Abstract

The strategies that have been developed to improve the utility of poly(lactic acid) (PLA) in packaging materials were examined. This study has focused on two potential solutions: the addition of a plasticizer and the use of nanoclays under optimal conditions. Triacetin (TA) as a plasticizer (10 and 20% by wt) and modified nanoclays (C30B and C20A) as reinforcing agents (1 and 3% by wt) were incorporated into the PLA matrix. The PLA-based films were prepared through solvent-casting method. The nanocomposite films] characteristics including tensile properties, moisture content (MC), water vapor permeability (WVP), swelling, stability, FTIR spectra, optical properties, thermogravimetric analysis (TGA), and X-ray diffraction (XRD) were investigated. The results demonstrated that both TA and nanoclays led to an increase in the elongation-at-break (Eab) and tensile strength (TS) of PLA films. In addition, the films with TA of 20% (by wt) showed the highest Eab (78.5%). By adding nanoclays, a decrease in WVP, stability, and light transmission, and an increase in MC, swelling, and opacity of the PLA-based films were observed. PLA films with 3% (by wt) of C20A and 10% (by wt) of TA contents showed the lowest WVP (1.06 × 10–10 g/m.s Pa). Furthermore, the film containing 3% (by wt) of C30B and 20% (by wt) of TA displayed the highest MC (19.4%). XRD analysis approved that an intercalated conformation was created in the nanocomposites during the incorporation process. The TGA showed a slight improvement in thermal stability of the nanocomposite films compared to a neat PLA film. This study confirmed that the PLA-based films prepared by incorporating an optimal amount of TA and the nanoclays (C20A and C30B) into the PLA matrix are promising materials for food packaging applications.

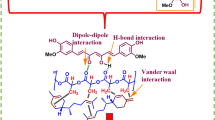

Graphical abstract

Similar content being viewed by others

Data availability

The data that support the findings of this study are presented in the paper.

References

Reddy TRK, Kim HJ, Park JW (2016). In: Méndez-Vilas A, Solano A (eds) Bio-nanocomposite properties and its food packaging applications. Formatex Research Center, Spain

Turan D, Gunes G, Kilic A (2018) Perspectives of bio-nanocomposites for food packaging applications. In: Jawaid M, Swain SK (eds) Bionanocomposites for Packaging Applications. Springer, Cham, Switzerland

Aslam A, Zahoor T, Khan MR, Khaliq A, Nadeem M, Sagheer A, Chugtai MFJ, Sajid MW (2019) Studying the influence of packaging materials and storage on the physiochemical and microbial characteristics of black plum (Syzygium cumini) jam. J Food Proc Preserv 43:e13941

Ebrahimifar M, Taherimehr M (2021) Evaluation of in-vitro drug release of polyvinylcyclohexane carbonate as a CO2-derived degradable polymer blended with PLA and PCL as drug carriers. J Drug Deliv Sci Technol 63:102491

Sheydai A, Nikzad M, Peyravi M (2022) Improvement in mechanical and physical properties of starch-based films provided by cellulose nanocrystals extracted from rice straw. J Thermoplast Compos Mater. https://doi.org/10.1177/08927057221128197

Aminitabar A, Nikzad M, Taherimehr M (2021) Tuning the gas sensing properties of C20 towards H2S and O3 by doping and external electric field. Russ J Inorg Chem 66:2105–2115

Taherimehr M, Pescarmona PP (2014) Green polycarbonates prepared by the copolymerization of CO2 with epoxides. J Appl Polym Sci 131:41141

Taherimehr M, Al-Amsyar SM, Whiteoak CJ, Kleij AW, Pescarmona PP (2013) High activity and switchable selectivity in the synthesis of cyclic and polymeric cyclohexene carbonates with iron amino triphenolate catalysts. Green Chem 15:3083–3090

Yousefnia Pasha H, Mohtasebi SS, Tabatabaeekoloor R, Taherimehr M, Javadi A, Soltani Firouz M (2021) Preparation and characterization of the plasticized polylactic acid films produced by the solvent-casting method for food packaging applications. J Food Proc Preserv 45:e16089

Taherimehr M, Bagheri R, Taherimehr M (2021) In-vitro evaluation of thermoplastic starch/beta-tricalcium phosphate nano-biocomposite in bone tissue engineering. Ceram Int 47:15458–15463

Solati M, Saeidi A, Ghasemi I (2019) The effect of graphene nanoplatelets on dynamic properties, crystallization, and morphology of a biodegradable blend of poly(lactic acid)/thermoplastic starch. Iran Polym J 28:649–658

