Abstract

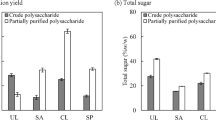

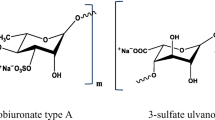

With increasing demand for biobased materials, major importance was given to the extraction and application of polysaccharides issued from renewable biomasses like algae. In this work, we investigate the feasibility of elaborating an active ulvan-based biomembrane prepared from stranded Ulva sp. biomass. Variations of extraction parameters showed that the optimal yield (13.8% w/w) was obtained using methanol under Soxhlet extraction for the defatting step and 5% (w/v) of ammonium oxalate as chelating reagent. The molecular weight (MW) was determined by gel permeation chromatography (GPC), which showed variability of MW from 201 to 1841 kDa depending on the extraction procedure. The monosaccharide composition of the obtained high MW ulvan showed the presence of rhamnose (17.61 ± 0.5%), xylose (9.22 ± 0.56%), and glucuronic acid (24.86 ± 1.29%). Purity and quality of ulvan were also assessed by FTIR and TGA analyses. The high MW ulvan fraction was thereafter used for the synthesis of a polyelectrolyte-type ulvan/chitosan biomembrane at low KCl concentration. The obtained membrane was then characterized using FTIR and XPS analyses, which evidenced that the ulvan sulfur groups were implicated in the interaction with chitosan chains. Finally, to assess the biological properties of the biomembrane, anticoagulant behavior was evaluated using APTT assay, and it has been found to significantly increase the blood clotting time in comparison with controls. This work shows the proof of concept of ulvan conversion to high added value products and, therefore, consolidates the implementation of cost-effective biorefinery approaches of green macroalgal biomass.

Similar content being viewed by others

Abbreviations

- FTIR:

-

Fourier transformed infrared spectroscopy

- XPS:

-

X-Ray photoelectron spectroscopy

- TGA:

-

Thermogravimetric analysis

- GPC:

-

Gel permeation chromatography

- SEM:

-

Scanning electron microscopy

- GC:

-

Gas chromatography

- APTT:

-

Activated partial thromboplastin time

References

Lahaye M, Ray B, Baumberger S, Quemener B, Axelos MAV (1996) Chemical characterisation and gelling properties of cell wall polysaccharides from species of Ulva (Ulvales, Chlorophyta). Hydrobiologia 327:473–480

Jmel MA, Anders N, Ben Yahmed N, Marzouki MN, Spiess A, Smaali I (2019) Efficient enzymatic saccharification of macroalgal biomass using a specific thermostable GH 12 endoglucanase from Aspergillus terreus JL1. World J Microbiol Biotechnol 36(1):5. https://doi.org/10.1007/s11274-019-2779-6

Van den Burg S, Stuiver M, Veenstra F, Bikker P, Contreras AL, Palstra A, Broeze J, Jansen H, Jak R, Gerritsen A (2013) A triple P review of the feasibility of sustainable offshore seaweed production in the North Sea. Wageningen UR,

Goh CS, Lee KT (2010) A visionary and conceptual macroalgae-based third-generation bioethanol (TGB) biorefinery in Sabah, Malaysia as an underlay for renewable and sustainable development. Renew Sust Energ Rev 14(2):842–848

Smaali I, Maugard T, Limam F, Legoy M-D, Marzouki N (2007) Efficient synthesis of gluco-oligosaccharides and alkyl-glucosides by transglycosylation activity of β-glucosidase from Sclerotinia sclerotiorum. World J Microbiol Biotechnol 23:145–149

Robic A, Bertrand D, Sassi J-F, Lerat Y, Lahaye M (2009) Determination of the chemical composition of ulvan, a cell wall polysaccharide from Ulva spp. (Ulvales, Chlorophyta) by FT-IR and chemometrics. J Appl Phycol 21(4):451–456

Ben Yahmed N, Berrejeb N, Jmel MA, Jazzar S, Marzouki MN, Smaali I (2018) Efficient biocatalytic conversion of stranded green macroalgal biomass using a specific cellulases-based cocktail. Waste Biomass Valor 11:211–222. https://doi.org/10.1007/s12649-018-0397-4

