Abstract

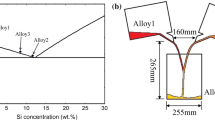

The Al-AlN-Si composites were prepared in the gas-in-liquid in situ synthesized flow-reaction-system, which was implemented by a powder metallurgy and reaction sintering route. The experimental results showed that Al-AlN-50SiB material (prepared by ball-milling powders) and Al- AlN-50SiM material (prepared by mixing powders) exhibited the semi-continuous Si structures and the isolated Si islands, respectively. Subsequently, the Al-AlN-50Si materials were selected as the model materials by phase identification and microstructure analysis. The dynamic microstructural evolution of Al-AlN-50Si materials was investigated using the computational fluid dynamics (CFD) method. Mathematical models and simulation results showed that the in situ synthesis of AlN was strongly influenced by the structure and the flowpath \(\left( {\left( {c_{g,N_2 } /l_{g,N_2 } } \right) + \left( {c_{s,AlN} /l_{s,AlN} } \right)} \right)\). The flow paths of Al-AlN-50SiB material were restricted by the semi-continuous Si. These Si structures can promote the formation of the strong turbulence with gradually weakened fluctuation, so that the in situ synthesis of AlN was interconnected and surrounded by an interpenetrating Si network. In contrast, the flow paths of Al-AlN-50SiM material can easily pass through the isolated Si due to its mild turbulence with linear relationship. As a result, AlN was separated by the isolated Si and agglomerated in the matrix. Overall, the present work provides new insights into dynamic microstructural evolution in in situ reaction sintering systems.

摘要

本文采用粉末冶金结合原位反应方法制备了不同结构的Al-AlN-Si复合材料. 基于物相鉴别和显微分析方法, 建立了具有半连续Si结构(由高能球磨粉末制备)和孤岛Si结构(由混合粉末制备)的Al-AlN-50Si微观模型, 使用计算流体动力学(CFD)方法对Al-AlN-50Si微观组织形成过程进行了研究, 并分析了其动力学演变机理. 数学模型和模拟结果表明: 微观结构和流动路径\(\left( {\left( {c_{g,N_2 } /l_{g,N_2 } } \right) + \left( {c_{s,AlN} /l_{s,AlN} } \right)} \right)\)会强烈影响AlN的原位合成. 对于Al-AlN-50SiB(由高能球磨粉末制备)材料, 其流动路径会被半连续Si结构限制而促进强湍流的形成, 这种逐渐减弱的强湍流使AlN原位合成在Si骨架周围并呈现出相互贯穿的组织结构; 相比之下, 在Al-AlN-50SiM(由混合粉末制备)材料内部会形成线性趋势的弱湍流, 其流动路径可以很容易的绕开孤岛Si, 使AlN相被隔离并富集形成在基体中. 该工作为原位反应系统中复合材料微观组织动力学演变过程的研究提供了新的思路.

Similar content being viewed by others

References

Kang N, Coddet P, Chen C, et al. Microstructure and wear behavior of in-situ hypereutectic Al–high Si alloys produced by selective laser melting. Mater Des, 2016, 99: 120–126

Swaminathan S, Srinivasa Rao B, Jayaram V. The production of AlN-rich matrix composites by the reactive infiltration of Al alloys in nitrogen. Acta Mater, 2002, 50: 3095–3106

Qiu J, Zhao M, Zhao Q, et al. Aluminum-based materials for advanced battery systems. Sci China Mater, 2017, 60: 577–607

Wang Y, Guan R, Hou D, et al. The effects of eutectic silicon on grain refinement in an Al–Si alloy processed by accumulative continuous extrusion forming. J Mater Sci, 2017, 52: 1137–1148

Chen C, Cui C, Zhao L, et al. The formation mechanism and interface structure characterization of in situ AlN/Al composites. J Composite Mater, 2016, 50: 495–506

Ye HZ, Liu XY, Luan B. In situ synthesis of AlN particles in Mg–Al alloy by Mg3N2 addition. Mater Lett, 2004, 58: 2361–2364

Kondoh K, Kimura A, Watanabe R. Cavitation toughness of in situ nitrided Al–AlN composite sintered material. Powder Metallurgy, 2001, 44: 157–160

Wang Z, Tong Y, Wang Y. Promoting effect of silicon particles on gas-diffusion-reaction system: In-situ synthesis of AlN in Al-Si materials. J Alloys Compd, 2018, 735: 13–22

Lee KB, Sim HS, Kwon H. Fabrication of Al/AlN composites by in situ reaction. J Mater Sci, 2006, 41: 6347–6352

Ye HZ, Liu XY, Luan B. In situ synthesis of AlN in Mg–Al alloys by liquid nitridation. J Mater Processing Tech, 2005, 166: 79–85

Zheng Q, Reddy RG. Mechanism of in situ formation of AlN in Al melt using nitrogen gas. J Mater Sci, 2004, 39: 141–149

Kobatake H, Brillo J, Schmitz J, et al. Surface tension of binary Al–Si liquid alloys. J Mater Sci, 2015, 50: 3351–3360

