Abstract

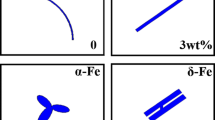

The evolution of the 3D Fe-rich phases of Al–7.0Si–1.2Fe alloys with different Mn contents was visualized and characterized using synchrotron X-ray computed tomography, and the effect of Fe-rich phases with typical morphologies on the fracture behavior during tensile testing was analyzed. The results showed that the Fe-rich phase changed from platelet-like β-Al5FeSi into α-Al15(FeMn)3Si2 with various morphologies after the addition of Mn. The Mn addition not only significantly reduced the volume fraction, equivalent diameter and interconnectivity of the Fe-rich phase but also greatly increased the sphericity, surface thickness, and distribution of the mean curvature and surface thickness. Furthermore, the equivalent diameter of α-Al15(FeMn)3Si2 had an inverse exponential function relationship with its sphericity. The 3D morphology of α-Al15(FeMn)3Si2 can be summarized as massive and regular polyhedrons, hollow and regular polyhedrons, and multibranched polyhedrons. The fraction of the different 3D morphologies in each alloy is related to the Mn content, where excess Mn increased the number and volume fraction of the large Fe-rich particles with a low sphericity. The ductility of each alloy was significantly improved by the addition of Mn but gradually decreased when the Mn/Fe ratio exceeded 1.2. The increase in large α-Al15(MnFe)3Si2 with a low sphericity was the main reason for the decreased ductility of alloys with a high Mn content.

Similar content being viewed by others

References

N. Ding, F. Gao, Z. Wang, X. Gong, Z. Nie, Procedia Eng. 27, 465 (2012)

L. Hurtalová, E. Tillová, M. Chalupová, E. Ďuriníková, Mach. Technol. Mater. 6, 11 (2012)

J.A. Taylor, Procedia Mater. Sci. 1, 19 (2012)

L.F. Zhang, J.W. Gao, L.N.W. Damoah, D.G. Robertson, Min. Proc. Ext. Met. Rev. 33, 99 (2012)

Z. Li, N. Limodin, A. Tandjaoui, P. Quaegebeur, J.F. Witz, D. Balloy, Eng. Fract. Mech. 183, 94 (2017)

I. Bacaicoa, M. Luetje, M. Wicke, A. Geisert, F. Zeismann, M. Fehlbier, A. Brueckner-Foit, Procedia Struct. Integr. 2, 2269 (2016)

M.A. Moustafa, J. Mater. Process. Technol. 209, 605 (2009)

C.M. Dinnis, J.A. Taylor, A.K. Dahle, Metall. Mater. Trans. A 37, 3283 (2006)

S.G. Shabestari, Mater. Sci. Eng. A 383, 289 (2004)

D.F. Song, S.C. Wang, K.H. Zheng, Chin. J. Nonferr. Metal. 25, 1832 (2015)

H. Becker, T. Bergh, P.E. Vullum, A. Leineweber, Y. Li, Materialia 780, 100198 (2019)

J.Y. Hwang, H.W. Doty, M.J. Kaufman, Mater. Sci. Eng. A 488, 496 (2008)

D. Bösch, S. Pogatscher, M. Hummel, W. Fragner, P.J. Uggowitzer, M. Göken, H.W. Höppel, Metall. Mater. Tran. A 46, 1035 (2015)

X. Cao, J. Campbell, Metall. Mater. Tran. A 35, 1425 (2004)

A. Fabrizia, G. Timelli, IOP Conf. Ser. Mater. Sci. Eng. 117, 12 (2016)

G. Timelli, S. Capuzzi, A. Fabrizi, J. Therm. Anal. Nal. Calorim. 123, 249 (2016)

Z.Q. Qiu, X.C. Meng, Q.H.X.S. Zeng, X.X. Rao, Y. Ding, L. Luo, Y. Liu, Acta Metall. Sin. Engl. Lett. 31, 629 (2018)

X. Cao, J. Campbell, Int. J. Cast Metal Res. 17, 1 (2004)

Z. Xu, T. Li, Y. Zhou, J. Mater. Sci. 38, 4557 (2003)

S.W. Kim, U.H. Im, H.C. Cha, S.H. Kim, J.E. Jang, K.Y. Kim, China Foundry 10, 112 (2013)

H.L.D. Moraes, J.R.D. Oliveira, D.C.R. Espinosa, J.A.S. Tenório, Mater. Trans. 47, 1731 (2006)

D.F. Song, Y.L. Zhao, Z. Wang, Y.W. Jia, H.L. Huang, D.T. Zhang, W.W. Zhang, J. Mater. Res. 36, 1357 (2021)

D.F. Song, S.C. Wang, Y.L. Zhao, S.H. Liu, Y. Du, Y.H. Kang, Z. Wang, W.W. Zhang, Trans. Nonferrous Metals Soc. China 30, 1 (2020)

C.M. Dinnis, J.A. Taylor, A.K. Dahle, Scr. Mater. 53, 955 (2005)

