Abstract

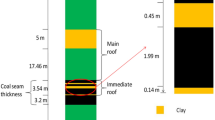

Proper investigation of the face spalling mechanism with its associated rock mechanics indicators is crucial for effective ground control in deep longwall workings, particularly under massive strata conditions comprising high strength and large thickness. This paper deals with the three-dimensional elastoplastic modeling study to understand the damage and associated spalling characteristics in a retreating longwall working. The stress–strain redistribution was simulated with progressive face retreat till the occurrence of the first weighting. The quantification of the various rock mechanics indicators viz. major principal stress, axial strain, and lateral strain were presented in the three distinct face loading conditions, namely normal, peak-stress, and weighting. The excavation damage concept was implemented to quantify the extent of EDZ (excavation damaged zone) and HDZ (highly damaged zone) at the face. The role of the massive key roof in differential loading along the length of the face was also examined. Finally, a set of design criteria for the three-dimensional assessment of the extent of face spalling was proposed integrating the results of the numerical modeling and field observations. The study revealed that the central section of the face experienced a higher intensity of damage than the gate end section when the face was exposed to extreme stress conditions. The model results indicated that 52% of the face length extending over 130 m in the central section of the 250 m long face was affected by spalling. The spalling was initiated at the middle position of the 3.5 m high face and extended to its top position affecting the 0–3 m region ahead of the face. The study also showed that the extent of spalling during the first weighting varied between 24 to 40% of the zones within the affected region. The model-observed extent of face spalling was validated against the field observation. The modeling results also agreed well with the redistribution pattern of induced stresses, differential load transfer at the face, and the mechanism of damage in the overlying strata as well as the coal face generally observed in the field. The findings of this study present a unique perspective for the rational design of face length for effective roof control in deep longwall workings.

Article Highlights

-

A numerical modeling approach was developed to quantify the extent of face damage and associated spalling in longwall workings.

-

A design criterion was developed for the assessment of face damage based on the profile of stress-strain redistribution.

-

The proposed criteria were used to quantify spalling and associated damage at a longwall face in three-dimension, and its results were compared with the field observation.

Similar content being viewed by others

Abbreviations

- Sc :

-

Uniaxial compressive strength

- St :

-

Brazilian tensile strength

- \({\sigma }_{h}\) :

-

Mean horizontal in situ stress

- ν:

-

Poisson’s ratio

- \(\gamma\) :

-

Unit weight of the overlying rock

- H:

-

Depth of cover

- \(\beta\) :

-

Coefficient of linear thermal expansion

- \(\mathrm{E}\) :

-

Elastic modulus

- \(\mathrm{G}\) :

-

Geothermal gradient

- \({\sigma }_{v}\) :

-

In situ vertical stress

References

Abdi H, Evgin E (2013) Laboratory characterization, modelling, and numerical simulation of an excavation damaged zone around deep geologic repositories in sedimentary rocks. Final report for Canadian Nuclear Safety Commission.

Backblom G, Martin CD (1999) Recent experiments in hard rocks to study the excavation response: implications for the performance of a nuclear waste geological repository. Tunn Undergr Space Technol 14(3):377–394. https://doi.org/10.1016/S0886-7798(99)00053-X

Bai QS, Tu SH, Zhang XG, Zhang C, Yuan Y (2014) Numerical modelling on brittle failure of coal wall in longwall face- a case study. Arab J Geosci 7:5067–5080

Bai Q, Tu S, Li Z, Tu H (2015) Theoretical analysis on the deformation characteristics of coal wall in a longwall top coal caving face. Int J Min Sci Technol 25(2):199–204

Bai QS, Tu SH, Chen M, Zhang C (2016) Numerical modeling of coal wall spall in a longwall face. Int J Rock Mech Min Sci 88:242–253

Behera B, Yadav A, Singh GSP, Sharma SK (2020a) Numerical modeling study of the geomechanical response of strata in longwall operations with particular reference to Indian geo-mining conditions. Rock Mech Rock Eng 53:1827–1856. https://doi.org/10.1007/s00603-019-02018-w

Behera B, Yadav A, Singh GSP, Sharma SK (2020b) A numerical modeling approach for evaluation of spalling associated face instability in longwall workings under massive sandstone roof. Eng Fail Anal 117:1–29