Ben Yahmed N, Carrere H, Marzouki MN, Smaali I (2017) Enhancement of biogas production from Ulva sp by using solid-state fermentation as biological pretreatment. Algal Res 27:206–214. https://doi.org/10.1016/j.algal.2017.09.005

Kidgell JT, Magnusson M, de Nys R, Glasson CRK (2019) Ulvan: a systematic review of extraction, composition and function. Algal Res 39:101422. https://doi.org/10.1016/J.Algal.2019.101422

Robic A, Gaillard C, Sassi JF, Lerat Y, Lahaye M (2009) Ultrastructure of ulvan: a polysaccharide from green seaweeds. Biopolymers 91(8):652–664

Jmel MA, Messaoud GB, Marzouki MN, Mathlouthi M, Smaali I (2016) Physico-chemical characterization and enzymatic functionalization of Enteromorpha sp. cellulose. Carbohydr Polym 135:274–279

Wijesekara I, Pangestuti R, Kim SK (2011) Biological activities and potential health benefits of sulfated polysaccharides derived from marine algae. Carbohydr Polym 84(1):14–21. https://doi.org/10.1016/j.carbpol.2010.10.062

Tabarsa M, You S, Dabaghian EH, Surayot U (2018) Water-soluble polysaccharides from Ulva intestinalis: molecular properties, structural elucidation and immunomodulatory activities. J Food Drug Anal 26(2):599–608. https://doi.org/10.1016/j.jfda.2017.07.016

Adrien A, Dufour D, Baudouin S, Maugard T, Bridiau N (2017) Evaluation of the anticoagulant potential of polysaccharide-rich fractions extracted from macroalgae. Nat Prod Res 31(18):2126–2136. https://doi.org/10.1080/14786419.2017.1278595

Kaeffer B, Benard C, Lahaye M, Blottiere HM, Cherbut C (1999) Biological properties of ulvan, a new source of green seaweed sulfated polysaccharides, on cultured normal and cancerous colonic epithelial tells. Planta Med 65(6):527–531. https://doi.org/10.1055/S-1999-14009

Yu PZ, Li N, Liu XG, Zhou GF, Zhang QB, Li PC (2003) Antihyperlipidemic effects of different molecular weight sulfated polysaccharides from Ulva pertusa (Chlorophyta). Pharmacol Res 48(6):543–549. https://doi.org/10.1016/S1043-6618(03)00215-9

Shi QM, Wang AJ, Lu ZH, Qin CJ, Hu J, Yin J (2017) Overview on the antiviral activities and mechanisms of marine polysaccharides from seaweeds. Carbohydr Res 453-454:1–9. https://doi.org/10.1016/j.carres.2017.10.020

Paulert R, Ebbinghaus D, Urlass C, Moerschbacher BM (2010) Priming of the oxidative burst in rice and wheat cell cultures by ulvan, a polysaccharide from green macroalgae, and enhanced resistance against powdery mildew in wheat and barley plants. Plant Pathol 59(4):634–642. https://doi.org/10.1111/j.1365-3059.2010.02300.x

Pasqui D, De Cagna M, Barbucci R (2012) Polysaccharide-Based hydrogels: the key role of water in affecting mechanical properties. Polymers-Basel 4(3):1517–1534. https://doi.org/10.3390/polym4031517

Guidara M, Yaich H, Benelhadj S, Adjouman YD, Richel A, Blecker C, Sindic M, Boufi S, Attia H, Garna H (2020) Smart ulvan films responsive to stimuli of plasticizer and extraction condition in physico-chemical, optical, barrier and mechanical properties. Int J Biol Macromol 150:714–726. https://doi.org/10.1016/j.ijbiomac.2020.02.111

Lakshmi DS, Sankaranarayanan S, Gajaria TK, Li GQ, Kujawski W, Kujawa J, Navia R (2020) A short review on the valorization of green seaweeds and ulvan: feedstock for chemicals and biomaterials. Biomolecules 10(7):991. https://doi.org/10.3390/Biom10070991