Mangaraj S, Yadav A, Bal LM, Dash S, Mahanti NK (2019) Application of biodegradable polymers in food packaging industry: a comprehensive review. J Packag Technol Res 3:77–96

Zhong Y, Godwin P, Jin Y, Xiao H (2020) Biodegradable polymers and green-based antimicrobial packaging materials: a mini-review. Adv Ind Eng Polym Res 3:27–35

Rhim J-W, Park H-M, Ha C-S (2013) Bio-nanocomposites for food packaging applications. Prog Polym Sci 38:1629–1652

Taherimehr M, Yousefnia Pasha H, Tabatabaeekoloor R, Pesaranhajiabbas E (2021) Trends and challenges of biopolymer-based nanocomposites in food packaging. Compr Rev Food Sci Food Saf 20:5321–5344

Chong WJ, Shen S, Li Y, Trinchi A, Pejak D, Kyratzis I, Sola A, Wen C (2022) Additive manufacturing of antibacterial PLA-ZnO nanocomposites: benefits, limitations and open challenges. J Mater Sci Technol 111:120–151

Kalendova A, Smotek J, Stloukal P, Kracalik M, Slouf M, Laske S (2019) Transport properties of poly(lactic acid)/clay nanocomposites. Polym Eng Sci 59:2498–2501

Lim JH, Kim JA, Ko JA, Park HJ (2015) Preparation and characterization of composites based on polylactic acid and beeswax with improved water vapor barrier properties. J Food Sci 80:E2471–E2477

Wang L-F, Rhim J-W, Hong S-I (2016) Preparation of poly(lactide)/poly(butylene adipate-co-terephthalate) blend films using a solvent casting method and their food packaging application. LWT Food Sci Technol 68:454–461

Chieng BW, Ibrahim NA, Yunus WMZW, Hussein MZ (2014) Poly(lactic acid)/poly(ethylene glycol) polymer nanocomposites: effects of graphene nanoplatelets. Polymers 6:93–104

Babapour H, Jalali H, Mohammadi Nafchi A (2021) The synergistic effects of zinc oxide nanoparticles and fennel essential oil on physicochemical, mechanical, and antibacterial properties of potato starch films. Food Sci Nut 9:3893–3905

Hou X, Yao S, Wang Z, Fang C, Li T (2021) Enhancement of the mechanical properties of polylactic acid/basalt fiber composites via in-situ assembling silica nanospheres on the interface. J Mater Sci Technol 84:182–190

Arrieta M, de Dicastillo CL, Garrido L, Roa K, Galotto MJ (2018) Electrospun PVA fibers loaded with antioxidant fillers extracted from Durvillaea antarctica algae and their effect on plasticized PLA bionanocomposites. Eur Polym J 103:145–157

Fadl S, Madkour T (2019) Novel nood packaging based on naturally-plasticized poly(lactic acid) for enhanced nutritional storage. CPQ Nut 1–14

Courgneau C, Domenek S, Guinault A, Avérous L, Ducruet V (2011) Analysis of the structure-properties relationships of different multiphase systems based on plasticized poly(lactic acid). J Polym Environ 19:362–371

Ozdemir E, Hacaloglu J (2017) Characterizations of PLA-PEG blends involving organically modified montmorillonite. J Anal Appl Pyrol 127:343–349

Zhuang W, Liu J, Zhang JH, Hu BX, Shen J (2009) Preparation, characterization, and properties of TiO2/PLA nanocomposites by in situ polymerization. Polym Compos 30:1074–1080

Swaroop C, Shukla M (2018) Nano-magnesium oxide reinforced polylactic acid biofilms for food packaging applications. Int J Biolog Macromol 113:729–736

Kim SRB, Choi Y-G, Kim J-Y, Lim S-T (2015) Improvement of water solubility and humidity stability of tapioca starch film by incorporating various gums. LWT Food Sci Technol 64:475–482

Llorens A, Lloret E, Picouet PA, Trbojevich R, Fernandez A (2012) Metallic-based micro and nanocomposites in food contact materials and active food packaging. Trends Food Sci Technol 24:19–29

Dimitry O, Abdeen Z, Ismail E, Saad A (2011) Studies of particle dispersion in elastomeric polyurethane/organically modified montmorillonite nanocomposites. Int J Green Nanotechnol 3:197–212

Robledo-Ortíz J, Martín del Campo A, López-Naranjo E, Arellano M, Jasso-Gastinel C, González-Núñez R, Pérez-Fonseca A (2019) Effect of low nanoclay content on the physico-mechanical properties of poly(lactic acid) nanocomposites. Polym Polym Compos 27:43–54