Behera B, Yadav A, Singh GSP, Sharma SK (2020c) Design of an optimum longwall face for improved ground control: a review. J Inst Eng India Ser D 101:151–164

Brown ET, Bray JW, Ladanyi B, Hoek E (1983) Ground response curves for rock tunnels. J Geotech Eng 109:12–32

Cai M, Kaiser PK, Martin CD (2001) Quantification of rock mass damage in underground excavations from microseismic event monitoring. Int J Rock Mech Min Sci 38(7):1135–1145. https://doi.org/10.1016/S1365-1609(01)00068-5

Cai M, Kaiser PK, Tasaka Y, Maejima T, Morioka H, Minami M (2004) Generalized crack initiation and crack damage stress thresholds of brittle rock masses near underground excavations. Int J Rock Mech Min Sci 41:833–847. https://doi.org/10.1016/j.ijrmms.2004.02.001

Cai M, Kaiser PK, Marioka H, Minami M, Maejima T, Tasaka Y, Kurose H (2007) FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int J Rock Mech Min Sci 44(4):550–564

Cai M (2008) Influence of intermediate principal stress on rock fracturing and strength near excavation boundaries- Insight from numerical modeling. Int J Rock Mech Min Sci 45:763–772

Cao W, Shi JQ, Si G, Durucan S, Korre A (2018) Numerical modelling of microseismicity associated with longwall coal mining. Int J Coal Geol 193:30–45

Chang JC, Xie GX, Zhang XH (2015) Analysis of rib spalling mechanism of fully-mechanized top-coal caving face with great mining height in extra-thick coal seam. Rock and Soil Mech 36(3):803–808

Das AJ, Mandal PK, Paul PS et al (2019) Assessment of the strength of inclined coal pillars through numerical modelling based on the ubiquitous joint model. Rock Mech Rock Eng 52:3691–3717

Das AJ, Mandal PK, Bhattacharjee R, Tiwari S, Kushwaha A, Roy LB (2017) Evaluation of stability of underground workings for exploitation of an inclined coal seam by the ubiquitous joint model. Int J Rock Mech Min Sci 93:101–114

Diederichs MS, Kaiser PK (1999) Tensile strength and abutment relaxation as failure control mechanisms in underground excavations. Int J Rock Mech Min Sci 36:69–96

Diederichs MS, Kaiser PK, Eberhardt E (2004) Damage initiation and propagation in hard rock during tunnelling and the influence of near face stress rotation. Int J Rock Mech Min Sci 41(5):785–812. https://doi.org/10.1016/j.ijrmms.2004.02.003

Dong FT (2001) The supporting theory based on broken rock zone and its application technology. China Coal Industry Publishing House, Bejing ((In Chinese with English Abstract))

Falls SD, Young RP (1998) Acoustic emission and ultrasonic-velocity methods used to characterize the excavation disturbance associated with deep tunnels in hard rock. Tectonophysics 289(1–3):1–15. https://doi.org/10.1016/S0040-1951(97)00303-X

Frith RC, Creech M (1997) Face width optimisation in both longwall and shortwall caving environments. ACARP project No.5015.

Golshani A, Oda M, Okui Y, Takemura T, Munkhtogoo E (2007) Numerical simulation of the excavation damaged zone around an opening in brittle rock. Int J Rock Mech Min Sci 44:835–845. https://doi.org/10.1016/j.ijrmms.2006.12.005

Gong PL (2006) Surrounding rock control theory and application study of the coal face with greater mining height. China Coal Industry Publishing House, Peking ((In Chinese))

Guo WB, Wang HS, Dong GW, Li L, Huang YG (2017) A case study of effective support working resistance and roof support technology in thick seam fully-mechanized face mining with hard roof conditions. Sustainability 9(6):1–17

Guo WB, Liu CY, Dong GW, Lv WY (2019) Analytical study to estimate rib spalling extent and support requirements in thick seam mining. Arab J Geosci 12(276):1–12

He FL, Qian MG, Liu XF, Chen LW, Li CF (1997) Tilt characteristics and control conditions of high powered support. J China Univ Min Technol 26(4):20–24 ((In Chinese))

