Abstract

Purpose

Electrospinning is a versatile method with a broad range of applications, including in biomaterials. In this study, an electrospinning apparatus was built to fabricate polycaprolactone (PCL) fibrous biomaterials for future use as a fibrocartilage tissue engineering scaffold. The properties of the resultant fibers were determined by many factors, thus understanding the effects of the factors was required for optimizing the process.

Methods

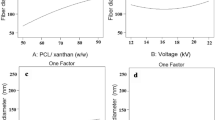

For screening the important factors and studying the relationship between these factors and fiber output, an experiment using factorial design was carried out. The investigation was focused on the processing parameters tunable from the apparatus setup, including flow rate, collector distance, and collector rotation speed. Optimization was carried out to estimate the best combination of processing parameters to achieve the optimal fiber characteristics, specifically fiber diameter and elastic modulus.

Results

All three parameters under study showed a significant effect on fiber properties, either as single or interacting variables. The optimized setup produced fibrous structures with an average fiber diameter of 1.7 µm and an elastic modulus of 25 MPa.

Conclusion

This study demonstrated that factorial design could be advantageous for optimizing electrospinning apparatus, thereby providing a basis for further development and optimization of electrospinning technologies for the fabrication of fibrous scaffolds.

Lay Summary

An electrospinning tool was constructed to fabricate fiber-based biomaterials for future use as fibrocartilage tissue engineering scaffolds. The characteristics of the electrospun fiber depend on many factors; hence, a factorial experiment was conducted to study the relationship between processing factors and the fiber output, followed by an optimization procedure. The outcome of the optimized setup was a fibrous membrane with fiber properties potentially suitable for tissue engineering applications. This study also showed that the electrospinning process, a complex multivariate system, could be optimized using factorial design, hence laying a basis for further development of other electrospinning technologies.

Similar content being viewed by others

Data and Materials Availability

Not applicable.

Code Availability

Not applicable.

References

Reneker DH, Yarin AL, Fong H, Koombhongse S. Bending instability of electrically charged liquid jets of polymer solutions in electrospinning. J Appl Phys. 2000;104(9):4531–47. https://doi.org/10.1063/1.373532.

Li D, Xia Y. Electrospinning of nanofibers: reinventing the wheel? Adv Mater. 2004;16(14):1151–70. https://doi.org/10.1002/adma.200400719.

Liao C-C, Wang C-C, Shih K-C, Chen C-Y. Electrospinning fabrication of partially crystalline bisphenol A polycarbonate nanofibers: effects on conformation, crystallinity, and mechanical properties. Eur Polymer J. 2011;47(5):911–24. https://doi.org/10.1016/j.eurpolymj.2011.01.006.

Kim HW, Kim HE, Knowles JC. Production and potential of bioactive glass nanofibers as a next-generation biomaterial. Adv Funct Mater. 2006;16(12):1529–35. https://doi.org/10.1002/adfm.200500750.

Reneker DH, Chun I. Nanometre diameter fibers of polymer, produced by electrospinning. Nanotechnology. 1996;7(3):216–23. https://doi.org/10.1088/0957-4484/7/3/009.

Alehosseini A, Ghorani B, Sarabi-Jamab M, Tucker N. Principles of electrospraying: a new approach in protection of bioactive compounds in foods. 2018;58:2346–63.https://doi.org/10.1080/10408398.2017.1323723

Hao L, Christopher RG, Qianqian D, Zhenggui G, Fang W, Xiao H. Recent advances in electrospun sustainable composites for biomedical, environmental, energy, and packaging applications. Int J Mol Sci. 2020;21(4019):4019. https://doi.org/10.3390/ijms21114019.

Qin X, Wu D. Effect of different solvents on poly(caprolactone) (PCL) electrospun nonwoven membranes. J Therm Anal Calorim. 2012;107(3):1007–13. https://doi.org/10.1007/s10973-011-1640-4.

Pham QP, Sharma U, Mikos AG. Electrospinning of polymeric nanofibers for tissue engineering applications: a review. Tissue Eng. 2006;12(5):1197–211. https://doi.org/10.1089/ten.2006.12.1197.