Rhim J-W, Hong S-I, Ha C-S (2009) Tensile, water vapor barrier and antimicrobial properties of PLA/nanoclay composite films. LWT Food Sci Technol 42:612–617

Dadashi S, Mousavi SM, Emam-Djomeh Z, Oromiehie A (2014) Functional properties of biodegradable nanocomposites from poly lactic acid (PLA). Int J Nanosci Nanotech 10:245–256

Tang Z, Fan F, Chu Z, Fan C, Qin Y (2020) Barrier properties and characterizations of poly(lactic Acid)/ZnO nanocomposites. Molecules 25:1310

Risyon NP, Othman SH, Basha RK, Talib RA (2016) Effect of halloysite nanoclay concentration and addition of glycerol on mechanical properties of bionanocomposite films. Polym Polym Compos 24:795–802

Yang P, Li H, Liu Q, Dong H, Duan Y, Zhang J (2018) Plasticization of poly(lactic) acid film as a potential coating material. IOP Conf Ser: Earth Environ Sci, IOP Publishing

ASTM (2002) Standard test method for tensile properties of thin plastic sheeting D882–02. Am Soc Test Mater, Philadelphia, PA

Fernandes SS, Romani VP, da Silva FG, Martins V (2020) Chia seeds to develop new biodegradable polymers for food packaging: Properties and biodegradability. Polym Eng Sci 60:2214–2223

Chen J, Wu A, Yang M, Ge Y, Pristijono P, Li J, Xu B, Mi H (2021) Characterization of sodium alginate-based films incorporated with thymol for fresh-cut apple packaging. Food Control 126:108063

Yang S, Li H, Sun H (2018) Preparation of gelatin-based films modified with nanocrystalline cellulose. Iran Polym J 27:645–652

Ajayi O, Obadina A, Idowu M, Adegunwa M, Kajihausa O, Sanni L, Asagbra Y, Ashiru B, Tomlins K (2015) Effect of packaging materials on the chemical composition and microbiological quality of edible mushroom (Pleurotus ostreatus) grown on cassava peels. Food Sci Nut 3:284–291

Wang L, Wang Q, Tong J, Zhou J (2017) Physicochemical properties of chitosan films incorporated with honeysuckle flower extract for active food packaging. J Food Proc Eng 40:e12305

Finke B, Schröder K, Ohl A (2009) Structure retention and water stability of microwave plasma polymerized films from allylamine and acrylic acid. Plasma Proc Polym 6:S70–S74

ASTM (2016) Standard test method for Water Vapor Transmission of Materials E96–95. Am Soc Test Mater, Philadelphia, PA

Casariego A, Souza BWS, Cerqueira MA, Teixeira JA, Cruz L, Díaz R, Vicente AA (2009) Chitosan/clay films’ properties as affected by biopolymer and clay micro/nanoparticles’ concentrations. Food Hydrocol 23:1895–1902

Zhao R, Guan W, Zheng P, Tian F, Zhang Z, Sun Z, Cai L (2022) Development of edible composite film based on chitosan nanoparticles and their application in packaging of fresh red sea bream fillets. Food Control 132:108545

Mohd Aris ZF, Bavishi V, Sharma R, Nagarajan R (2019) Barrier properties and abrasion resistance of biopolymer-based coatings on biodegradable poly(lactic acid) films. Polym Eng Sci 59:1874–1881

Aadil KR, Jha H (2016) Physico-chemical properties of lignin–alginate based films in the presence of different plasticizers. Iran Polym J 25:661–670

Arrieta M, Peponi L, López D, Fernández-García M (2018) Recovery of yerba mate (Ilex paraguariensis) residue for the development of PLA-based bionanocomposite films. Ind Crops Prod 111:317–328

Martins JT, Cerqueira MA, Vicente AA (2012) Influence of α-tocopherol on physicochemical properties of chitosan-based films. Food Hydrocol 27:220–227

Ahmed S, Ikram S (2016) Chitosan and gelatin based biodegradable packaging films with UV-light protection. J Photochem Photobiol B 163:115–124

Shankar S, Rhim JW (2017) Preparation and characterization of agar/lignin/silver nanoparticles composite films with ultraviolet light barrier and antibacterial properties. Food Hydrocol 71:76–84

Cui R, Yan J, Cao J, Qin Y, Yuan M, Li L (2020) Release properties of cinnamaldehyde loaded by montmorillonite in chitosan-based antibacterial food packaging. Int J Food Sci Technol 56:3670–3681

