang Z. 3D double-faced interlock fabric triboelectric nanogenerator for bio-motion energy harvesting and as self-powered stretching and 3D tactile sensors. Mater Today 2020;32:84.

Fan W, He Q, Meng K, Tan X, Zhou Z, Zhang G, Yang J, Wang Z. Machine-knitted washable sensor array textile for precise epidermal physiological signal monitoring. Sci Adv 2020;6:eaay2840.

Acknowledgements

This work was supported by the National Science Funds of China (11972172); the State Key Laboratory of New Textile Materials and Advanced Processing Technologies, No. FZ2021013; the Fundamental Research Funds for the Central Universities (JUSRP122003), the Natural Science Foundation of Jiangsu Province (BK20221094), the Fundamental Research Funds for the Central Universities (JUSRP122003).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Niu, L., Wang, J., Wang, K. et al. High-Speed Sirospun Conductive Yarn for Stretchable Embedded Knitted Circuit and Self-Powered Wearable Device. Adv. Fiber Mater. 5, 154–167 (2023). https://doi.org/10.1007/s42765-022-00203-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00203-1