He Z, Xie H, Gao M et al (2021) The fracturing models of hard roofs and spatiotemporal law of mining-induced stress in a top coal caving face with an extra-thick coal seam. Geomech Geophys Geo-Energ Geo-Resour 7(2):1–15. https://doi.org/10.1007/s40948-020-00202-9

Hommand-Etienne F, Hoxha D, Shao JF (1998) A continuum damage constitutive law for brittle rocks. Computer and Geotechnics 22(2): 135–151. https://doi.org/10.1016/S0266-352X(98)00003-2. https://scclmines.com/scclnew/company_about-us_godavari-valley-map.asp. http://www.rocscience.com/downloads/phase2/webhelp/phase2_model/strength_parameters.htm

Huang B, Wang Y, Cao S (2015) Cavability control by hydraulic fracturing for top coal caving in hard thick coal seams. Int J Rock Mech Min Sci 74:45–57

Itasca (2015) FLAC-3D Version 5.01 User’s Manual. Itasca Consulting Group, Inc., Minneapolis, USA.

Jaeger JC, Cook NGW (2006) Fundamentals of rock mechanics. Chapman and Hall

Jiang L, Kong P, Shu J et al (2019) Numerical analysis of support designs based on a case study of a longwall entry. Rock Mech Rock Eng 52:3373–3384

Ju J, Xu J (2013) Structural characteristics of key strata and strata behaviour of a fully mechanized longwall face with 7.0 m height chocks. Int J Rock Mech Min Sci 58:46–54

Kaiser PK, Yazici S, Maloney S (2001) Mining-induced stress change and consequences of stress path on excavation stability- a case study. Int J Rock Mech Min Sci 38(2):167–180

Kang H, Lou J, Gao F et al (2018) A physical and numerical investigation of sudden massive roof collapse during longwall coal retreat mining. Int J Coal Geol 188:25–36

Kelsall PC, Case JB, Chabannes CR (1984) Evaluation of excavation-induced changes in rock permeability. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstract 21(3):123–135. https://doi.org/10.1016/0148-9062(84)91530-4

Kong DZ, Cheng ZB, Zheng SS (2019) Study on the failure mechanism and stability control measures in a large-cutting-height coal mining face with a deep-buried seam. Bull Eng Geol Env 78(8):6143–6157

Kuang T, Li Z, Zhu W, Xie J, Ju J, Liu J, Xu J (2019) The impact of key strata movement on ground pressure behaviour in the Datong coalfield. Int J Rock Mech Min Sci 119:193–204

Kumar A, Waclawik P, Singh R, Ram S, Korbel J (2019) Performance of a coal pillar at deeper cover: Field and simulation studies. Int J Rock Mech Min Sci 113:322–332

Kushwaha A, Banerjee G (2005) Exploitation of developed coal mine pillars by shortwall minng – a case example. Int J Rock Mech Min Sci 42:127–136

Kushwaha A, Singh SK, Tewari S, Sinha A (2010) Empirical approach for designing of support system in mechanized coal pillar mining. Int J Rock Mech Min Sci 47:1063–1078

Liu C, Li H, Mitri H (2019) Effect of strata conditions on shield pressure and surface subsidence at a longwall top coal caving working face. Rock Mech Rock Eng 52:1523–1537

Liu CY, Huang BX, Chang XM, Wang J, Wei MT (2008) Study on tip-to-face coal and rock stability control of fully mechanized stepped large cutting height mining in extremely soft thick seam. J China Univ Mini Technol 37(6):734–739 ((In Chinese))

Li LC, Liu HH (2013) A numerical study of the mechanical response to excavation and ventilation around tunnels in clay rocks. Int J Rock Mech Min Sci 59:22–32. https://doi.org/10.1016/j.ijrmms.2012.11.005

Li XP, Kang TH, Yang YK, LI H, Li CY, Wu LL, Du MZ, (2015) Analysis of coal wall slip risk and caving depth based on Bishop Method. J China Coal Soc 40:1498–1504

Lu Y, Gong T, Xia B, Yu B, Huang F (2019) Target stratum determination of surface hydraulic fracturing for far field hard roof control in underground extra-thick coal extraction: A case study. Rock Mech Rock Eng 52:2725–2740

