Abstract

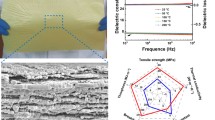

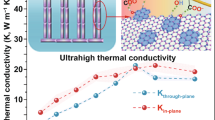

Two-dimensional (2D) boron nitride nanosheets (BNNS), with exceptional thermoconductive properties and wide band gap, hold a great promise as candidate fillers for the preparation of the functional dielectric composites. However, the unsatisfactory dispersity in solvents and poor interfacial compatibility with the polymer matrix are still a great baffle for its practical applications. In the present study, we show that non-covalent functionalization of BNNS via polyvinylpyrrolidone (PVP) is a facile approach to optimizing their surface characteristics and facilitating the preparation of hybrid composites. The PVP functionalized BNNS (BNNS@PVP) can be dispersed stably in the aqueous solution for over 2 weeks. Composite films with ultrahigh thermal conductivity (~ 14.5 W m−1 K−1) are achieved solely by mixing with BNNS@PVP and one-dimensional (1D) aramid nanofibers (ANFs). Additionally, strong interfacial interactions are constructed between BNNS@PVP and ANFs, which further enables efficient stress transfer and charge dissipation through the 1D/2D configuration, contributing to outstanding tensile strength (~ 184 MPa) and high electric breakdown strength (~ 274 kV mm−1) for composite films. All these results demonstrate that surface modification of BNNS is a powerful tool for developing functional materials with multipurpose applications, including thermal management and high-voltage insulation.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings are available from authors on request.

References

Jing X, Li Y, Zhu J, Chang L, Maganti S, Naik N, Xu BB, Murugadoss V et al (2022) Improving thermal conductivity of polyethylene/polypropylene by styrene-ethylene-propylene-styrene wrapping hexagonal boron nitride at the phase interface. Adv Compos Hybrid Mater 5:1090. https://doi.org/10.1007/s42114-022-00438-x

Yuan G, Wan T, BaQais A, Mu Y, Cui D, Amin MA, Li X, Xu BB et al (2023) Boron and fluorine Co-doped laser-induced graphene towards high-performance micro-supercapacitors. Carbon 212:118101. https://doi.org/10.1016/j.carbon.2023.118101

Fan G, Wang Z, Ren H, Liu Y, Fan R (2021) Dielectric dispersion of copper/rutile cermets: dielectric resonance, relaxation, and plasma oscillation. Scr Mater 190:1. https://doi.org/10.1016/j.scriptamat.2020.08.027

Wang T, Zhang G, Zhang B, Liu S, Li D, Liu C (2021) Oriented boron nitride nanosheet films for thermal management and electrical insulation in electrical and electronic equipment. ACS Appl Nano Mater 4:4153–4161. https://doi.org/10.1021/acsanm.1c00484

Gao Q, Pan Y, Zheng G, Liu C, Shen C, Liu X (2021) Flexible multilayered MXene/thermoplastic polyurethane films with excellent electromagnetic interference shielding, thermal conductivity, and management performances. Adv Compos Hybrid Mater 4:274–285. https://doi.org/10.1007/s42114-021-00221-4

Vu MC, Kang H, Park PJ, Choi B-G, Paik J-W, Choi W-K, Islam MA, Wang Q et al (2022) Scalable graphene fluoride sandwiched aramid nanofiber paper with superior high-temperature capacitive energy storage. Chem Eng J 444:136504–136514. https://doi.org/10.1016/j.cej.2022.136504

Wu M, Zhou Y, Zhang H, Liao W (2022) 2D boron nitride nanosheets for smart thermal management and advanced dielectrics. Adv Mater Interfaces 9(25):2200610–2200635. https://doi.org/10.1002/admi.202200610

Narendra Kumar Y, Venkateswarlu B, Ratna Raju L, Dumpala R, Ratna Sunil B (2021) Developing Zn-MgO composites for degradable implant applications by powder metallurgy route. Mater Lett 302:130433. https://doi.org/10.1016/j.matlet.2021.130433

Huang H, Chen Z, Chen X, Jin J, Huang S, Wang D, Wang L, Liu D (2022) Substrate modification for high-performance thermoelectric materials and generators based on polymer and carbon nanotube composite. Adv Mater Interfaces 9(23):2201193. https://doi.org/10.1002/admi.202201193

Pan D, Dong J, Yang G, Su F, Chang B, Liu C, Zhu Y-C, Guo Z (2021) Ice template method assists in obtaining carbonized cellulose/boron nitride aerogel with 3D spatial network structure to enhance the thermal conductivity and flame retardancy of epoxy-based composites. Adv Compos Hybrid Mater 5:58. https://doi.org/10.1007/s42114-021-00362-6

