Abstract

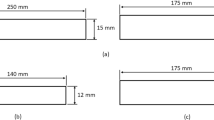

In this study, the crashworthiness characteristics of four cases including cylindrical hollow composite tubes, aluminum honeycomb-filled tubes, polyurethane foam-filled tubes, and polyurethane foam/aluminum honeycomb-filled cylindrical composite are experimentally investigated. The impact of honeycomb, polyurethane foam, combined polyurethane foam with honeycomb filling, and diameter and thickness of wall of cylindrical composites are also investigated. Then, the deformation mode, peak crushing force, mean crushing force (MCF), energy absorption (EA), and specific energy absorption of these composites possessing different structures are also explored. Furthermore, an analytical model for the crushing behavior of the cylindrical composite shell filled with foam and honeycomb materials under quasi-static load is provided. The analytical model which draws on the energy method is used to predict the MCF and crushing length during the collapse process. For this purpose, the diverse phenomena including shell bending, petal formation, circumferential delamination, friction, collapse of honeycomb cell walls, and deformation of foam are considered to determine the total internal energy relations during the crash process. These relations are used to make predictions on mean loads and total displacements during the collapse. The obtained results reveal a relatively good agreement between the analytical and experimental findings. The results showed that all novel cylindrical composite tubes filled with both polyurethane foam and aluminum honeycomb, in addition to increasing energy absorption compared to their counterparts, deform only in the stable mode of collapse (Mode I), which is a very important predictable deformation in terms of design.

Similar content being viewed by others

References

Xiao X (2009) Modeling energy absorption with a damage mechanics based composite material model. J Compos Mater 43(5):427–444. https://doi.org/10.1177/0021998308097686

Tomasz W (1983) Crushing analysis of metal honeycombs. Int J Impact Eng 1(2):157–174. https://doi.org/10.1016/0734-743X(83)90004-0

Weigang C, Tomasz W (2001) Relative merits of single-cell, multi-cell and foam-filled thin-walled structures in energy absorption. Thin-Walled Struct 39(4):287–306. https://doi.org/10.1016/S0263-8231(01)00006-4

Li K, Gao X-L, Wang J (2007) Dynamic crushing behavior of honeycomb structures with irregular cell shapes and non-uniform cell wall thickness. Int J Solids Struct 44(14–15):5003–5026. https://doi.org/10.1016/j.ijsolstr.2006.12.017

Mahmoudabadi MZ, Sadighi M (2009) A study on metal hexagonal honeycomb crushing under quasi-static loading. World Acad Sci Eng Technol 53:677–681

Nia AA, Sadeghi M (2010) The effects of foam filling on compressive response of hexagonal cell aluminum honeycombs under axial loading-experimental study. Mater Des 31(3):1216–1230. https://doi.org/10.1016/j.matdes.2009.09.030

Mahmoudabadi MZ, Sadighi M (2011) A study on the static and dynamic loading of the foam filled metal hexagonal honeycomb—theoretical and experimental. Mater Sci Eng A 530:333–343. https://doi.org/10.1016/j.msea.2011.09.093

Sadighi M, Salami SJ (2012) An investigation on low-velocity impact response of elastomeric & crushable foams. Central Eur J Eng 2(4):627–637. https://doi.org/10.2478/s13531-012-0026-0

Liu Q, Fu J, Wang J, Ma J, Chen H, Li Q et al (2017) Axial and lateral crushing responses of aluminum honeycombs filled with EPP foam. Compos B Eng 130:236–247. https://doi.org/10.1016/j.compositesb.2017.07.041

Zhang Y, Liu Q, He Z, Zong Z, Fang J (2019) Dynamic impact response of aluminum honeycombs filled with expanded polypropylene foam. Compos B Eng 156:17–27. https://doi.org/10.1016/j.compositesb.2018.08.043

Zarei H, Kröger M (2008) Optimum honeycomb filled crash absorber design. J Mater Des 29(1):193–204. https://doi.org/10.1016/j.matdes.2006.10.013

Santosa S, Wierzbicki T (1998) Crash behavior of box columns filled with aluminum honeycomb or foam. Comput Struct 68(4):343–367. https://doi.org/10.1016/S0045-7949(98)00067-4

Kılıçaslan C (2015) Numerical crushing analysis of aluminum foam-filled corrugated single-and double-circular tubes subjected to axial impact loading. Thin-Walled Struct 96:82–94. https://doi.org/10.1016/j.tws.2015.08.009

Hussein RD, Ruan D, Lu G, Guillow S, Yoon JW (2017) Crushing response of square aluminium tubes filled with polyurethane foam and aluminium honeycomb. Thin-Walled Struct 110:140–154. https://doi.org/10.1016/j.tws.2016.10.023