Dash M, Samal SK, Morelli A, Bartoli C, Declercq HA, Douglas TEL, Dubruel P, Chiellini F (2018) Ulvan-chitosan polyelectrolyte complexes as matrices for enzyme induced biomimetic mineralization. Carbohydr Polym 182:254–264. https://doi.org/10.1016/j.carbpol.2017.11.016

Toskas G, Heinemann S, Heinemann C, Cherif C, Hund R-D, Roussis V, Hanke T (2012) Ulvan and ulvan/chitosan polyelectrolyte nanofibrous membranes as a potential substrate material for the cultivation of osteoblasts. Carbohydr Polym 89:997–1002. https://doi.org/10.1016/j.carbpol.2012.04.045

Jmel MA, Anders N, Ben Messaoud G, Marzouki MN, Spiess A, Smaali I (2019) The stranded macroalga Ulva lactuca as a new alternative source of cellulose: extraction, physicochemical and rheological characterization. J Clean Prod 234:1421–1427. https://doi.org/10.1016/j.jclepro.2019.06.225

Pohan G, Chevallier P, Anderson DEJ, Tse JW, Yao Y, Hagen MW, Mantovani D, Hinds MT, Yim EKF (2019) Luminal plasma treatment for small diameter polyvinyl alcohol tubular scaffolds. Front Bioeng Biotechnol 7:117. https://doi.org/10.3389/Fbioe.2019.00117

Vasconcelos NF, Andrade FK, Vieira LAP, Vieira RS, Vaz JM, Chevallier P, Mantovani D, de Fátima Borges M, de Freitas Rosa M (2020) Oxidized bacterial cellulose membrane as support for enzyme immobilization: properties and morphological features. Cellulose 27:3055–3083.https://doi.org/10.1007/s10570-020-02966-5

Messaoud M, Houmard M, Briche S, Roussel F, Langlet M (2010) Hydrophobic functionalization of cotton-based textile fabrics through a non-fluorinated solgel route. J Sol-Gel Sci Technol 55:243–254

Diaz-Rodriguez S, Chevallier P, Paternoster C, Montano-Machado V, Noel C, Houssiau L, Mantovani D (2019) Surface modification and direct plasma amination of L605 CoCr alloys: on the optimization of the oxide layer for application in cardiovascular implants. RSC Adv 9(4):2292–2301. https://doi.org/10.1039/c8ra08541b

Blakeney AB, Harris PJ, Henry RJ, Stone BA (1983) A simple and rapid preparation of alditol acetates for monosaccharide analysis. Carbohydr Res 113(2):291–299. https://doi.org/10.1016/0008-6215(83)88244-5

Lima PHL, Pereira SVA, Rabello RB, Rodriguez-Castellon E, Beppu MM, Chevallier P, Mantovani D, Vieira RS (2013) Blood protein adsorption on sulfonated chitosan and kappa-carrageenan films. Colloids Surf B: Biointerfaces 111:719–725. https://doi.org/10.1016/j.colsurfb.2013.06.002

Tziveleka LA, Ioannou E, Roussis V (2019) Ulvan, a bioactive marine sulphated polysaccharide as a key constituent of hybrid biomaterials: a review. Carbohydr Polym 218:355–370. https://doi.org/10.1016/j.carbpol.2019.04.074

Tziveleka LA, Pippa N, Georgantea P, Ioannou E, Demetzos C, Roussis V (2018) Marine sulfated polysaccharides as versatile polyelectrolytes for the development of drug delivery nanoplatforms: complexation of ulvan with lysozyme. Int J Biol Macromol 118(Pt A):69–75. https://doi.org/10.1016/j.ijbiomac.2018.06.050

Chi Y, Li H, Wang P, Du C, Ye H, Zuo S, Guan H, Wang P (2020) Structural characterization of ulvan extracted from Ulva clathrata assisted by an ulvan lyase. Carbohydr Polym 229:115497. https://doi.org/10.1016/j.carbpol.2019.115497

Qi HM, Huang LY, Liu XL, Liu DM, Zhang QB, Liu SM (2012) Antihyperlipidemic activity of high sulfate content derivative of polysaccharide extracted from Ulva pertusa (Chlorophyta). Carbohydr Polym 87(2):1637–1640. https://doi.org/10.1016/j.carbpol.2011.09.073