Salunke DR, Gopalan V (2021) Thermal and electrical behaviors of boron nitride/epoxy reinforced polymer matrix composite — a review. Polym Compos 42(4):1659–1669. https://doi.org/10.1002/pc.25952

Han Y, Shi X, Wang S, Ruan K, Lu C, Guo Y, Gu J (2021) Nest-like hetero-structured BNNS@SiCnws fillers and significant improvement on thermal conductivities of epoxy composites. Compos B Eng 210:108666. https://doi.org/10.1016/j.compositesb.2021.108666

Meng J, Wang D, Cheng L, Gao M, Zhang X (2019) Recent progress in synthesis, properties, and applications of hexagonal boron nitride-based heterostructures. Nanotechnology 30(7):74003–74022. https://doi.org/10.1088/1361-6528/aaf301

Bayır S, Semerci E, Erdogan Bedri T (2021) Preparation of novel thermal conductive nanocomposites by covalent bonding between hexagonal boron nitride nanosheet and well-defined polymer matrix. Compos Part A Appl Sci Manuf 146:1–8. https://doi.org/10.1016/j.compositesa.2021.106406

Wu K, Fang J, Ma J, Huang R, Chai S, Chen F, Fu Q (2017) Achieving a collapsible, strong, and highly thermally conductive film based on oriented functionalized boron nitride nanosheets and cellulose nanofiber. ACS Appl Mater Interfaces 9(35):30035–30045. https://doi.org/10.1021/acsami.7b08214

Vatanpour V, Naziri Mehrabani SA, Keskin B, Arabi N, Zeytuncu B, Koyuncu I (2021) A comprehensive review on the applications of boron nitride nanomaterials in membrane fabrication and modification. Ind Eng Chem Res 60:13391. https://doi.org/10.1021/acs.iecr.1c02102

Kim JM, Jung D-W, Kim LS, Kim M, Jeong S, Lee S, Chang S-J, Cho JY et al (2021) Continuously thermal conductive pathway of bidisperse boron nitride fillers in epoxy composite for highly efficient heat dissipation. Mater Today Commun 27:102230. https://doi.org/10.1016/j.mtcomm.2021.102230

Zhao L, Yan L, Wei C, Wang Z, Jia L, Ran Q, Huang X, Ren J (2020) Aqueous-phase exfoliation and functionalization of boron nitride nanosheets using tannic acid for thermal management applications. Ind Eng Chem Res 59:16273–16282. https://doi.org/10.1021/acs.iecr.0c02766

Hu Z, Liu Y, Lin J, Wu H, Liu B, Guo W, Lin X, Chen L et al (2022) Pyrene-functionalized alkali lignin to disperse hydroxylated boron nitride nanosheets in cellulose nanofibers for thermal management. ACS Appl Nano Mater 6(1):200–211. https://doi.org/10.1021/acsanm.2c04238

Qian X, Zhou J, Chen G (2021) Phonon-engineered extreme thermal conductivity materials. Nat Mater 20(9):1188–1202. https://doi.org/10.1038/s41563-021-00918-3

Singh V, Bougher TL, Weathers A, Cai Y, Bi K, Pettes MT, McMenamin SA, Lv W et al (2014) High thermal conductivity of chain-oriented amorphous polythiophene. Nat Nanotechnol 9:384–390. https://doi.org/10.1038/nnano.2014.44

Zeng X, Xiong Y, Fu Q, Sun R, Xu J, Xu D, Wong CP (2017) Structure-induced variation of thermal conductivity in epoxy resin fibers. Nanoscale 9:10585–10589. https://doi.org/10.1039/c7nr03717a

Jia L, Jin Y, Ren J, Zhao L, Yan D, Li Z (2021) Highly thermally conductive liquid metal-based composites with superior thermostability for thermal management. J Mater Chem C 9:2904. https://doi.org/10.1039/d0tc05493c

Zeng Z, Xu C, Ren J, Yang Z, Wu G, Wei W (2023) Significantly enhanced thermal conductivity of the aramid nanofiber composite film with GO and Ag nanoflakes for thermal management application. J Appl Phys 133:215301. https://doi.org/10.1063/5.0145436

Wu K, Wang J, Liu D, Lei C, Liu D, Lei W, Fu Q (2020) Highly thermoconductive, thermostable, and super-flexible film by engineering 1D rigid rod-like aramid nanofiber/2D boron nitride nanosheets. Adv Mater 32:e1906939. https://doi.org/10.1002/adma.201906939

Yang M, Cao KQ, Sui L, Qi Y, Zhu J, Waas A, Arruda EM, Kieffer J et al (2011) Dispersions of aramid nanofibers: a new nanoscale building block. ACS Nano 5:6945–6954. https://doi.org/10.1021/nn2014003