Lv Z, Huang HZ, Zhu SP, Gao H, Zuo F (2015) A modified nonlinear fatigue damage accumulation model. Int J Damage Mech 24(2):168–181. https://doi.org/10.1177/1056789514524075

Mandal PK, Singh R, Maiti J, Singh AK, Kumar R, Sinha A (2008) Underpinning-based simultaneous extraction of contiguous sections of a thick coal seam under weak and laminated partings. Int J Rock Mech Min Sci 45:11–28

Mandal PK, Das AJ, Kumar N, Bhattacharjee R, Tewari S, Kushwaha A (2018) Assessment of roof convergence during driving roadways in underground coal mines by continuous miner. Int J Rock Mech Min Sci 108:169–178

Martin CD, Kaiser PK, Christiansson R (2003) Stress, instability and design of underground excavations. Int J Rock Mech Min Sci 40:1027–1047

Martino JB, Chandler NA (2004) Excavation-induced damage studies at the underground research laboratory. Int J Rock Mech Min Sci 41:1413–1426

Medhurst TP, Reed K (2005) Ground response curves for longwall support assessment. Min Technol 114:A81–A88

Mohan GM, Sheorey PR, Kushwaha A (2001) Numerical estimation of pillar strength in coal mines. Int J Rock Mech Min Sci 38:1185–1192

Ning Y (2009) Mechanism and control technique of the rib spalling in fully mechanized mining face with great mining height. J China Coal Soc 34(1): 50–52, 9 (In Chinese).

Niu Y, Chen S, Liu J (2010) Analysis on spalling increased mechanism of fully mechanized high cutting coal mining face and prevention measures. Coal Sci Technol 38(7):38–40

Palchik V (2015) Bulking factors and extents of caved zones in weathered overburden of shallow abandoned underground workings. Int J Rock Mech Min Sci 79:227–240

Pellet F, Roosefid M, Deleruyelle F (2009) On the 3D numerical modelling of the time-dependent development of the damage zone around underground galleries during and after excavation. Tunn Undergr Space Technol 24:665–674. https://doi.org/10.1016/j.tust.2009.07.002

Peng SS (2006) Longwall mining, 2nd edn. Society for Mining, Metallurgy, and Exploration, Inc. (SME), Englewood.

Perras MA, Wannenmacher H, Diederichs MS (2015) Underground excavation behavior of the queenston formation: tunnel back analysis for application to shaft damage dimension prediction. Rock Mech Rock Eng 48(4):1647–1671. https://doi.org/10.1007/s00603-014-0656-z

Perras MA, Diederichs MS (2016) Predicting excavation damage zone depths in brittle rocks. J Rock Mech Geotech Eng 8:60–74. https://doi.org/10.1016/j.jrmge.2015.11.004

Pusch R (1989) Alteration of the hydraulic conductivity of rock by tunnel excavation. Int J Rock Mech Min Sci Geomech Abst 26(1):79–83. https://doi.org/10.1016/0148-9062(89)90528-7

Pusch R, Stanfors R (1992) The zone of disturbance around blasted tunnels at depth. Int J Rock Mech Min Sci Geomech Abst 29(5):447–456. https://doi.org/10.1016/0148-9062(92)92629-Q

Rao MS, Bhaskar GU (2015) Geological and geotechnical characterisation using geophysical logs - an example from adriyala longwall project of Singareni Collieries, India. ASEG Extended Abstracts 1:1–5

Rezaei M, Hossaini MF, Majdi A (2015) Determination of longwall mining-induced stress using strain energy method. Rock Mech Rock Eng 48:2421–2433

Sarkar SK (1998) Mechanized longwall mining – the Indian experiences. Oxford and IBH publishing company private limited, New Delhi

Sheorey PR (1994) A theory for in situ stresses in isotropic and transversely isotropic rock. Int J Rock Mech Min Sci Geomech Abst 31:23–34

Sheorey PR, Mohan GM, Sinha A (2001) Influence of elastic constants on the horizontal in situ stress. Int J Rock Mech Min Sci Geomech Abst 38:1211–6

Singh GSP, Singh UK (2004) Cavability assessment model for longwall workings in India. In: Proceedings of the third Asian rock mechanics symposium, Kyoto, 295–300.