Bosworth L, Downes S. Acetone, a sustainable solvent for electrospinning poly(ε-caprolactone) fibers: effect of varying parameters and solution concentrations on fiber diameter. J Polym Environ. 2012;20(3):879–86. https://doi.org/10.1007/s10924-012-0436-3.

Choi JS, Lee SJ, Christ GJ, Atala A, Yoo JJ. The influence of electrospun aligned poly(ɛ-caprolactone)/collagen nanofiber meshes on the formation of self-aligned skeletal muscle myotubes. Biomaterials. 2008;29(19):2899–906. https://doi.org/10.1016/j.biomaterials.2008.03.031.

Kishan AP, Cosgriff-Hernandez EM. Recent advancements in electrospinning design for tissue engineering applications: a review. J Biomed Mater Res, Part A. 2017;105:2892–905. https://doi.org/10.1002/jbm.a.36124.

Naghizadeh F, Solouk A, Khoulenjani SB. Osteochondral scaffolds based on electrospinning method: general review on new and emerging approaches. Int J Polym Mater Polym Biomater. 2018;67:913–24. https://doi.org/10.1080/00914037.2017.1393682.

Biazar E. Application of polymeric nanofibers in soft tissues regeneration. Polym Adv Technol. 2016;27:1404–12. https://doi.org/10.1002/pat.3820.

Scaffaro R, Lopresti F, Maio A, Sutera F, Botta L. Development of Polymeric Functionally Graded Scaffolds: A Brief Review. London, England: SAGE Publications; 2017. p. 107–21.

Li G, Zhou T, Lin S, Shi S, Lin Y. Nanomaterials for craniofacial and dental tissue engineering. J Dent Res. 2017;96:725–32. https://doi.org/10.1177/0022034517706678.

Kakade MV, Givens S, Gardner K, Lee KH, Chase DB, Rabolt JF. Electric field induced orientation of polymer chains in macroscopically aligned electrospun polymer nanofibers. J Am Chem Soc. 2007;129(10):2777–82. https://doi.org/10.1021/ja065043f.

Suja PS, Reshmi CR, Sagitha P, Sujith A. Electrospun nanofibrous membranes for water purification. Polym Rev. 2017;57:467–504. https://doi.org/10.1080/15583724.2017.1309664.

Duling RR, Dupaix RB, Katsube N, Lannutti J. Mechanical characterization of electrospun Polycaprolactone (PCL): a potential scaffold for tissue engineering. J Biomech Eng. 2008;130(1): 011006. https://doi.org/10.1115/1.2838033.

Lannutti J, Reneker D, Ma T, Tomasko D, Farson D. Electrospinning for tissue engineering scaffolds. Mater Sci Eng, C. 2007;27(3):504–9. https://doi.org/10.1016/j.msec.2006.05.019.

Liao C-C, Wang C-C, Chen C-Y. Stretching-induced crystallinity and orientation of polylactic acid nanofibers with improved mechanical properties using an electrically charged rotating viscoelastic jet. Polymer. 2011;52(19):4303–18. https://doi.org/10.1016/j.polymer.2011.07.031.

Liu YY, Jing CJ, Liu DL, Hu QX. Research on high quality nanofiber electrospinning manufacturing system: detecting method of Taylor-cone and Fiber diameter Control Strategy. Przeglad Elektrotechniczny. 2012;88(9B):17–21.

Doshi J, Reneker DH. Electrospinning process and applications of electrospun fibers. J Electrostat. 1995;35(2–3):151–60. https://doi.org/10.1016/0304-3886(95)00041-8.

Wu C-M, Hsu C-H, Su C-I, Liu C-L, Lee J-Y. Optimizing parameters for continuous electrospinning of polyacrylonitrile nanofibrous yarn using the Taguchi method. J Ind Text. 2018;48(3):559–79. https://doi.org/10.1177/1528083717740741.

Chen Y-P, Liu H-Y, Liu Y-W, Lee T-Y, Liu S-J. Determination of electrospinning parameters’ strength in poly(D,L)-lactide-co-glycolide micro/nanofiber diameter tailoring. J Nanomater 2019;2019. https://doi.org/10.1155/2019/2626085.

