Abstract

Purpose

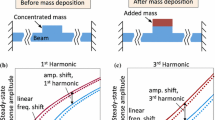

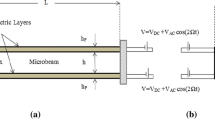

Parametric actuation in a microcantilever beam is analyzed. Here, displacement is given to the clamped end, which is determined through feedback. The sensor output has been considered with nonlinear characteristics. One of the motives of the article is to analyze the parametric excitation in a closed-loop system, where the feedback is having a feature of cubic nonlinearity. Also, the influence of noise on the response has been studied, where the power spectral density gets squeezed to certain frequencies. Another motive is to utilize the feedback based parametric excitation for a sensing application. Here, a novel scheme of mass sensing is presented for improved sensitivity, where the sensor nonlinearity and closed-loop excitation provides the scope for 3–7 times higher sensitivity.

Method

Dynamics of the cantilever beam model is studied using the multiple scales technique. For numerical analysis, discrete element method has been used. Parametric excitation based noise reduction has been demonstrated through numerical simulations, where the effect of thermal forces is considered through lumped forces.

Results

Comparing the outcome of perturbation analysis with the results of numerical simulations shows an excellent agreement. Analyzing the power spectrum of the sensor output, a novel method of mass detection has been proposed. It can provide superior performance in comparison to conventional resonant mass sensing.

Similar content being viewed by others

References

Abdolvand R, Bahreyni B, Lee JE-Y, Nabki F (2016) Micromachined resonators: a review. Micromachines 7(9):160

Rhoads JF, Shaw SW, Turner KL (2010) Nonlinear dynamics and its applications in micro-and nanoresonators. J Dyn Syst Meas Control. https://doi.org/10.1115/1.4001333

Jia Y, Seshia AA (2014) An auto-parametrically excited vibration energy harvester. Sens Actuators Phys 220:69–75

Yie Z, Miller NJ, Shaw SW, Turner KL (2012) Parametric amplification in a resonant sensing array. J Micromech Microeng 22(3):035004

Zhang W, Turner KL (2005) Application of parametric resonance amplification in a single-crystal silicon micro-oscillator based mass sensor. Sens Actuators A Phys 122(1):23–30

Prakash G, Raman A, Rhoads J, Reifenberger RG (2012) Parametric noise squeezing and parametric resonance of microcantilevers in air and liquid environments. Rev Sci Instrum 83(6):065109

Nitzan SH, Zega V, Li M, Ahn CH, Corigliano A, Kenny TW, Horsley DA (2015) Self-induced parametric amplification arising from nonlinear elastic coupling in a micromechanical resonating disk gyroscope. Sci Rep 5:9036

Mahboob I, Yamaguchi H (2008) Bit storage and bit flip operations in an electromechanical oscillator. Nat Nanotechnol 3(5):275–279

Ramini A, Alcheikh N, Ilyas S, Younis MI (2016) Efficient primary and parametric resonance excitation of bistable resonators. AIP Adv 6(9):095307

Rhoads JF, Kumar V, Shaw SW, Turner KL (2013) The non-linear dynamics of electromagnetically actuated microbeam resonators with purely parametric excitations. Int J Non-Linear Mech 55:79–89

Neumeyer S, Thomsen JJ (2012) Macroscale mechanical domain parametric amplification: superthreshold pumping and optimal excitation parameters, in EUROMECH Colloquium 532: 1st International Colloquium on Time periodic systems (TPS). Current trends in theory and application, Technische Universität Darmstadt

Villanueva LG, Karabalin RB, Matheny MH, Kenig E, Cross MC, Roukes ML (2011) A nanoscale parametric feedback oscillator. Nano Lett 11(11):5054–5059

Chakraborty G, Jani N (2021) Nonlinear dynamics of resonant microelectromechanical system (mems): a review in mechanical sciences. Springer, Berlin, pp 57–81

Hu S, Raman A (2007) Analytical formulas and scaling laws for peak interaction forces in dynamic atomic force microscopy. Appl Phys Lett 91(12):123106

Zhang W-M, Yan H, Peng Z-K, Meng G (2014) Electrostatic pull-in instability in mems/nems: a review. Sens Actuators A Phys 214:187–218

Hasan MH, Alsaleem FM, Ouakad HM (2018) Novel threshold pressure sensors based on nonlinear dynamics of mems resonators. J Micromech Microeng 28(6):065007

