Abstract

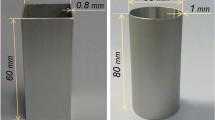

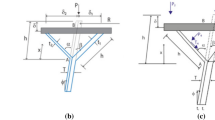

Thin-wall structures, particularly thin-walled tubes, play a critical role in load-bearing structures. Enhancing their ability to withstand crushing loads can significantly improve the overall damping efficiency of the system. Functionally graded thickness (FGT) is a promising approach for enhancing the load-bearing properties of thin-walled tubes by enabling control over material usage and localized deformation patterns within the structure. In this study, we proposed a novel theoretical model that analyzes the crushing behavior of hollow and foam-filled FGT thin-walled circular tubes by considering four primary failure mechanisms that contribute to energy dissipation: (1) bending of plastic hinges, (2) membrane stretching, (3) axial foam crushing, and (4) the interaction between foam and the tube's wall. We validated our model against experimental results from previous researchers and observed a good agreement. Additionally, we conduct a comprehensive study to examine the effects of various geometrical parameters, such as power-law functions and normalized wall thickness ratio, on the crushing behavior of FGT structures. Our results demonstrate the accuracy and reliability of our theoretical model and highlight the potential of FGT structures to enhance the performance of thin-walled tubes in a range of load-bearing applications.

Similar content being viewed by others

References

Ahmad Z, Thambiratnam DP (2009) Application of foam-filled conical tubes in enhancing the crashworthiness performance of vehicle protective structures. Int J Crashworthiness 14(4):349–363

Bisagni C (2002) Crashworthiness of helicopter subfloor structures. Int J Impact Eng 27(10):1067–1082

Wang Z et al (2017) Mechanical behavior of composited structure filled with tandem honeycombs. Compos B Eng 114:128–138

Wang Z et al (2016) Matching effect of honeycomb-filled thin-walled square tube—experiment and simulation. Compos Struct 157:494–505

Abramowicz W, Jones N (1984) Dynamic axial crushing of square tubes. Int J Impact Eng 2(2):179–208

Abramowicz W, Jones N (1984) Dynamic axial crushing of circular tubes. Int J Impact Eng 2(3):263–281

Abramowicz W, Jones N (1986) Dynamic progressive buckling of circular and square tubes. Int J Impact Eng 4(4):243–270

Yao R, Zhang B, Yin G, Zhao Z (2020) Energy absorption behaviors of foam-filled holed tube subjected to axial crushing: experimental and theoretical investigations. Mech Adv Mater Struct 28(24):501–2514

Niknejad A et al (2012) Prediction of the mean folding force during the axial compression in foam-filled grooved tubes by theoretical analysis. Mater Des 37:144–151

Abedi MM et al (2018) Foam-filled grooved tubes with circular cross section under axial compression: an experimental study. Iran J Sci Technol Trans Mech Eng 42(4):401–413

VimalKannan I, Rajkumar R (2020) Deformation and energy absorption analysis of simple and multi-cell thin-walled tubes under quasi-static axial crushing. Int J Crashworthiness 25(2):121–130

Jin M et al (2022) Improving the crashworthiness of bio-inspired multi-cell thin-walled tubes under axial loading: experimental, numerical, and theoretical studies. Thin-Walled Struct 177:109415

Nagel G, Thambiratnam D (2004) A numerical study on the impact response and energy absorption of tapered thin-walled tubes. Int J Mech Sci 46(2):201–216

Reid S, Reddy T (1986) Static and dynamic crushing of tapered sheet metal tubes of rectangular cross-section. Int J Mech Sci 28(9):623–637

Mamalis A, Johnson W (1983) The quasi-static crumpling of thin-walled circular cylinders and frusta under axial compression. Int J Mech Sci 25(9–10):713–732

Guillow S, Lu G, Grzebieta R (2001) Quasi-static axial compression of thin-walled circular aluminium tubes. Int J Mech Sci 43(9):2103–2123

Ebrahimi S, Vahdatazad N, Liaghat G (2018) Experimental characterization of the energy absorption of functionally graded foam filled tubes under axial crushing loads. J Theor Appl Mech 48(1):76

Hong W et al (2013) Quasi-static axial compression of triangular steel tubes. Thin-Walled Struct 62:10–17

Abedi MM et al (2012) Theoretical and experimental study on empty and foam-filled columns with square and rectangular cross section under axial compression. Int J Mech Sci 65(1):134–146

Gao Z et al (2023) Axial compression of multi-cell hexagonal tubes with novel hierarchical architectures: numerical and theoretical analyses. Compos Struct 318:117079

Yang F, Deng X, Wang C (2023) Analysis of energy absorption characteristics of a sinusoidal corrugated filled tube. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2023.2244961

Liu W et al (2016) Dynamic performances of thin-walled tubes with star-shaped cross section under axial impact. Thin-Walled Struct 100:25–37

de Lemos Coutinho L et al (2022) Energy absorption of CFRP composite thin-walled tubes with PVC foam-filled cores. Innov Infrastruct Solut 7(2):168

Yang H, Lei H, Lu G (2021) Crashworthiness of circular fiber reinforced plastic tubes filled with composite skeletons/aluminum foam under drop-weight impact loading. Thin-Walled Struct 160:107380

AlGalib D, Limam A (2004) Experimental and numerical investigation of static and dynamic axial crushing of circular aluminum tubes. Thin-Walled Struct 42(8):1103–1137

Simhachalam B, Srinivas K, Rao CL (2014) Energy absorption characteristics of aluminium alloy AA7XXX and AA6061 tubes subjected to static and dynamic axial load. Int J Crashworthiness 19(2):139–152