Borrotti M, Lanzarone E, Manganini F, Ortelli S, Pievatolo A, Tonetti C. Defect minimization and feature control in electrospinning through design of experiments. J Appl Polym Sci. 2017. https://doi.org/10.1002/app.44740.

Stoddard R, Chen X. Electrospinning of ultra-thin nanofibers achieved through comprehensive statistical study. Mater Res Exp. 2016;3(5): 055022. https://doi.org/10.1088/2053-1591/3/5/055022.

Yousefi Abdolmaleki A, Zilouei H, Nouri Khorasani S, Abdolmaleki A. Optimization and characterization of electrospun chitosan/poly(vinyl alcohol) nanofibers as a phenol adsorbent via response surface methodology. Polym Adv Technol. 2017;28(12):1872–8. https://doi.org/10.1002/pat.4075.

Mandenius CF, Brundin A. Bioprocess optimization using design-of-experiments methodology. Biotechnol Prog. 2008;24:1191–203. https://doi.org/10.1002/btpr.67.

Nonato RC, Morales AR, Vieira AF, Nista SV, Mei LH, Bonse BC. Solution parameters in the manufacture of ceramic ZnO nanofibers made by electrospinning. Appl Phys A. 2016;122(3):244. https://doi.org/10.1007/s00339-016-9752-0.

Korycka P, Mirek A, Kramek-Romanowska K, Grzeczkowicz M, Lewińska D. Effect of electrospinning process variables on the size of polymer fibers and bead-on-string structures established with a 2 3 factorial design. Beilstein J Nanotechnol. 2018;9:2466–78. https://doi.org/10.3762/bjnano.9.231.

Enis I, Sezgin H, Sadikoglu T. Full factorial experimental design for mechanical properties of electrospun vascular grafts. J Ind Text. 2017;47(6):1378–91. https://doi.org/10.1177/1528083717690614.

Nottelet B, Pektok E, Mandracchia D, Tille JC, Walpoth B, Gurny R, et al. Factorial design optimization and in vivo feasibility of poly(ε-caprolactone)-micro- and nanofiber-based small diameter vascular grafts. J Biomed Mater Res, Part A. 2009;89A(4):865–75. https://doi.org/10.1002/jbm.a.32023.

Huan S, Liu G, Han G, Cheng W, Fu Z, Wu Q, et al. Effect of experimental parameters on morphological, mechanical and hydrophobic properties of electrospun polystyrene fibers. Materials. 2015;8(5):2718–34. https://doi.org/10.3390/ma8052718.

Doustgani A. Optimization of mechanical and structural properties of PVA nanofibers. 2016;46(3):901–13.https://doi.org/10.1177/1528083715601511

Lasprilla-Botero J, Álvarez-Láinez M, Lagaron JM. The influence of electrospinning parameters and solvent selection on the morphology and diameter of polyimide nanofibers. Mater Today Commun. 2018;14:1–9. https://doi.org/10.1016/j.mtcomm.2017.12.003.

Noreña-Caro D, Alvarez-Láinez M. Experimental design as a tool for the manufacturing of filtering media based on electrospun polyacrylonitrile/ $$\upbeta $$ β -cyclodextrin fibers. Int J Interact Des Manuf. 2014;10(2):153–64. https://doi.org/10.1007/s12008-014-0241-4.

Petersen W, Petersen F, Tillmann B. Structure and vascularization of the acetabular labrum with regard to the pathogenesis and healing of labral lesions. Arch Orthop Trauma Surg. 2003;123(6):283–8. https://doi.org/10.1007/s00402-003-0527-7.

Montgomery DC, Runger GC. Applied Statistics and Probability for Engineers. 6th ed. Hoboken: Wiley; 2014.

Montgomery DC. Design and analysis of experiments. vol Book, Whole. Hoboken: Wiley; 2005.

Smith CD, Masouros S, Hill AM, Amis AA, Bull AMJ. A biomechanical basis for tears of the human acetabular labrum. Br J Sports Med. 2009;43(8):574–8. https://doi.org/10.1136/bjsm.2008.053645.

Anonymous. MINITAB User's Guide 2: Data Analysis and Quality Tools. Release 13 ed. Minitab Inc.; 2000.