Sodeifian G, Nikooamal HR, Yousefi AA (2012) Molecular dynamics study of epoxy/clay nanocomposites: rheology and molecular confinement. J Polym Res 19:1–12

Shakour N, Khoshkhoo Z, Akhondzadeh Basti A, Khanjari A, Mahasti Shotorbani P (2021) Investigating the properties of PLA-nanochitosan composite films containing Ziziphora Clinopodioides essential oil and their impacts on oxidative spoilage of Oncorhynchus mykiss fillets. Food Sci Nut 9:1299–1311

Fang C, Liu X, Yu R, Liu P, Lei W (2014) Preparation and properties of asphalt modified with a composite composed of waste package poly(vinyl chloride) and organic montmorillonite. J Mater Sci Technol 30:1304–1310

ASTM (2014) Standard test method for compositional analysis by thermogravimetry E1131-08. Am Soc Test Mater, Philadelphia, PA

Kadam AA, Singh S, Gaikwad KK (2021) Chitosan based antioxidant films incorporated with pine needles (Cedrus deodara) extract for active food packaging applications. Food Control 124:107877

Luzi F, Dominici F, Armentano I, Fortunati E, Burgos N, Fiori S, Jiménez A, Kenny JM, Torre L (2019) Combined effect of cellulose nanocrystals, carvacrol and oligomeric lactic acid in PLA_PHB polymeric films. Carbohydr Polym 223:115131

Lee KY, Lee JH, Yang HJ, Song KB (2016) Production and characterisation of skate skin gelatin films incorporated with thyme essential oil and their application in chicken tenderloin packaging. Int J Food Sci Technol 51:1465–1472

Kumar S, Shukla A, Baul PP, Mitra A, Halder D (2018) Biodegradable hybrid nanocomposites of chitosan/gelatin and silver nanoparticles for active food packaging applications. Food Packag Shelf Life 16:178–184

Correa JP, Bacigalupe A, Maggi J, Eisenberg P (2016) Biodegradable PLA/PBAT/clay nanocomposites: morphological, rheological and thermomechanical behavior. J Renew Mater 4:258–265

Bijarimi M, Ahmad S, Rasid R, Khushairi MA, Zakir M (2016) Poly(lactic acid)/poly(ethylene glycol) blends: Mechanical, thermal and morphological properties. In 6th Int Adv Appl Phys Mater Sci Cong Exhib, Am Instit Phys (AIP)

Müller CM, Yamashita F, Laurindo JB (2008) Evaluation of the effects of glycerol and sorbitol concentration and water activity on the water barrier properties of cassava starch films through a solubility approach. Carbohydr Polym 72:82–87

Ozkoc G, Kemaloglu S (2009) Morphology, biodegradability, mechanical, and thermal properties of nanocomposite films based on PLA and plasticized PLA. J Appl Polym Sci 114:2481–2487

Mohapatra AK, Mohanty S, Nayak S (2014) Effect of PEG on PLA/PEG blend and its nanocomposites: a study of thermo-mechanical and morphological characterization. Polym Compos 35:283–293

Aguirre A, Borneo R, León AE (2013) Properties of triticale protein films and their relation to plasticizing–antiplasticizing effects of glycerol and sorbitol. Ind Crop Prod 50:297–303

Alves VD, Mali S, Beléia A, Grossmann MVE (2007) Effect of glycerol and amylose enrichment on cassava starch film properties. J Food Eng 78:941–946

Darie RN, Pâslaru E, Sdrobis A, Pricope GM, Hitruc GE, Poiata A, Baklavaridis A, Vasile C (2014) Effect of nanoclay hydrophilicity on the poly(lactic acid)/clay nanocomposites properties. Ind Eng Chem Res 53:7877–7890

Aguiar RA, Rodrigues JS, Gonçalves MP, Borsagli FG (2022) Ecofriendly bio-packing based on sugarcane bagasse fiber for potential application in agroindustry. Sustain Chem Eng 3:66–74

Souza AC, Benze R, Ferrão ES, Ditchfield C, Coelho ACV, Tadini CC (2012) Cassava starch biodegradable films: influence of glycerol and clay nanoparticles content on tensile and barrier properties and glass transition temperature. LWT Food Sci Technol 46:110–117

Lizundia E, Vilas JL, Sangroniz A, Etxeberria A (2017) Light and gas barrier properties of PLLA/metallic nanoparticles composite films. Eur Polym J 91:10–20

Ediyilyam S, George B, Shankar SS, Dennise TT, Wacławek S, Černík M, Padil VV (2021) Chitosan/gelatin/silver nanoparticles composites films for biodegradable food packaging applications. Polymers 13:1680