Zhou B, Li Q, Xu P, Feng Y, Ma J, Liu C, Shen C (2021) An asymmetric sandwich structural cellulose-based film with self-supported MXene and AgNW layers for flexible electromagnetic interference shielding and thermal management. Nanoscale 13:2378–2388. https://doi.org/10.1039/d0nr07840a

Shaybanizadeh S, Chermahini AN (2021) Fabricating boron nitride nanosheets from hexagonal BN in water solution by a combined sonication and thermal-assisted hydrolysis method. Ceram Int 47:11122–11128. https://doi.org/10.1016/j.ceramint.2020.12.236

Zhang X, Zhang J, Xia L, Li C, Wang J, Xu F, Zhang X, Wu H et al (2017) Simple and consecutive melt extrusion method to fabricate thermally conductive composites with highly oriented boron nitrides. ACS Appl Mater Interfaces 9:22977–22984. https://doi.org/10.1021/acsami.7b05866

Zheng X, Cong H, Yang T, Ji K, Wang C, Chen M (2022) High-efficiency 2D nanosheet exfoliation by a solid suspension-improving method. Nanotechnology 33(18):185602–185612. https://doi.org/10.1088/1361-6528/ac4b7c

Zhang W, Rahman MM, Ahmed F, Lopa NS, Ge C, Ryu T, Yoon S, Jin L et al (2020) A two-step approach for improved exfoliation and cutting of boron nitride into boron nitride nanodisks with covalent functionalizations. Nanotechnology 31. https://doi.org/10.1088/1361-6528/ab9a76

Oh H, Kim J (2019) Fabrication of polymethyl methacrylate composites with silanized boron nitride by in-situ polymerization for high thermal conductivity. Compos Sci Technol 172:153–162. https://doi.org/10.1016/j.compscitech.2019.01.021

Yu H, Wang B, Zhou S, Zhu M, Chen W, Chen H, Li X, Liang S et al (2021) Polyvinylpyrrolidone functionalization induces deformable structure of graphene oxide nanosheets for lung-targeting delivery. Nano Today 38:101151. https://doi.org/10.1016/j.nantod.2021.101151

Hou C, Yang W, Kimura H, Xie X, Zhang X, Sun X, Yu Z, Yang X et al (2023) Boosted lithium storage performance by local build-in electric field derived by oxygen vacancies in 3D holey N-doped carbon structure decorated with molybdenum dioxide. J Mater Sci Technol 142:185. https://doi.org/10.1016/j.jmst.2022.10.007

Xu L, Zhao X, Xu C, Kotov NA (2017) Water-rich biomimetic composites with abiotic self-organizing nanofiber network. Adv Mater 30(1):1703343. https://doi.org/10.1002/adma.201703343

Guo Y, Ruan K, Shi X, Yang X, Gu J (2020) Factors affecting thermal conductivities of the polymers and polymer composites: a review. Compos Sci Technol 193:108134. https://doi.org/10.1016/j.compscitech.2020.108134

Huang J, E S, Li J, Jia F, Ma Q, Hua L, Lu Z, (2021) Ball-milling exfoliation of hexagonal boron nitride in viscous hydroxyethyl cellulose for producing nanosheet films as thermal interface materials. ACS Appl Nano Mater 4(12):13167–13175. https://doi.org/10.1021/acsanm.1c02696

Kim D, You M, Seol JH, Ha S, Kim YA (2017) Enhanced thermal conductivity of individual polymeric nanofiber incorporated with boron nitride nanotubes. J Phys Chem C 121(12):7025–7029. https://doi.org/10.1021/acs.jpcc.7b00047

Fan L, Zhang S, Zhao G, Fu Q (2021) Constructing fibrillated skeleton with highly aligned boron nitride nanosheets confined in alumina fiber via electrospinning and sintering for thermally conductive composite. Compos Part A Appl Sci Manuf 143:106282–106292. https://doi.org/10.1016/j.compositesa.2021.106282

Shen X, Zheng Q, Kim JK (2020) Rational design of two-dimensional nanofillers for polymer nanocomposites toward multifunctional applications. Prog Mater Sci 115:100708. https://doi.org/10.1016/j.pmatsci.2020.100708

Song N, Zhang F, Cao D, Wang P, Ding P (2022) Bicontinuous laminated structure design of polypropylene/reduced graphene oxide hybrid films for thermal management. Adv Compos Hybrid Mater 5:2873. https://doi.org/10.1007/s42114-022-00470-x

Wang Z, Wu Z, AlMasoud N, Weng L, Alomar TS, El-Bahy ZM, He M, Yang C et al (2023) Effective three-dimensional thermal conductivity networks in polystyrene/multi-walled carbon nanotubes/aluminum oxide@hexagonal boron nitride composites based on synergistic effects and isolated structures. Adv Compos Hybrid Mater 6:125. https://doi.org/10.1007/s42114-023-00702-8