Fatahalla N, Hafiz M, Abdulkhalek M. Effect of microstructure on the mechanical properties and fracture of commercial hypoeutectic Al-Si alloy modified with Na, Sb and Sr. J Mater Sci, 1999, 34: 3555–3564

Heiberg G, Nogita K, Dahle AK, et al. Columnar to equiaxed transition of eutectic in hypoeutectic aluminium–silicon alloys. Acta Mater, 2002, 50: 2537–2546

Shahani AJ, Gulsoy EB, Roussochatzakis VJ, et al. The dynamics of coarsening in highly anisotropic systems: Si particles in Al–Si liquids. Acta Mater, 2015, 97: 325–337

Zhang Q, Liu X, Dai H. Re-formation of AlP compound in Al–Si melt. J Alloys Compd, 2009, 480: 376–381

Zuo M, Zhao D, Teng X, et al. Effect of P and Sr complex modification on Si phase in hypereutectic Al–30Si alloys. Mater Des, 2013, 47: 857–864

Kalemtas A, Topates G, Bahadir O, et al. Thermal properties of pressureless melt infiltrated AlN–Si–Al composites. Trans Nonferrous Met Soc China, 2013, 23: 1304–1313

Myhr OR, Grong Ø, Fjær HG, et al. Modelling of the microstructure and strength evolution in Al–Mg–Si alloys during multistage thermal processing. Acta Mater, 2004, 52: 4997–5008

Arik H. Effect of mechanical alloying process on mechanical properties of a-Si3N4 reinforced aluminum-based composite materials. Mater Des, 2008, 29: 1856–1861

Wu Y, Zong Y, Jin J. Grain growth in a nanostructured AZ31 Mg alloy containing second phase particles studied by phase field simulations. Sci China Mater, 2016, 59: 355–362

Wu M, Ludwig A. Modeling equiaxed solidification with melt convection and grain sedimentation—I: Model description. Acta Mater, 2009, 57: 5621–5631

Eiken J, Apel M, Liang SM, et al. Impact of P and Sr on solidification sequence and morphology of hypoeutectic Al–Si alloys: Combined thermodynamic computation and phase-field simulation. Acta Mater, 2015, 98: 152–163

Yuan P, Gu D, Dai D. Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Mater Des, 2015, 82: 46–55

Wang Z, Wang F Z, Wang X, et al. Three-dimensional modelling and numerical simulation on segregation during Fe-Pb alloy solidification in a multiphase system. Acta Phys Sin, 2014, 63: 205-211

Wang Z, Wang F, He Y, et al. Numerical study on free-cutting phase precipitation behavior in Fe-Bi-Mn ternary alloy multiphase transformation-diffusion system. Acta Metall Sin, 2014, 50: 1393-1402

Wu M, Li J, Ludwig A, et al. Modeling diffusion-governed solidification of ternary alloys–Part 1: Coupling solidification kinetics with thermodynamics. Comput Mater Sci, 2013, 79: 830–840

Huang LJ, Geng L, Peng HX. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog Mater Sci, 2015, 71: 93–168

Suehiro T, Tatami J, Meguro T, et al. Synthesis of spherical AlN particles by gas-reduction-nitridation method. J Eur Ceramic Soc, 2002, 22: 521–526

Kim WY, Kang JG, Park CH, et al. Thermodynamics of aluminum, nitrogen and AlN formation in liquid iron. ISIJ Int, 2007, 47: 945–954

Beckermann C, Viskanta R. Mathematical modeling of transport phenomena during alloy solidification. Appl Mech Rev, 1993, 46:1

Madison J, Spowart J, Rowenhorst D, et al. Modeling fluid flow in three-dimensional single crystal dendritic structures. Acta Mater, 2010, 58: 2864–2875

Založnik M, Combeau H. Thermosolutal flow in steel ingots and the formation of mesosegregates. Int J Thermal Sci, 2010, 49: 1500–1509

Duhr S, Braun D. Two-dimensional colloidal crystals formed by thermophoresis and convection. Appl Phys Lett, 2005, 86: 131921

Acknowledgements

This work was supported by the financial support of the National Natural Science Foundation of China (51171146 and 51101177) and the Program for Key Science and Technology Innovative Research Team of Shaanxi Province (2013KCT-05).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Zhe Wang is now a PhD candidate of the School of Sciences, Xi’an Jiaotong University. His research interests focus on the preparation and properties of Al-Si based composites and their applications in electronic packaging.

Yaping Wang received his PhD degree in material science from Xi’an Jiaotong University in 1998. Currently, he is a professor at Xi’an Jiaotong University. His research interests include non-pressure impregnation of Si-Al electrical packaging materials, preparation of Cu-Cr and Ag-SnO2 contact materials and industrial manufacture of Cu-Al2O3 composite materials.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Wang, Z., Wang, X., Tong, Y. et al. Impact of structure and flow-path on in situ synthesis of AlN: Dynamic microstructural evolution of Al-AlN-Si materials. Sci. China Mater. 61, 948–960 (2018). https://doi.org/10.1007/s40843-017-9198-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-017-9198-4