Yaich H, Ben Amira A, Abbes F, Bouaziz M, Besbes S, Richel A, Blecker C, Attia H, Garna H (2017) Effect of extraction procedures on structural, thermal and antioxidant properties of ulvan from Ulva lactuca collected in Monastir coast. Int J Biol Macromol 105(Pt 2):1430–1439. https://doi.org/10.1016/j.ijbiomac.2017.07.141

Robic A, Sassi JF, Dion P, Lerat Y, Lahaye M (2009) Seasonal Variability of physicochemical and rheological properties of ulvan in two Ulva species (Chlorophyta) from the Brittany Coast(1). J Phycol 45(4):962–973. https://doi.org/10.1111/j.1529-8817.2009.00699.x

Kaeffer B, Benard C, Lahaye M, Blottiere HM, Cherbut C (1999) Biological properties of ulvan, a new source of green seaweed sulfated polysaccharides, on cultured normal and cancerous colonic epithelial cells. Planta Med 65(6):527–531. https://doi.org/10.1055/s-1999-14009

Lahaye M, Robic A (2007) Structure and functional properties of ulvan, a polysaccharide from green seaweeds. Biomacromolecules 8(6):1765–1774. https://doi.org/10.1021/bm061185q

Jmel MA, Anders N, Yahmed NB, Schmitz C, Marzouki MN, Spiess A, Smaali I (2018) Variations in physicochemical properties and bioconversion efficiency of Ulva lactuca polysaccharides after different biomass pretreatment techniques. Appl Biochem Biotechnol 184(3):777–793. https://doi.org/10.1007/s12010-017-2588-z

Robic A, Sassi JF, Dion P, Lerat Y, Lahaye M (2009) Seasonal variability of physicochemical and rheological properties of ulvan in two Ulva species (Chlorophyta) from the Brittany Coast. J Phycol 45(4):962–973. https://doi.org/10.1111/j.1529-8817.2009.00699.x

Li P, Wen S, Sun K, Zhao Y, Chen Y (2018) Structure and bioactivity screening of a low molecular weight ulvan from the green alga ulothrix flacca. Mar Drugs 16(8). https://doi.org/10.3390/md16080281

Ramu Ganesan A, Shanmugam M, Bhat R (2018) Producing novel edible films from semi refined carrageenan (SRC) and ulvan polysaccharides for potential food applications. Int J Biol Macromol 112:1164–1170. https://doi.org/10.1016/j.ijbiomac.2018.02.089

Gadenne V, Lebrun L, Jouenne T, Thebault P (2013) Antiadhesive activity of ulvan polysaccharides covalently immobilized onto titanium surface. Colloids Surf B: Biointerfaces 112:229–236. https://doi.org/10.1016/j.colsurfb.2013.07.061

Wang X, Zhang Z, Yao Z, Zhao M, Qi H (2013) Sulfation, anticoagulant and antioxidant activities of polysaccharide from green algae Enteromorpha linza. Int J Biol Macromol 58:225–230. https://doi.org/10.1016/j.ijbiomac.2013.04.005

Reis SE, Andrade RGC, Accardo CM, Maia LF, Oliveira LFC, Nader HB, Aguiar JAK, Medeiros VP (2020) Influence of sulfated polysaccharides from Ulva lactuca L. upon Xa and IIa coagulation factors and on venous blood clot formation. Algal Res 45:101750. https://doi.org/10.1016/J.Algal.2019.101750

Acknowledgements

Dr. Rodrigo S. Vieira from the Federal University of Ceará - Brazil is acknowledged for his support and assistance in GPC analyses.

Funding

The authors received from the Tunisian Ministry of Higher Education and Scientific Research financial support (project LR11ES24) and the University of Carthage (Tunisia) the concession of a research grant which has permitted Cyrine Ben Amor to carry out this research at the University Laval, Quebec.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ben Amor, C., Jmel, M.A., Chevallier, P. et al. Efficient extraction of a high molecular weight ulvan from stranded Ulva sp. biomass: application on the active biomembrane synthesis. Biomass Conv. Bioref. 13, 3975–3985 (2023). https://doi.org/10.1007/s13399-021-01426-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01426-9