Nan C-W, Birringer R, Clarke DR, Gleiter H (1997) Effective thermal conductivity of particulate composites with interfacial thermal resistance. J Appl Phys 81:6692. https://doi.org/10.1063/1.365209

Wang J, Jin X, Li C, Wang W, Wu H, Guo S (2019) Graphene and graphene derivatives toughening polymers: toward high toughness and strength. Chem Eng J 370:831–854. https://doi.org/10.1016/j.cej.2019.03.229

Zhao L, Liao C, Liu Y, Huang X, Ning W, Wang Z, Jia L, Ren J (2021) A combination of aramid nanofiber and silver nanoparticle decorated boron nitride for the preparation of a composite film with superior thermally conductive performance. Compos Interfaces 29(4):447–463. https://doi.org/10.1080/09276440.2021.1950378

Huang X, Nakagawa S, Houjou H, Yoshie N (2021) Insights into the role of hydrogen bonds on the mechanical properties of polymer networks. Macromolecules 54:4070. https://doi.org/10.1021/acs.macromol.1c00120

Sakhavand N, Shahsavari R (2018) Insights on synergy of materials and structures in biomimetic platelet-matrix composites. Appl Phys Lett 112:051601. https://doi.org/10.1063/1.5017200

Zhou W, Cao G, Yuan M, Zhong S, Wang Y, Liu X, Cao D, Peng W et al (2023) Core-shell engineering of conductive fillers toward enhanced dielectric properties: a universal polarization mechanism in polymer conductor composites. Adv Mater 35:e2207829. https://doi.org/10.1002/adma.202207829

Wu Z, Wang X, Annamareddy SHK, Gao S, Xu Q, Algadi H, Sridhar D, Wasnik P et al (2023) Dielectric properties and thermal conductivity of polyvinylidene fluoride synergistically enhanced with silica@multi-walled carbon nanotubes and boron nitride. ES Mater Manuf 22:847. https://doi.org/10.30919/esmm5f847

Xie ZL, Wu K, Liu DY, Zhang Q, Fu Q (2021) One-step alkyl-modification on boron nitride nanosheets for polypropylene nanocomposites with enhanced thermal conductivity and ultra-low dielectric loss. Compos Sci Technol 208:108756. https://www.sciencedirect.com/science/article/abs/pii/S0266353821001123

Zhao L, Wei C, Ren J, Li Y, Zheng J, Jia L, Wang Z, Jia S (2022) Biomimetic nacreous composite films toward multipurpose application structured by aramid nanofibers and edge-hydroxylated boron nitride nanosheets. Ind Eng Chem Res 61(25):8881–8894. https://doi.org/10.1021/acs.iecr.2c01281

Lee H, Lee J, Joo SH, Kang SJ, Kwak SK, Yu S, Park C (2020) Dual functionalization of hexagonal boron nitride nanosheets using pyrene-tethered poly(4-vinylpyridine) for stable dispersion and facile device incorporation. ACS Appl Nano Mater 3:7633. https://doi.org/10.1021/acsanm.0c01262

Feng C-P, Bai L, Bao R-Y, Liu Z-Y, Yang M-B, Chen J, Yang W (2017) Electrically insulating POE/BN elastomeric composites with high through-plane thermal conductivity fabricated by two-roll milling and hot compression. Adv Compos Hybrid Mater 1:160. https://doi.org/10.1007/s42114-017-0013-2

Wang Y, Yang D, Hessien MM, Du K, Ibrahim MM, Su Y, Mersal GAM, Ma R et al (2022) Flexible barium titanate@polydopamine/polyvinylidene fluoride/polymethyl methacrylate nanocomposite films with high performance energy storage. Adv Compos Hybrid Mater 5:2106. https://doi.org/10.1007/s42114-022-00552-w

Funding

We appreciate the financial support from the National Natural Science Foundation of China (52107020, 52377028, 52301192, 52377026), the Key R & D project of Sichuan Province (2023YFG0236), the State Key Laboratory of Electrical Insulation and Power Equipment (EIPE23210), and the Postdoctoral Science Foundation of China (2018M643475).

Author information

Authors and Affiliations

Contributions

Junwen Ren: conceptualization, investigation, formal analysis, methodology, writing—original draft, writing—review and editing. Guoqing Jiang: data curation, investigation, methodology. Zi Wang: investigation, methodology. Qiuwanyu Qing: formal analysis. Fuli Teng and Guanglei Wu: formal analysis. Zirui Jia and Shenli Jia: formal analysis, writing—review and editing.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ren, J., Jiang, G., Wang, Z. et al. Highly thermoconductive and mechanically robust boron nitride/aramid composite dielectric films from non-covalent interfacial engineering. Adv Compos Hybrid Mater 7, 5 (2024). https://doi.org/10.1007/s42114-023-00816-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00816-z