Abstract

Inspired by the self-healing function of biological organisms, Bionic Laser Alloying (BLA) process was adopted to fabricate the bionic self-healing Thermal Barrier Coatings (TBCs). The BLA with different fractions of TiAl3 self-healing agent and Ceria and Yttria-Stabilized Zirconia (CYSZ) on the plasma-sprayed 7YSZ TBCs was carried out by a pulsed Nd: YAG laser. The effect of TiAl3 content on the microstructure, phase composition, and thermal shock behaviors of the bionic self-healing TBCs were investigated. Results indicated that the bionic self-healing TBCs had better thermal shock resistance than that of the as-sprayed TBCs. The thermal shock resistance increased first and then decreased with increasing TiAl3 fraction. The thermal shock resistance of the bionic self-healing TBCs with 15% TiAl3 is triple that of the as-sprayed TBCs. On one hand, the columnar crystals and vertical cracks could improve strain compatibility of TBCs during the thermal shock process; on the other hand, the TiAl3 as a self-healing agent reacted with oxygen in air at high temperature to seal the microcracks, thereby delaying the crack connection.

Similar content being viewed by others

References

Tejero-Martin, D., Bai, M. W., Mata, J., & Hussain, T. (2021). Evolution of porosity in suspension thermal sprayed YSZ thermal barrier coatings through neutron scattering and image analysis techniques. Journal of the European Ceramic Society, 41, 6035–6048.

Kumar, N., Mahade, S., Ganvir, A., & Joshi, S. (2021). Understanding the influence of microstructure on hot corrosion and erosion behavior of suspension plasma sprayed thermal barrier coatings. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2021.127306

Reghu, V. R., Basha, A., Lobo, K., Shivakumar, S., Tilleti, P., Shankar, V., & Ramaswamy, P. (2019). Investigation on thermal barrier effects of 8YPSZ coatings on Al-Si alloy and validation through simulation. Materials Today-Proceedings, 19, 630–636.

Morelli, S., Testa, V., Bolelli, G., Ligabue, O., Molinari, E., Antolotti, N., & Lusvarghi, L. (2020). CMAS corrosion of YSZ thermal barrier coatings obtained by different thermal spray processes. Journal of the European Ceramic Society, 40, 4084–4100.

Shi, M. C., Xue, Z. L., Zhang, Z. Y., Ji, X. J., Byon, E. S., & Zhang, S. H. (2020). Effect of spraying powder characteristics on mechanical and thermal shock properties of plasma-sprayed YSZ thermal barrier coating. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2020.125913

Zhang, P. P., Zhang, X. F., Li, F. H., Zhang, Z. H., Wang, Y. L., Li, H., Ren, L. Q., & Liu, M. (2019). Hot corrosion behavior of YSZ thermal barrier coatings modified by laser remelting and Al deposition. Journal of Thermal Spray Technology, 28, 1225–1238.

Ghadami, F., Aghdam, A. S. R., & Ghadami, S. (2020). Preparation, characterization and oxidation behavior of CeO2 -gradient NiCrAlY coatings applied by HVOF thermal spraying process. Ceramics International, 46, 20500–20509.

Slamecka, K., Jech, D., Klakurkova, L., Tkachenko, S., Remesova, M., Gejdos, P., & Celko, L. (2020). Thermal cycling damage in pre-oxidized plasma-sprayed MCrAlY plus YSZ thermal barrier coatings: Phenomenon of multiple parallel delamination of the TGO layer. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2019.125328

Chen, Y., Zhao, X. F., & Xiao, P. (2020). Effect of surface curvature on oxidation of a MCrAlY coating. Corrosion Science. https://doi.org/10.1016/j.corsci.2019.108256

Chen, Y., Zhao, X. F., & Xiao, P. (2018). Effect of microstructure on early oxidation of MCrAlY coatings. Acta Materialia, 159, 150–162.

Soleimanipour, Z., Baghshahi, S., & Shoja-razavi, R. (2017). Improving the thermal shock resistance of thermal barrier coatings through formation of an in situ YSZ/Al2O3 composite via laser cladding. Journal of Materials Engineering and Performance, 26, 1890–1899.

Huang, Y. L., Shen, Y. T., Zeng, Y., Song, X. M., Lin, C. C., Zhang, J. M., & Guo, X. (2021). EBSD analysis of microstructure changes in YSZ coatings during thermal cycling. Ceramics International, 47, 5559–5569.

Nozahic, F., Monceau, D., & Estournes, C. (2016). Thermal cycling and reactivity of a MoSi2/ZrO2 composite designed for self-healing thermal barrier coatings. Materials and Design, 94, 444–448.