Ki CS, Baek DH, Gang KD, Lee KH, Um IC, Park YH. Characterization of gelatin nanofiber prepared from gelatin–formic acid solution. Polymer. 2005;46(14):5094–102. https://doi.org/10.1016/j.polymer.2005.04.040.

Zhang C, Yuan X, Wu L, Han Y, Sheng J. Study on morphology of electrospun poly(vinyl alcohol) mats. Eur Polymer J. 2005;41(3):423–32. https://doi.org/10.1016/j.eurpolymj.2004.10.027.

Zhao Z, Li J, Yuan X, Li X, Zhang Y, Sheng J. Preparation and properties of electrospun poly(vinylidene fluoride) membranes. J Appl Polym Sci. 2005;97(2):466–74. https://doi.org/10.1002/app.21762.

Yuan X, Zhang Y, Dong C, Sheng J. Morphology of ultrafine polysulfone fibers prepared by electrospinning. Polym Int. 2004;53(11):1704–10. https://doi.org/10.1002/pi.1538.

Khan SP, Bhasin K, Newaz GM, editors. Optimizing process variables to control fiber diameter of electrospun polycaprolactone nanofiber using factorial design. Symposium QQ – Nanofunctional Materials, Nanostructures and Nanodevices for Biomedical Applications II; 2011 2011: Cambridge University Press.

Edwards MD, Mitchell GR, Mohan SD, Olley RH. Development of orientation during electrospinning of fibers of poly(ε-caprolactone). Eur Polymer J. 2010;46(6):1175–83. https://doi.org/10.1016/j.eurpolymj.2010.03.017.

Koepsell L, Remund T, Bao J, Neufeld D, Fong H, Deng Y. Tissue engineering of annulus fibrosus using electrospun fibrous scaffolds with aligned polycaprolactone fibers. J Biomed Mater Res, Part A. 2011;99A(4):564–75. https://doi.org/10.1002/jbm.a.33216.

Naraghi M, Arshad SN, Chasiotis I. Molecular orientation and mechanical property size effects in electrospun polyacrylonitrile nanofibers. Polymer. 2011;52(7):1612–8. https://doi.org/10.1016/j.polymer.2011.02.013.

Lee KH, Kim HY, Khil MS, Ra YM, Lee DR. Characterization of nano-structured poly(ε-caprolactone) nonwoven mats via electrospinning. Polymer. 2003;44(4):1287–94. https://doi.org/10.1016/S0032-3861(02)00820-0.

Tan EPS, Ng SY, Lim CT. Tensile testing of a single ultrafine polymeric fiber. Biomaterials. 2005;26(13):1453–6. https://doi.org/10.1016/j.biomaterials.2004.05.021.

Bölgen N, Menceloğlu YZ, Acatay K, Vargel İ, Pişkin E. In vitro and in vivo degradation of non-woven materials made of poly(ε-caprolactone) nanofibers prepared by electrospinning under different conditions. J Biomater Sci Polym Ed. 2005;16(12):1537–55. https://doi.org/10.1163/156856205774576655.

Smith MV, Costic RS, Allaire R, Schilling PL, Sekiya JK. A biomechanical analysis of the soft tissue and osseous constraints of the hip joint. Knee Surg Sports Traumatol Arthrosc. 2012;22(4):946–52. https://doi.org/10.1007/s00167-012-2255-4.

Discher DE, Janmey P, Wang Y-l. Tissue cells feel and respond to the stiffness of their substrate. Science. 2005;310(5751):1139–43. https://doi.org/10.1126/science.1116995.

Lo CM, Wang HB, Dembo M, Wang YL. Cell movement is guided by the rigidity of the substrate. Biophys J . 2000;79(1):144–52.

Acknowledgements

The authors acknowledge the facilities and the scientific and technical assistance of the Australian Microscopy and Microanalysis Research Facility at the Australian Centre for Microscopy and Microanalysis at the University of Sydney.

Funding

This study was undertaken as a part of Ph.D. program funded by Australia Awards.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Anindyajati, A., Boughton, P. & Ruys, A.J. Study on Processing Parameters of Polycaprolactone Electrospinning for Fibrous Scaffold using Factorial Design. Regen. Eng. Transl. Med. 8, 321–333 (2022). https://doi.org/10.1007/s40883-021-00228-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40883-021-00228-9