Yang F, Fan H, Meguid S (2019) Effect of foam-filling on collapse mode transition of thin-walled circular columns under axial compression: analytical, numerical and experimental studies. Int J Mech Sci 150:665–676. https://doi.org/10.1016/j.ijmecsci.2018.10.047

Zarei HR, Kröger M (2007) Crashworthiness optimization of empty and filled aluminum crash boxes. Int J Crashworthiness 12(3):255–264. https://doi.org/10.1080/13588260701441159

Mahbod M, Asgari M (2018) Energy absorption analysis of a novel foam-filled corrugated composite tube under axial and oblique loadings. Thin-walled Struct 129:58–73. https://doi.org/10.1016/j.tws.2018.03.023

Mamalis AG, Robinson M, Manolakos DE, Demosthenous GA, Ioannidis MB, Carruthers J (1997) Crashworthy capability of composite material structures. Compos Struct 37:109–134. https://doi.org/10.1016/S0263-8223(97)80005-0

Jacob GC, Fellers JF, Simunovic S, Starbuck JM (2002) Energy absorption in polymer composite materials for automotive crashworthiness. J Compos Mater 36:813–850. https://doi.org/10.1177/0021998302036007164

Mamalis A, Manolakos D, Demosthenous G, Ioannidis M (1997) Analytical modelling of the static and dynamic axial collapse of thin-walled fibreglass composite conical shells. Int J Impact Eng 19(5–6):477–492. https://doi.org/10.1016/S0734-743X(97)00007-9

Mahdi E, Mokhtar A, Asari N, Elfaki F, Abdullah E (2006) Nonlinear finite element analysis of axially crushed cotton fibre composite corrugated tubes. Compos Struct 75(1–4):39–48. https://doi.org/10.1016/j.compstruct.2006.04.057

Zarei H, Kröger M, Albertsen H (2008) An experimental and numerical crashworthiness investigation of thermoplastic composite crash boxes. Compos Struct 85(3):245–257. https://doi.org/10.1016/j.compstruct.2007.10.028

McGregor C, Vaziri R, Xiao X (2010) Finite element modelling of the progressive crushing of braided composite tubes under axial impact. Int J Impact Eng 37(6):72–662. https://doi.org/10.1016/j.ijimpeng.2009.09.005

Zhang Z, Liu S, Tang Z (2010) Crashworthiness investigation of kagome honeycomb sandwich cylindrical column under axial crushing loads. Thin-Walled Struct 48(1):9–18. https://doi.org/10.1016/j.tws.2009.08.002

Niknejad A, Liaghat G, Naeini HM, Behravesh A (2011) Theoretical and experimental studies of the instantaneous folding force of the polyurethane foam-filled square honeycombs. Mater Des 32(1):69–75. https://doi.org/10.1016/j.matdes.2010.06.033

Feraboli P, Wade B, Deleo F, Rassaian M, Higgins M, Byar A (2011) LS-DYNA MAT54 modeling of the axial crushing of a composite tape sinusoidal specimen. Compos A Appl Sci Manuf 42(11):1809–1825. https://doi.org/10.1016/j.compositesa.2011.08.004

Kathiresan M, Manisekar K, Manikandan V (2014) Crashworthiness analysis of glass fibre/epoxy laminated thin walled composite conical frusta under axial compression. Compos Struct 108:584–599. https://doi.org/10.1016/j.compstruct.2013.09.060

Boria S, Pettinari S, Giannoni F (2013) Theoretical analysis on the collapse mechanisms of thin-walled composite tubes. Compos Struct 103:43–49. https://doi.org/10.1016/j.compstruct.2013.03.020

Siromani D, Awerbuch J, Tan T-M (2014) Finite element modeling of the crushing behavior of thin-walled CFRP tubes under axial compression. Compos B Eng 64:50–58. https://doi.org/10.1016/j.compositesb.2014.04.008

Boria S, Belingardi G, Giannoni F (2014) A crashworthy problem on composite structures using a mathematical approach. Procedia Eng 88:125–132. https://doi.org/10.1016/j.proeng.2014.11.135

Hwang S-K, Hwang H-Y (2018) Theoretical approach for the mechanical behaviors of conical composite tubes considering fiber orientation errors under static loads. Compos Struct 183:84–95. https://doi.org/10.1016/j.compstruct.2017.01.042

Sun G, Li S, Li G, Li Q (2018) On crashing behaviors of aluminium/CFRP tubes subjected to axial and oblique loading: an experimental study. Compos B Eng 145:47–56. https://doi.org/10.1016/j.compositesb.2018.02.001

Sun GY, Li SF, Liu Q, Li GY, Li Q (2016) Experimental study on crashworthiness of empty/aluminum foam/honeycomb-filled CFRP tubes. Compos Struct 115:969–993. https://doi.org/10.1016/j.compstruct.2016.06.019