Singh GSP, Singh UK (2009) A numerical modeling approach for assessment of progressive caving of strata and performance of hydraulic powered support in longwall workings. Comput Geotech 36(7):1142–1156

Singh GSP, Singh UK (2010a) Numerical modeling study of the effect of some critical parameters on caving behavior of strata and support performance in a longwall working. Rock Mech Rock Eng 43:475–489

Singh GSP, Singh UK (2010b) Prediction of caving behaviour of strata and optimum rating of hydraulic powered support for longwall workings. Int J Rock Mech Min Sci 47(1):1–16

Singh AK, Singh R, Maiti J, Kumar R, Mandal PK (2011) Assessment of mining induced stress development over coal pillars during depillaring. Int J Rock Mech Min Sci 48:805–818

Singh R, Kumar A, Singh AK, Coggen J, Ram S (2016) Rib/snook design in mechanised depillaring of rectangular/square pillars. Int J Rock Mech Min Sci 84:119–129

Siren T, Kantia P, Rinne M (2015) Considerations and observations of stress-induced and construction-induced excavation damage zone in crystalline rock. Int J Rock Mech Min Sci 73:165–174

Smart BGD, Aziz NI (1986) The influence of caving in the Hirst and Bulli seams on powered support rating. In: Proceedings of the symposium on ground movement and control related to coal mining, Organized by the Australian Institute of Mining and Metallurgy, Illawara Branch, University of Wollongong, August 1986: 1–12.

Song HW (1999) Expert system for bolt shortcrete support design based on the supporting theory of broken rock zone. J China Univ Min Technol 28(6):565–568

Song G, Chugh YP (2017) A numerical modelling study of longwall face stability in mining thick coal seams in China. Int J Min Mineral Eng 8(1):35–55

Song G, Chugh YP (2018) 3D analysis of longwall face stability in thick coal seams. J South Afr Inst Min Metall 118:131–142

Souley M, Renaud V, Al Heib M et al (2018) Numerical investigation of the development of the excavation damaged zone around a deep polymetallic ore mine. Int J Rock Mech Min Sci 106:165–175

Tsang CF, Bernier F, Davies C (2005) Geohydromechanical processes in the excavation damaged zone in crystalline rock, rock salt, and indurated and plastics clays- in the context of radioactive waste disposal. Int J Rock Mech Min Sci 42:109–125

Tu SH, Yuan Y (2012) Theory and practice of fully-mechanized working face with great mining height in thick coal seam. Chin Uni Min Tech Press, Xuzhou ((In Chinese))

Vazaios I, Vlachopoulos N, Diederichs MS (2019) Assessment fracturing mechanism and evolution of excavation damaged zone of tunnels in interlocked rock masses at high stresses using a finite-discrete element approach. J Rock Mech Geotech Eng 11(4):701–722. https://doi.org/10.1016/j.jrmge.2019.02.004

Wang JC (2007) Mechanism of the rib spalling and the controlling in the very soft coal seam. J China Coal Soc 32(8):785–788 ((In Chinese))

Wang JC, Wang L, Guo Y (2014) Determining the support capacity based on roof and coal wall control. J China Coal Soc 39:1619–1624

Wang H, Jiang Y, Xue S, Shen B, Wang C, Lv J, Yang T (2015) Assessment of excavation damaged zone around roadways under dynamic pressure induced by an active mining process. Int J Rock Mech Min Sci 77:265–277. https://doi.org/10.1016/j.ijrmms.2015.03.032

Wang J, Ning J, Jiang J, Bu T, Shi X (2017) Research on the energy criterion for rockbursts induced by broken hard and thick rock strata and its application. Geotech Geol Eng 35(2):731–746

Wang F, Jiang B, Chen S et al (2019a) Surface collapse control under thick unconsolidated layers by backfilling strip mining in coal mines. Int J Rock Mech Min Sci 113:268–277

Wang F, Xu J, Xie J (2019b) Effects of arch structure in unconsolidated layers on fracture and failure of overlying strata. Int J Rock Mech Min Sci 114:241–152

