Abstract

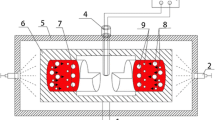

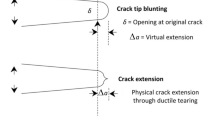

The 42 kg industrial H13 castings were prepared by different super-gravity fields with multi-rotation speeds, and the distribution of oxide inclusions in the castings was studied. In addition, the inward movement Reynolds number and inward movement time of oxide inclusions as well as the solidification time of molten steel at different positions in the castings were calculated to clarify the removal mechanism of oxide inclusions in super-gravity field. The results show that the large size (i.e., greater than 10 μm) oxide inclusions are mainly concentrated in the inner and outer parts of the super-gravity castings with constant rotation speed (500 r min−1) and five-stage rotation speeds (500, 600, 750, 850, and 950 r min−1), respectively, while there are no large oxide inclusions in the super-gravity castings with three-stage rotation speeds (500, 600, and 750 r min−1). Although an increase in the particle size of inclusion and the rotation speed in super-gravity field is conducive to the increase in the inward movement Reynolds number of oxide inclusions and reduction in the inward movement time of oxide inclusions, it will reduce the local solidification time of molten steel. In the range of the rotation speed studied, the super-gravity field with three-stage rotation speeds has the best effect on the removal of inclusions in H13 molten steel.

Similar content being viewed by others

References

J. Zhu, Z.H. Zhang, J.X. Xie, Mater. Sci. Eng. A 752 (2019) 101–114.

C. Meng, H. Zhou, H.F. Zhang, X. Tong, D.L. Cong, C.W. Wang, L.Q. Ren, Mater. Des. 51 (2013) 886–893.

C.B. Shi, ISIJ Int. 60 (2020) 1083–1096.

C.B. Shi, X.C. Chen, H.J. Guo, Z.J. Zhu, H. Ren, Steel Res. Int. 83 (2012) 472–486.

C.B. Shi, J.S. Wang, J. Li, J.W. Cho, J. Iron Steel Res. Int. 28 (2021) 1483–1503.

K.Y. Miao, M. Nabeel, N. Dogan, S. Sun, Metall. Mater. Trans. B 52 (2021) 3151–3166.

L.T. Wang, Q.Y. Zhang, S.H. Peng, Z.B. Li, ISIJ Int. 45 (2005) 331–337.

Z. Taslicukur, C. Balaban, N. Kuskonmaz, J. Eur. Ceram. Soc. 27 (2007) 637–640.

L. Zhang, S. Taniguchi, Int. Mater. Rev. 45 (2000) 59–82.

Y. Miki, H. Kitaoka, T. Sakuraya, T. Fujii, ISIJ Int. 32 (1992) 142–149.

Y. Miki, S. Ogura, T. Fujii, Kawasaki Steel Tech. Rep. (1996) No. 35, 67–73.

Y. Kusano, Y. Kawauchi, M. Wajima, K. Sugawara, M. Yoshida, H. Hayashi, ISIJ Int. 36 (1996) S77–S80.

X.F Zheng, P.C Hayes, H.G. Lee, ISIJ Int. 37 (1997) 1091–1097.

A. Weidner, D. Krewerth, B. Witschel, M. Emmel, A. Schmidt, J. Gleinig, O. Volkova, C.G. Aneziris, H. Biermann, Steel Res. Int. 87 (2016) 1038–1053.

A. Das, A. Bhowal, S. Datta, Ind. Eng. Chem. Res. 47 (2008) 4230–4235.

C.C. Lin, K.S. Chien, Separ. Purif. Technol. 63 (2008) 138–144.

Y.S. Chen, F.Y. Lin, C.C. Lin, C.Y.D. Tai, H.S. Liu, Ind. Eng. Chem. Res. 45 (2006) 6846–6853.

T. Liu, Z.C. Guo, Z. Wang, M.Y. Wang, Appl. Surf. Sci. 256 (2010) 6634–6640.

M.Y. Wang, Z. Wang, Z.C. Guo, Z.J. Li, Int. J. Hydrogen Energy 36 (2011) 3305–3312.

C. Li, J.T. Gao, Z.C. Guo, Metall. Mater. Trans. B 47 (2016) 1516–1519.

L.X. Zhao, Z.C. Guo, Z. Wang, M.Y. Wang, Metall. Mater. Trans. B 41 (2010) 505–508.

G.Y. Song, B. Song, Y.H. Yang, Z.B. Yang, W.B. Xin, Metall. Mater. Trans. B 46 (2015) 2190–2197.

C. Li, J.T. Gao, Z. Wang, Z.C. Guo, Metall. Mater. Trans. B 48 (2017) 900–907.

G.Y. Song, B. Song, Z.B. Yang, Y.H. Yang, J. Zhang, Metall. Mater. Trans. B 47 (2016) 3435–3445.

Y. Li, J.T. Gao, Z.L. Huang, Z.C. Guo, Ceram. Int. 45 (2019) 10961–10968.

C. Li, J.T. Gao, Z. Wang, H.R. Ren, Z.C. Guo, ISIJ Int. 57 (2017) 767–769.

U.D. Salgado, C. Weiß, S.K. Michelic, C. Bernhard, Metall. Mater. Trans. B 49 (2018) 1632–1643.

X.C. Huang, B.K. Li, Z.Q. Liu, X. Yang, F. Tsukihashi, Int. J. Heat Mass Transfer 135 (2019) 1300–1311.

M.Y. Zhu, W.T. Lou, W.L. Wang, Acta Metall. Sin. 54 (2018) 131–150.

X.C. Chen, Development of a new process of induction electroslag centrifugal casting and its finite element simulation, University of Science and Technology Beijing, Beijing, China, 2001.

D.G. Zhao, M. Gao, X. Li, S.H. Wang, J. Iron Steel Res. 29 (2017) 32–38.

W. Liu, S.F. Yang, J.S. Li, F. Wang, H.B. Yang, J. Iron Steel Res. Int. 26 (2019) 1147–1153.

X.H. Wang, Ironmaking and steel metallurgy — steelmaking, Higher Education Press, Beijing, China, 2007.

C. Li, Fundamental research on treatment of molten steel and steelmaking slag with super-gravity, University of Science and Technology Beijing, Beijing, China 2017.

J.M. Du, Q.Z. Shen, Metallurgical transmission principle, Metallurgical Industry Press, Beijing, China, 2011.

A. Kroupa, J. Havránková, M. Svoboda, M. Coufalová, J. Vřešt'ál, J. Phase Equilib. 22 (2001) 312.

M.T. Mao, Investigation of precipitation and elimination of primary carbide in H13 steel, University of Science and Technology Beijing, Beijing, China, 2017.

S.Y. Li, S.Y. Qin, X.J. Xi, G.Y. Sun, W.S. Yang, J. Guo, H.J. Guo, Metals 10 (2020) 1428.

Acknowledgements

This work was financially supported by China Postdoctoral Fund (No. 2021M700394) and Key R&D Plan of Shandong Province in 2021 (No. 2021CXGC010209). The authors thank the Beijing Key Laboratory of Special Melting and Preparation of High-end Metal Materials for its support. The authors wish to thank the timely help given by Li-hui Han in University of Science and Technology Beijing.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, Sy., Xi, Xj., Zhao, Xm. et al. Distribution of oxide inclusions in H13 castings under super-gravity field with multi-stage rotation speeds. J. Iron Steel Res. Int. 31, 121–133 (2024). https://doi.org/10.1007/s42243-022-00823-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00823-2