Sanyang ML, Sapuan SM, Jawaid M, Ishak MR, Sahari J (2016) Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (Arenga pinnata) starch for food packaging. J Food Sci Technol 53:326–336

Felix M, Martinez I, Romero A, Partal P, Guerrero A (2018) Effect of pH and nanoclay content on the morphology and physicochemical properties of soy protein/montmorillonite nanocomposite obtained by extrusion. Compos B 140:197–203

Abdurrahim I (2019) Water sorption, antimicrobial activity, and thermal and mechanical properties of chitosan/clay/glycerol nanocomposite films. Heliyon 5:e02342

Kanmani P, Rhim J-W (2014) Physical, mechanical and antimicrobial properties of gelatin based active nanocomposite films containing AgNPs and nanoclay. Food Hydrocol 35:644–652

Shankar S, Wang LF, Rhim JW (2018) Incorporation of zinc oxide nanoparticles improved the mechanical, water vapor barrier, UV-light barrier, and antibacterial properties of PLA-based nanocomposite films. Mater Sci Eng C 93:289–298

Martín-Alfonso JE, Martín-Alfonso MJ, Valencia C, Cuberes MT (2021) Rheological and tribological approaches as a tool for the development of sustainable lubricating greases based on nano-montmorillonite and castor oil. Friction 9:415–428

Andrade-Guel M, Cabello-Alvarado C, Romero-Huitzil R, Rodríguez-Fernández O, Ávila-Orta C, Cadenas-Pliego G, Medellín-Banda D, Gallardo-Vega C, Cepeda-Garza J (2021) Nanocomposite PLA/C20A nanoclay by ultrasound-assisted melt extrusion for adsorption of uremic toxins and methylene blue dye. Nanomaterials 11:2477

Weng Y-X, Jin Y-J, Meng Q-Y, Wang L, Zhang M, Wang Y-Z (2013) Biodegradation behavior of poly(butylene adipate-co-terephthalate) (PBAT), poly(lactic acid) (PLA), and their blend under soil conditions. Polym Test 32:918–926

Araújo A, Botelho G, Oliveira M, Machado A (2014) Influence of clay organic modifier on the thermal-stability of PLA based nanocomposites. Appl Clay Sci 88:144–150

Krishnamachari P, Zhang J, Yan J, Shahbazi A, Uitenham L, Lou J (2007) Thermal characterization of biodegradable poly(lactic acid)/clay nanocomposites. National Conf Environ Sci Technol, Springer

Kumar M, Mohanty S, Nayak S, Parvaiz MR (2010) Effect of glycidyl methacrylate (GMA) on the thermal, mechanical and morphological property of biodegradable PLA/PBAT blend and its nanocomposites. Bioresour Technol 101:8406–8415

Naderi-Samani H, Razavi RS, Loghman-Estarki M, Ramazani M, Barekat M, Mishra A, Fattahi H (2019) The effects of Cloisite 20A content on the adhesion strength and corrosion behavior of poly(amide-imide)/Cloisite 20A nanocomposite coatings. Compos B 175:107154

Septevani AA, Bhakri S (2017) Plasticization of poly(lactic acid) using different molecular weight of poly(ethylene glycol). 3rd Int Symp Appl Chem, Am Instit Phys (AIP)

Kim I, Viswanathan K, Kasi G, Sadeghi K, Thanakkasaranee S, Seo J (2019) Poly(lactic acid)/ZnO bionanocomposite films with positively charged ZnO as potential antimicrobial food packaging materials. Polymers 11:1427

Pasha HY, Mohtasebi SS, Tajeddin B, Taherimehr M, Tabatabaeekoloor R, Firouz MS, Javadi A (2023) The effect of a new bionanocomposite packaging film on postharvest quality of strawberry at modified atmosphere condition. Food Bioproc Technol. https://doi.org/10.1007/s11947-022-02968-0

Acknowledgements

The authors would like to thank Iran National Science Foundation, INSF (Grant number: 99011944) and University of Tehran Science and Technology Park (Grant number: 120041) for providing financial support.

Funding

Iran National Science Foundation, 99011944, Masoumeh Taherimehr, Tehran Science and Technology Park, 120041, Seyed Saeid Mohtasebi.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pasha, H.Y., Mohtasebi, S.S., Taherimehr, M. et al. New poly(lactic acid)-based nanocomposite films for food packaging applications. Iran Polym J 32, 855–871 (2023). https://doi.org/10.1007/s13726-023-01170-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-023-01170-z