Wilson AH (1980) The stability of underground workings in the soft rocks of the coal measures. Ph.D. Dissertation, University of Nottingham, UK

Wilson CR, Witherspoon PA, Long JCS, Galbraith RM, DuBois AO, McPherson MJ (1983) Large-scale hydraulic conductivity measurements in fractured granite. Int J Rock Mech Min Sci Geomech Abst 20(6):269–276. https://doi.org/10.1016/0148-9062(83)90596-X

Wu Z, Jiang Y, Liu Q, Ma H (2018) Investigation of the excavation damaged zone around deep TBM tunnel using a Voronoi-element based explicit numerical manifold method. Int J Rock Mech Min Sci 112:158–170. https://doi.org/10.1016/j.ijrmms.2018.10.022

Wu K, Shao Z, Qin S (2020) An analytical design method for ductile support structures in squeezing tunnels. Archiv Civ Mech Eng 20:91

Xie HP, Gao F, Ju Y (2015) Research and development of rock mechanics in deep ground engineering. Chin J Rock Mech Eng 34(11):2161–2178

Xu T, Yang Th, Cf C et al (2015) Mining induced strata movement and roof behavior in underground coal mine. Geomech Geophys Geo-Energ Geo-Resour 1:79–89. https://doi.org/10.1007/s40948-015-0010-2

Xu J, Rui Z, Song D, Li N, Zhang K, Xi D (2017) Deformation and damage dynamic characteristics of coal-rock materials in deep coal mines. Int J Damage Mech https://doi.org/10.1177/1056789517741950

Yang HQ, Zeng YY, Lan YF et al (2014) Analysis of the excavation damaged zone around a tunnel accounting for geostress and unloading. Int J Rock Mech Min Sci 69:59–66

Yang SQ, Chen M, Jing HW, Chen KF, Meng B (2017) A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China. Eng Geol 217:89–101

Yang S, Song G, Kong D (2019) An evaluation of longwall face stability in thick coal seams through a basic understanding of shield-strata interaction. Journal of Geophysics and Engineering 0: 1–11.

Yuan Y, Tu S, Wu Q, Ma X, Tu H, Sun L (2012a) Mechanics of rib spalling of high coal walls under fully-mechanized mining. Min Sci Technol (china) 21(1):129–133

Yuan Y, Tu SH, Ma XT, Sun LL, Bai QS (2012b) Coal wall stability of fully mechanized working face with great mining height in ‘three soft’ coal seam and its control technology. J Min Saf Eng 29:21–25

Zhang Q, Yue J, Liu C et al. (2019) Study of automated top-coal caving in extra-thick coal seams using the continumm-discontinuum element method. International Journal of Rock Mechanics and Mining Sciences 122: 104033.

Zhao XG, Cai M (2010) A mobilized dilation angle model for rocks. Int J Rock Mech Min Sci 47:368–384

Zhu WC, Wei J, Zhao J, Niu LL (2014) 2D numerical simulation on excavation damaged zone induced by dynamic stress redistribution. Tunn Undergr Space Technol 43:315–326. https://doi.org/10.1016/j.tust.2014.05.023

Zhu S, Feng Y, Jiang F (2016) Determination of abutment pressure in coal mines with extremely thick alluvium stratum: a typical kind of rockburst mines in China. Rock Mech Rock Eng 49:1943–1952

Zhu GA, Dou LM, Wang CB, Li J, Cai W (2017) Numerical investigation of the evolution of overlying strata and distribution of static and dynamic loads in a deep island coal panel. Arab J Geosci 10(549):1–22

Acknowledgements

The authors are grateful to the Head, Department of Mining Engineering, Indian Institute of Technology (BHU) Varanasi, for providing the requisite infrastructure to complete the study. The authors submit their sincere gratitude to the mine management for providing necessary information related to this research work. The views shared in this work are the opinions of the authors and not necessarily of the organization to which they belong.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Behera, B., Yadav, A., Singh, G.S.P. et al. Assessment of excavation damage and spalling potential at a mechanized longwall face: a numerical modeling study. Geomech. Geophys. Geo-energ. Geo-resour. 7, 104 (2021). https://doi.org/10.1007/s40948-021-00299-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40948-021-00299-6