Ray, A. K., & Steinbrech, R. W. (1999). Crack propagation studies of thermal barrier coatings under bending. Journal of the European Ceramic Society, 19, 2097–2109.

Sun, J. Y., Tong, J., & Ma, Y. H. (2008). Nanomechanical behaviours of cuticle of three kinds of beetle. Journal of Bionic Engineering, 5, 152–157.

Lomakin, J., Arakane, Y., Kramer, K. J., Beeman, R. W., Kanost, M. R., & Gehrke, S. H. (2010). Mechanical properties of elytra from Tribolium castaneum wild-type and body color mutant strains. Journal of Insect Physiology, 56, 1901–1906.

Faisal, T. R., Abad, E. M. K., Hristozov, N., & Pasini, D. (2010). The impact of tissue morphology, cross-section and turgor pressure on the mechanical properties of the leaf petiole in plants. Journal of Bionic Engineering, 7, S11–S23.

Wang, X. S., Li, Y., & Shi, Y. F. (2008). Effects of sandwich microstructures on mechanical behaviors of dragonfly wing vein. Composites Science and Technology, 68, 186–192.

Song, J. R., Fan, C. C., Ma, H. S., Liang, L. H., & Wei, Y. G. (2018). Crack deflection occurs by constrained microcracking in nacre. Acta Mechanica Sinica, 34, 143–150.

Zhang, Z. H., Zhang, L., Yu, Z. L., Liu, J. J., Li, X. J., & Liang, Y. H. (2018). In-situ mechanical test of dragonfly wing veins and their crack arrest behavior. Micron, 110, 67–72.

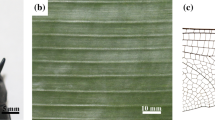

Wu, L. S., Wang, T., Hu, Y., Liu, J. M., & Song, M. J. (2020). A method for improving the crack resistance of aluminum alloy aircraft skin inspired by plant leaf. Theoretical and Applied Fracture Mechanics. https://doi.org/10.1016/j.tafmec.2019.102444

Zhang, P. P., Li, F. H., Zhang, X. F., Zhang, Z. H., Zhou, F. F., Ren, L. Q., & Liu, M. (2019). Thermal shock resistance of thermal barrier coatings with different surface shapes modified by laser remelting. Journal of Thermal Spray Technology, 28, 417–432.

Zhang, P. P., Sun, L., Zhang, X. F., Wang, Y. L., Zhang, Q. L., Yao, J. H., & Chang, F. (2021). Thermal cycling behavior of selective laser-remelted thermal barrier coatings with different laser dot distances. Journal of Thermal Spray Technology, 30, 1038–1048.

Wang, Y., Park, J. P., Hong, S. H., & Lee, H. (2016). Biologically inspired materials exhibiting repeatable regeneration with self-sealing capabilities without external stimuli or catalysts. Advanced Materials, 28, 9961–9968.

Ouyang, T. Y., & Suo, J. P. (2021). TiC-self-healing thermal barrier coating structures and oxidation resistance. Surface and Coatings Technology. https://doi.org/10.1016/j.surfcoat.2021.127065

Ouyang, T. Y., Wu, J. Y., Yasir, M., Zhou, T., Fang, X. W., Wang, Y., Liu, D. W., & Suo, J. P. (2016). Effect of TiC self-healing coatings on the cyclic oxidation resistance and lifetime of thermal barrier coatings. Journal of Alloys and Compounds, 656, 992–1003.

Portilla-Zea, K., Gonzalez, M. A., Rodriguez, E., & Vasquez, G. I. (2021). Enhanced adhesion resistance of an 8YSZ thermal barrier coating trough the formation of zircon and mullite as self-healing reaction products under cyclic oxidation conditions. Materials Letters. https://doi.org/10.1016/j.matlet.2020.128697

Jiao, X. Y., Ren, X. R., Wang, X. H., Wang, S. G., Feng, P. Z., & Wang, J. Z. (2018). Porous TiAl3 intermetallics with symmetrical graded pore-structure fabricated by leaching space holder and thermal explosion process. Intermetallics, 95, 144–149.

Shen, Z. J., Zhang, Y. N., Yu, X. H. (2019) Interfacial microstructure evolution mechanism of high temperature oxidation-resistant Al-based coating on Ti alloy surface. Materials Research Express, 6, 086472. https://doi.org/10.1088/2053-1591/ab2a66

Wang, L., Zhong, X. H., Shao, F., Ni, J. X., Yang, J. S., Tao, S. Y., & Wang, Y. (2018). What is the suitable segmentation crack density for atmospheric plasma sprayed thick thermal barrier coatings with the improved thermal shock resistance? Applied Surface Science, 431, 101–111.