Gan N, Feng Y, Yin H, Wen G, Wang D, Huang X (2016) Quasi-static axial crushing experiment study of foam-filled CFRP and aluminum alloy thin-walled structures. Compos Struct 157:303–319. https://doi.org/10.1016/j.compstruct.2016.08.043

Elahi SA, Rouzegar J, Niknejad A, Assaee H (2017) Theoretical study of absorbed energy by empty and foam-filled composite tubes under lateral compression. Thin-Walled Struct 114:1–10. https://doi.org/10.1016/j.tws.2017.01.029

Zhang Y, Zong Z, Liu Q, Ma J, Wu Y, Li Q (2017) Static and dynamic crushing responses of CFRP sandwich panels filled with different reinforced materials. Mater Des 117:396–408. https://doi.org/10.1016/j.matdes.2017.01.010

Zhou J, Guan Z, Cantwell W (2018) The energy-absorbing behaviour of composite tube-reinforced foams. Compos B Eng 139:227–237. https://doi.org/10.1016/j.compositesb.2017.11.066

Meriç D, Gedikli H (2022) Multi-objective optimization of energy absorbing behavior of foam-filled hybrid composite tubes. Compos Struct 279:114771. https://doi.org/10.1016/j.compstruct.2021.114771

Yao R, Pang T, He S, Li Q, Zhang B, Sun G (2022) A bio-inspired foam-filled multi-cell structural configuration for energy absorption. Compos B Eng 238:109801. https://doi.org/10.1016/j.compositesb.2022.109801

Wang H, Wang W, Wang P, Jin F, Fan H (2021) Foam-filled lightweight braided-textile reinforced and nested tubular structures for energy absorption applications. Compos A Appl Sci Manuf 149:106569. https://doi.org/10.1016/j.compositesa.2021.106569

Yao S, Chen Z, Xu P, Li Z, Zhao Z (2021) Experimental and numerical study on the energy absorption of polyurethane foam-filled metal/composite hybrid structures. Metals 11(1):118. https://doi.org/10.3390/met11010118

Lykakos SS, Kostazos PK, Venetsanos OV, Manolakos DE (2021) Crashworthiness performance of aluminium, GFRP and hybrid aluminium/GFRP circular tubes under quasi-static and dynamic axial loading conditions: a comparative experimental study. Dynamics 1(1):22–48. https://doi.org/10.3390/dynamics1010004

Yang C, Chen Z, Yao S, Xu P, Li S, Alqahtani MS (2022) Parametric study on the crushing performance of a polyurethane foam-filled CFRP/Al composite sandwich structure. Polym Test 108:107515. https://doi.org/10.1016/j.polymertesting.2022.107515

Velmurugan R, Gupta NK, Solaimurugan S, Elayaperumal A (2004) The effect of stitching on FRP cylindrical shells under axial compression. Int J Impact Eng 30:923–938. https://doi.org/10.1016/j.ijimpeng.2004.04.007

ASTM D3039. Standard test method for tensile properties of polymer matrix composite materials

D1622/D1622M (2014) AI, Standard test method for apparent density of rigid cellular plastics, US

D1621 (2010) AI, standard test method for compressive properties of rigid cellular plastics, US

Mamalis AG, Manolakos DE, Demosthenous GA, Ioannidis MB (1998) Crashworthiness of composite thin-walled structural components. CRC Press

Farley GL (1992) Crushing characteristics of continuous fiber-reinforced composite tubes. J Compos Mater 26(1):37–50. https://doi.org/10.1177/002199839202600103

Hamada H, Ramakrishna S (1995) Scaling effects in the energy absorption of carbon-fiber/peek composite tubes. Compos Sci Technol 55:211–221. https://doi.org/10.1016/0266-3538(95)00081-X

Solaimurugan S, Velmurugan R (2007) Progressive crushing of stitched glass/polyester composite cylindrical shells. Compos Sci Technol 67(3–4):422–437. https://doi.org/10.1016/j.compscitech.2006.09.002

Morales JL, Nocedal J (2011) Remark on “algorithm 778: L-bfgs-b: fortran subroutines for large-scale bound constrained optimization.” ACM Trans Math Softw 38(1):7:1-7:4. https://doi.org/10.1145/2049662.2049669

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarkhosh, R., Farrokhabadi, A. & Zarei, H. Crashworthiness characteristics of composite cylindrical energy absorbers filled with honeycomb and foam under quasi-static load: experimental and analytical study. J Braz. Soc. Mech. Sci. Eng. 44, 346 (2022). https://doi.org/10.1007/s40430-022-03662-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-022-03662-0