Turner KL, Burgner CB, Yie Z, Holtoff E (2012) Using nonlinearity to enhance micro/nanosensor performance, in SENSORS, 2012 IEEE, pp. 1–4, IEEE

Li LL, Holthoff EL, Shaw LA, Burgner CB, Turner KL (2014) Noise squeezing controlled parametric bifurcation tracking of mip-coated microbeam mems sensor for tnt explosive gas sensing. J Microelectromechanical Syst 23(5):1228–1236

Bajaj N, Sabater AB, Hickey JN, Chiu GT-C, Rhoads JFJ (2015) Design and implementation of a tunable, duffing-like electronic resonator via nonlinear feedback. J Microelectromechanical Syst 25(1):2–10

Li LL, Polunin PM, Dou S, Shoshani O, Scott Strachan B, Jensen JS, Shaw SW, Turner KL (2017) Tailoring the nonlinear response of mems resonators using shape optimization. Appl Phys Lett 110(8):081902

Ouakad HM, Younis MI (2014) On using the dynamic snap-through motion of mems initially curved microbeams for filtering applications. J Sound Vib 333(2):555–568

Moran K, Burgner C, Shaw S, Turner K (2013) A review of parametric resonance in microelectromechanical systems. Nonlinear Theory Appl IEICE 4(3):198–224

Cleland A, Roukes M (2002) Noise processes in nanomechanical resonators. J Appl Phys 92(5):2758–2769

Lübbe J, Temmen M, Rode S, Rahe P, Kühnle A, Reichling M (2013) Thermal noise limit for ultra-high vacuum noncontact atomic force microscopy. Beilstein J Nanotechnol 4(1):32–44

Mehta A, Cherian S, Hedden D, Thundat T (2001) Manipulation and controlled amplification of Brownian motion of microcantilever sensors. Appl Phys Lett 78(11):1637–1639

Rugar D, Grütter P (1991) Mechanical parametric amplification and thermomechanical noise squeezing. Phys Rev Lett 67(6):699

Moreno-Moreno M, Raman A, Gomez-Herrero J, Reifenberger R (2006) Parametric resonance based scanning probe microscopy. App Phys Lett 88(19):193108

Jani N, Chakraborty G (2020) Parametric resonance in cantilever beam with feedback-induced base excitation. J Vib Eng Technol 9(2):291–301

Thormann E, Pettersson T, Claesson PM (2009) How to measure forces with atomic force microscopy without significant influence from nonlinear optical lever sensitivity. Rev Sci Instrum 80(9):093701

Trusov AA, Shkel AM (2007) Capacitive detection in resonant mems with arbitrary amplitude of motion. J Micromec Microeng 17(8):1583

Endo D, Yabuno H, Yamamoto Y, Matsumoto S (2018) Mass sensing in a liquid environment using nonlinear self-excited coupled-microcantilevers. J Microelectromechanical Syst 27(5):774–779

Chakraborty G, Jani N (2021) Nonlinear dynamics of resonant microelectromechanical system (mems): a review. Mech Sci 1:57–81

Basso M, Paoletti P, Tiribilli B, Vassalli M (2010) Afm imaging via nonlinear control of self-driven cantilever oscillations. IEEE Trans Nanotechnol 10(3):560–565

Fukuma T, Kimura M, Kobayashi K, Matsushige K, Yamada H (2005) Development of low noise cantilever deflection sensor for multienvironment frequency-modulation atomic force microscopy. Rev Sci Instrum 76(5):053704

Delnavaz A, Mahmoodi SN, Jalili N, Mahdi Ahadian M, Zohoor H (2009) Nonlinear vibrations of microcantilevers subjected to tip-sample interactions: theory and experiment. J Appl Phys 106(11):113510

Lübbe J, Temmen M, Rahe P, Kühnle A, Reichling M (2013) Determining cantilever stiffness from thermal noise. Beilstein J Nanotechnol 4(1):227–233

Schmid S, Villanueva LG, Roukes ML (2016) Fundamentals of nanomechanical resonators, vol 49. Springer, Berlin

Ekinci K, Yang Y, Roukes M (2004) Ultimate limits to inertial mass sensing based upon nanoelectromechanical systems. J Appl Phys 95(5):2682–2689

Nayfeh AH, Pai PF (2008) Linear and nonlinear structural mechanics. Wiley, Hoboken