Marzbanrad J, Ebrahimi MR (2011) Multi-objective optimization of aluminum hollow tubes for vehicle crash energy absorption using a genetic algorithm and neural networks. Thin-Walled Struct 49(12):1605–1615

Wang Z, Liu J (2018) Mechanical performance of honeycomb filled with circular CFRP tubes. Compos B Eng 135:232–241

Liu J, Wang Z, Hui D (2018) Blast resistance and parametric study of sandwich structure consisting of honeycomb core filled with circular metallic tubes. Compos B Eng 145:261–269

Liu W et al (2018) Crashworthiness analysis of cylindrical tubes filled with conventional and negative Poisson’s ratio foams. Thin-Walled Struct 131:297–308

Meguid S, Cheon S, El-Abbasi N (2002) FE modelling of deformation localization in metallic foams. Finite Elem Anal Des 38(7):631–643

Yang F, Fan H, Meguid S (2019) Effect of foam-filling on collapse mode transition of thin-walled circular columns under axial compression: analytical, numerical and experimental studies. Int J Mech Sci 150:665–676

Hanssen AG, Langseth M, Hopperstad OS (2000) Static and dynamic crushing of square aluminium extrusions with aluminium foam filler. Int J Impact Eng 24(4):347–383

Hanssen AG, Langseth M, Hopperstad OS (2000) Static and dynamic crushing of circular aluminium extrusions with aluminium foam filler. Int J Impact Eng 24(5):475–507

Yang F, Meguid S, Hamouda A (2018) Kinematically admissible folding mechanisms for the progressive collapse of foam filled conical frusta. Int J Mech Mater Des 14(1):105–126

Pan F, Zhu P, Zhang Y (2010) Metamodel-based lightweight design of B-pillar with TWB structure via support vector regression. Comput Struct 88(1–2):36–44

Xu F et al (2013) Crashworthiness design of multi-component tailor-welded blank (TWB) structures. Struct Multidiscip Optim 48(3):653–667

Xu P et al (2016) Crash performance and multi-objective optimization of a gradual energy-absorbing structure for subway vehicles. Int J Mech Sci 107:1–12

Pan F, Zhu P (2011) Lightweight design of vehicle front–end structure: contributions of multiple surrogates. Int J Veh Des 57(2–3):124–147

Meyer A, Wietbrock B, Hirt G (2008) Increasing of the drawing depth using tailor rolled blanks—numerical and experimental analysis. Int J Mach Tools Manuf 48(5):522–531

Chuang C et al (2008) Multidisciplinary design optimization on vehicle tailor rolled blank design. Struct Multidiscip Optim 35(6):551–560

Urban M et al (2006) Numerical research and optimisation of high pressure sheet metal forming of tailor rolled blanks. J Mater Process Technol 177(1–3):360–363

Sun G et al (2014) Crashing analysis and multiobjective optimization for thin-walled structures with functionally graded thickness. Int J Impact Eng 64:62–74

Li G et al (2015) A comparative study on thin-walled structures with functionally graded thickness (FGT) and tapered tubes withstanding oblique impact loading. Int J Impact Eng 77:68–83

Zhang X, Zhang H, Wen Z (2015) Axial crushing of tapered circular tubes with graded thickness. Int J Mech Sci 92:12–23

Yao S, Xing Y, Zhao K (2017) Crashworthiness analysis and multiobjective optimization for circular tubes with functionally graded thickness under multiple loading angles. Adv Mech Eng 9(4):1687814017696660

Baykasoglu C, Cetin MT (2015) Energy absorption of circular aluminium tubes with functionally graded thickness under axial impact loading. Int J Crashworthiness 20(1):95–106

Sun G et al (2017) Energy absorption mechanics for variable thickness thin-walled structures. Thin-Walled Struct 118:214–228

Wang P et al (2020) Energy absorption of thin-walled circular tubes with gradient thickness under oblique loads. Proc Inst Mech Eng C J Mech Eng Sci 234(16):3207–3220

Zhang H, Gao Z, Ruan D (2023) Square tubes with graded wall thickness under oblique crushing. Thin-Walled Struct 183:110429

Sun G et al (2010) Crashworthiness design for functionally graded foam-filled thin-walled structures. Mater Sci Eng A 527(7–8):1911–1919

Guler MA et al (2010) The effect of geometrical parameters on the energy absorption characteristics of thin-walled structures under axial impact loading. Int J Crashworthiness 15(4):377–390

Wierzbicki T et al (1992) Alexander revisited—a two folding elements model of progressive crushing of tubes. Int J Solids Struct 29(24):3269–3288

Abramowicz W, Wierzbicki T (1988) Axial crushing of foam-filled columns. Int J Mech Sci 30(3–4):263–271

Meguid S, Yang F, Verberne P (2015) Progressive collapse of foam-filled conical frustum using kinematically admissible mechanism. Int J Impact Eng 82:25–35

Rahi A (2019) Experimental and crash-worthiness optimization of end-capped conical tubes under quasi-static and dynamic loading. Mech Adv Mater Struct 26(17):1437–1446

Abramowicz W (1983) The effective crushing distance in axially compressed thin-walled metal columns. Int J Impact Eng 1(3):309–317

Funding

No funding was received to assist with the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Technical Editor: João Marciano Laredo dos Reis.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barzigar, S.S., Ahmadi, H., Liaghat, G. et al. Crashworthiness analysis of empty and foam-filled circular tubes with functionally graded thickness. J Braz. Soc. Mech. Sci. Eng. 46, 205 (2024). https://doi.org/10.1007/s40430-024-04781-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-024-04781-6