Zhang, P. P., Zhang, X. F., Li, F. H., Zhang, Z. H., Li, H., Wang, Y. L., Ren, L. Q., & Liu, M. (2019). Effects of selective laser modification and Al deposition on the hot corrosion resistance of ceria and yttria-stabilized zirconia thermal barrier coatings. Coatings, 9, 353.

Fan, Z. J., Wang, K. D., Dong, X., Duan, W. Q., Mei, X. S., Wang, W. J., Cui, J. L., & Lv, J. (2015). Influence of columnar grain microstructure on thermal shock resistance of laser re-melted ZrO2-7 wt.% Y2O3 coatings and their failure mechanism. Surface and Coatings Technology, 277, 188–196.

Wang, D. S., Tian, Z. J., Shen, L. D., Liu, Z. D., & Huang, Y. H. (2014). Effects of laser remelting on microstructure and solid particle erosion characteristics of ZrO2-7wt%Y2O3 thermal barrier coating prepared by plasma spraying. Ceramics International, 40, 8791–8799.

Zhang, Z. H., Zhou, H., Ren, L. Q., Tong, X., Shan, H. Y., & Li, X. Z. (2008). Surface morphology of laser tracks used for forming the non-smooth biomimetic unit of 3Cr2W8V steel under different processing parameters. Applied Surface Science, 254, 2548–2555.

Dhineshkumar, S. R., Duraiselvam, M., Natarajan, S., Panwar, S. S., Jena, T., & Khan, M. A. (2016). Enhancement of strain tolerance of functionally graded LaTi2Al9O19 thermal barrier coating through ultra-short pulse based laser texturing. Surface and Coatings Technology, 304, 263–271.

Bai, Y., Han, Z. H., Li, H. Q., Xu, C., Xu, Y. L., Wang, Z., Ding, C. H., & Yang, J. F. (2011). High performance nanostructured ZrO2 based thermal barrier coatings deposited by high efficiency supersonic plasma spraying. Applied Surface Science, 257, 7210–7216.

Lee, J. H., Tsai, P. C., & Chang, C. L. (2008). Microstructure and thermal cyclic performance of laser-glazed plasma-sprayed ceria-yttria-stabilized zirconia thermal barrier coatings. Surface and Coatings Technology, 202, 5607–5612.

Schulz, U. (2000). Phase transformation in EB-PVD yttria partially stabilized zirconia thermal barrier coatings during annealing. Journal of the American Ceramic Society, 83, 904–910.

Liang, B., Ding, C. X., Liao, H. L., & Coddet, C. (2006). Phase composition and stability of nanostructured 4.7 wt.% yttria-stabilized zirconia coatings deposited by atmospheric plasma spraying. Surface and Coatings Technology, 200, 4549–4556.

Witz, G., Shklover, V., Steurer, W., Bachegowda, S., & Bossmann, H. P. (2007). Phase evolution in yttria-stabilized zirconia thermal barrier coatings studied by rietveld refinement of X-ray powder diffraction patterns. Journal of the American Ceramic Society, 90, 2935–2940.

Smialek, J. L., & Humphrey, D. L. (1992). Oxidation-kinetics of cast TiAl3. Scripta Metallurgica et Materialia, 26, 1763–1768.

Chu, M. S., & Wu, S. K. (2005). Oxidation behavior of Ti-50Al intermetallics with thin TiAl3 film at 1000 degrees C. Oxidation of Metals, 63, 1–13.

Gauthier, V., Dettenwanger, F., Schutze, M., Shemet, V., & Quadakkers, W. J. (2003). Oxidation-resistant aluminide coatings on gamma-TiAl. Oxidation of Metals, 59, 233–255.

Wei, Z. Y., Cai, H. N., Tahir, A., Zhang, W. W., Li, X. F., Zhang, Y., Huang, Y. P., & Liu, Y. (2019). Stress states in plasma-sprayed thermal barrier coatings upon temperature cycling: Combined effects of creep, plastic deformation, and TGO growth. Ceramics International, 45, 19829–19844.

Acknowledgements

This work is supported by National Natural Science Foundation of China (Grant No. 52105311), Natural Science Foundation of Zhejiang Province (Grant No. LQ21E010002), and Fundamental Research Funds for the Provincial Universities of Zhejiang (Grant No. RF-A2020009).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, P., Guo, Y., Zhang, Z. et al. Effect of TiAl3 Content on Thermal Shock Resistance of Bionic Self-healing Thermal Barrier Coatings. J Bionic Eng 19, 126–138 (2022). https://doi.org/10.1007/s42235-021-00108-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-021-00108-6