Agrawal AK, Chakraborty G (2020) Dynamics of a cracked cantilever beam subjected to a moving point force using discrete element method. J Vib Eng Technol 24:1–13

Neves A, Simoes F, Da Costa AP, Discrete mass and stiffness models (2016) Vibrations of cracked beams. Comput Struct 168:68–77

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

A Appendix

A Appendix

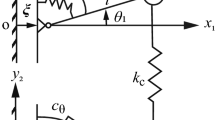

For the numerical study of the considered cantilever beam model, DEM is chosen for which a schematic diagram is presented in Fig. 3a. The relation between rotation angle (\(\theta\)) and transverse displacement(y) of the block is shown in the Fig. 3b. The first block of discretized system is considered to have zero rotation angle to realize the clamped boundary condition. For two rigid masses in the sequence, free body diagrams are shown in Fig. 3c. The equation of motion for the ith block can be written using Newtonian laws.

Similarly, for the Nth block,

For the discrete element model, different parameters can be calculated.

In the similar way for the Nth block,

Here, \(l_i\), \(m_i\), and \(J_i\) are the length, mass, and mass moment of inertia of ith the elements, respectively. From the governing equation in the nondimensionalized form (7), \(\rho A = 1\) and \(EI=C_0\). Value of \(C_0\) is taken as, \(C_0= 1.8751^{-4}\). That simplifies the nondimensionalized model with the natural frequency, \(\omega _1=1\). For a detailed study on discrete element method, one can refer to [41]. For the discretized model, the damping force is assumed lumped, acting on each block. For ith block, it can be written as

where the damping coefficient is given as,

Equivalent stiffness of torsional springs can be given as

In the considered cantilever beam model, clamped end is given transverse displacement. To realize that, rotation of the first block is restricted (\(\theta _1=0\)) and \(y_1\) will be equivalent to the given displacement. One can get the expression for \(y-\theta\) relation as

Using the above expression, following relation between \({\mathop {Y}\limits _{\thicksim }}\) and \(\Theta\) can be obtained.

That can be also written as

\({\mathop {a}\limits _{\thicksim }}_{1}\), vectors of transverse displacement \({\mathop {Y}\limits _{\thicksim }}\) and rotation of blocks \({\mathop {\Theta }\limits _{\thicksim }}\), vectors for transverse forces \({\mathop {S}\limits _{\thicksim }}\) and moments acting on blocks \({\mathop {M}\limits _{\thicksim }}\) are given as

Here, matrices are marked using bold letters, and vectors are represented by letters with tilde symbols. Matrices representing mass \(\varvec{m}\), damping coefficient \(\varvec{C_d}\), length \(\varvec{L}\), mass moment of inertia \(\varvec{J}\) of the blocks are diagonal. Stiffness matrix \(\varvec{K}\), whose elements give the torsional stiffness of the spring is also diagonal.

Assembling the equation of motion for all the blocks, using (31) and (32), one can get the following sets of equations.

Matrices, \(\varvec{A}\) and \(\varvec{B}\) have the form like,

Moments acting on the rigid blocks and their rotations are related as,

writing it in the vector form

Substituting the above expression for \({\mathop {M}\limits _{\thicksim }}\), equation of moment balance (35)b, can be written as,

Using the expression for \({\mathop {\Theta }\limits _{\thicksim }}\) and Eqs (36)b, (36)a can be written in following format so that, \({\mathop {Y}\limits _{\thicksim }}\) will only be the dependent variable.

Coefficients of the system of eq, (37) are,

(37) can be further simplified as,

Where, \(\varvec{\alpha }=(\varvec{\beta _{1}}-\varvec{A}^{-1} \varvec{m})^{-1}\).

To study the effect of thermal noise, random forces (having the white noise characteristics) are considered acting on each block of the discretized system, and the resulting system of equation of motion is shown below.

Sensor noise is considered as a white noise added to the sensor output. The resulting sensor output will be further used for the calculation of the base displacement.

The given base displacement \(y_1\) is calculated as,

Here, \({\mathop {F}\limits _{\thicksim }}_{th}\) is the random force vector, and \(n_{d}\) is the detection noise present in the sensor output.

Rights and permissions

About this article

Cite this article

Jani, N., Chakraborty, G. Feedback Based Parametric Actuation with Sensor Nonlinearity and Mass Sensing. J. Vib. Eng. Technol. 9, 1619–1634 (2021). https://doi.org/10.1007/s42417-021-00317-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42417-021-00317-7