M. Timpel, N. Wanderka, R. Grothausmann, J. Banhart, J. Alloys Compd. 558, 18 (2013)

J.M. Yu, N. Wanderka, G. Miehe, J. Banhart, Intermetallics 72, 53 (2016)

Z. Li, N. Limodin, A. Tandjaoui, P. Quaegebeur, P. Osmond, D. Balloy, Mater. Sci. Eng. A 689, 286 (2017)

C. Hu, W.F. Luo, H.D. Zhao, China Foundry 14, 379 (2017)

Z.Y. Ding, N.F. Zhang, L. Yu, W.Q. Lu, J.G. Li, Q.D. Hu, Acta Metall. Sin. Engl. Lett. 34, 45 (2021)

Y. Zhao, D. Song, L. Bo, C. Zhang, W. Zhang, Mater. Charact. 153, 354 (2019)

X.Y. Jiao, C.F. Liu, Z.P. Guo, G.D. Tong, S.L. Ma, Y. Bi, Y.F. Zhang, S.M. Xiong, J. Mater. Sci. Technol. 51, 54 (2020)

J.M. Yu, N. Wanderka, A. Rack, E. Raudin, E. Boller, H. Markötter, A. Manzoni, F. Vogel, T. Arlt, I. Manke, J. Banhart, Acta. Mater. 129, 194 (2017)

C. Puncreobutr, P.D. Lee, K.M. Kareh, T. Connolley, A.B. Phillion, Acta. Mater. 68, 42 (2014)

N.F. Zhang, Q.D. Hu, F. Yang, W.Q. Lu, Z.Y. Ding, S. Cao, L. Yu, X. Ge, J.G. Li, Metall. Mater. Trans. A 51, 2711 (2020)

Y. Zhao, W. Zhi, C. Zhang, W. Zhang, J. Alloys Compd. 777, 1054 (2019)

Y. Zhao, W. Du, B. Koe, T. Connolley, S. Irvine, P.K. Allan, C.M. Schlepütz, W. Zhang, F. Wang, D.G. Eskin, Scr. Mater. 146, 321 (2018)

Y. Zhao, W. Zhang, D. Song, B. Lin, F. Shen, D. Zheng, X. Xie, Z. Sun, Y. Fu, R. Li, J. Mater. Sci. Technol. 80, 84 (2021)

INFN Trieste, PITRE, http://webint.ts.infn.it/en/research/exp/beats2/pitre.html (2013)

FEI, Amira-Avizo 3D Software. http://www.fei.com/software/avizo3d/ (2017)

T. Gao, Y. Wu, C. Li, X. Liu, Mater. Lett. 110, 191 (2013)

J. Wang, P.D. Lee, R.W. Hamilton, M. Li, J. Allison, Scr. Mater. 60, 516 (2009)

S. Terzi, J.A. Taylor, Y.H. Cho, L. Salvo, M. Suéry, E. Boller, A.K. Dahle, Acta. Mater. 58, 5370 (2010)

M.H. Mulazimoglu, A. Zaluska, J.E. Gruzleski, F. Paray, Metall. Mater. Trans. A 27, 929 (1996)

S. Seifeddine, S. Johansson, L.S. Ingvar, Mater. Sci. Eng. A 490, 385 (2008)

X. Lan, K. Li, F. Wang, M. Yang, S. Liu, J. Wang, Y. Du, J. Alloys Compd. 784, 68 (2019)

J. Yi, Y. Gao, P. Lee, T. Lindley, Mater. Sci. Eng. A 386, 396 (2004)

A. Bjurenstedt, E. Ghassemali, S. Seifeddine, A. Dahle, Mater. Sci. Eng. A 756, 502 (2019)

L. Ceschini, A. Morri, A. Morri, A. Gamberini, S. Messieri, Mater. Des. 30, 4525 (2009)

L. Wang, N. Limodin, A.E. Bartali, J.F. Witz, J.Y. Buffiere, E. Charkaluk, Metall. Mater. Trans. A 51, 3843 (2020)

Acknowledgements

The work was financially supported by the National Natural Science Foundation of China (No. 52074131), the Foundation and Applied Foundation Program of Guangdong Province (No. 2020B1515120065), the Key-Area Research and Development Program of Guangdong Province (No. 2020B010186002), and the Science and Technology Plan Program of Guangdong Province (Nos. 2015B090926013, 2019B090905009). We would also like to thank the WL13W1 beamline of Shanghai Synchrotron Radiation Facility, SSRF (proposal number 2018-SSRF-PT-006299, 2020-SSRF-PT-011937), for providing synchrotron radiation beamtime.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Available online at http://link.springer.com/journal/40195.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (AVI 4368 kb)

Supplementary file2 (AVI 4596 kb)

Supplementary file3 (AVI 4543 kb)

Rights and permissions

About this article

Cite this article

Song, DF., Zhao, YL., Wang, Z. et al. 3D Fe-Rich Phases Evolution and Its Effects on the Fracture Behavior of Al–7.0Si–1.2Fe Alloys by Mn Neutralization. Acta Metall. Sin. (Engl. Lett.) 35, 163–175 (2022). https://doi.org/10.1007/s40195-021-01299-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-021-01299-x