Abstract

Microspheres have gained much attention from pharmaceutical and medical industry due to the excellent biodegradable and long controlled-release characteristics. However, the drug release behavior of microspheres is influenced by complicated formulation and manufacturing factors. The traditional formulation development of microspheres is intractable and inefficient by the experimentally trial-and-error methods. This research aims to build a prediction model to accelerate microspheres product development for small-molecule drugs by machine learning (ML) techniques. Two hundred eighty-six microsphere formulations with small-molecule drugs were collected from the publications and pharmaceutical company, including the dissolution temperature at both 37 ℃ and 45 ℃. After the comparison of fourteen ML approaches, the consensus model achieved accurate predictions for the validation set at 37 ℃ and 45 ℃ (R2 = 0.880 vs. R2 = 0.958), indicating the good performance to predict the in vitro drug release profiles at both 37 ℃ and 45 ℃. Meanwhile, the models revealed the feature importance of formulations, which offered meaningful insights to the microspheres development. Experiments of microsphere formulations further validated the accuracy of the consensus model. Furthermore, molecular dynamics (MD) simulation provided a microscopic view of the preparation process of microspheres. In conclusion, the prediction model of microsphere formulations for small-molecule drugs was successfully built with high accuracy, which is able to accelerate microspheres product development and promote the quality control of microspheres for the pharmaceutical industry.

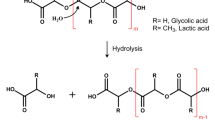

Graphical Abstract

Similar content being viewed by others

Availability of data and materials

All data and code will be available from the corresponding author on reasonable request.

References

O’Brien MN, Jiang W, Wang Y, Loffredo DM. Challenges and opportunities in the development of complex generic long-acting injectable drug products. J Control Release. 2021;336:144–58.

Burgess DJ, Wright JC. An introduction to long acting injections and implants. In: Wright JC, Burgess DJ, editors. Long Acting Injections and Implants. US, Boston, MA: Springer; 2012. p. 1–9.

Wang Y, Burgess DJ. Microsphere Technologies. In: Wright JC, Burgess DJ, editors. Long acting injections and implants. US, Boston, MA: Springer; 2012. p. 167–94.

Wong CY, Al-Salami H, Dass CR. Microparticles, microcapsules and microspheres: a review of recent developments and prospects for oral delivery of insulin. Int J Pharm. 2018;537:223–44.

Su Y, Zhang B, Sun R, Liu W, Zhu Q, Zhang X, Wang R, Chen C. PLGA-based biodegradable microspheres in drug delivery: recent advances in research and application. Drug Deliv. 2021;28:1397–418.

Göpferich A. Mechanisms of polymer degradation and erosion. Biomaterials. 1996;17:103–14.

Yoo J, Won Y-Y. Phenomenology of the initial burst release of drugs from PLGA microparticles. ACS Biomater Sci Eng. 2020;6:6053–62.

Fredenberg S, Wahlgren M, Reslow M, Axelsson A. The mechanisms of drug release in poly(lactic-co-glycolic acid)-based drug delivery systems—a review. Int J Pharm. 2011;415:34–52.

Wang Y, Qu W, Choi SH. FDA’s regulatory science program for generic PLA/ PLGA-based drug products. Am Pharm Rev. 2016.

Burgess DJ, Crommelin DJA, Hussain AS, Chen M-L. Assuring quality and performance of sustained and controlled release parenterals. Eur J Pharm Sci. 2004;21:679–90.

Lundström EA, Rencken RK, van Wyk JH, Coetzee LJ, Bahlmann JC, Reif S, Strasheim EA, Bigalke MC, Pontin AR, Goedhals L, Steyn DG, Heyns CF, Aldera LA, Mackenzie TM, Purcea D, Grosgurin PY, Porchet HC. Triptorelin 6-month formulation in the management of patients with locally advanced and metastatic prostate cancer: an open-label, non-comparative, multicentre, phase III study. Clin Drug Investig. 2009;29:757–65.

Vamathevan J, Clark D, Czodrowski P, Dunham I, Ferran E, Lee G, Li B, Madabhushi A, Shah P, Spitzer M, Zhao S. Applications of machine learning in drug discovery and development. Nat Rev Drug Discovery. 2019;18:463–77.

Han R, Xiong H, Ye Z, Yang Y, Huang T, Jing Q, Lu J, Pan H, Ren F, Ouyang D. Predicting physical stability of solid dispersions by machine learning techniques. J Control Release. 2019;311–312:16–25.

Gao H, Wang W, Dong J, Ye Z, Ouyang D. An integrated computational methodology with data-driven machine learning, molecular modeling and PBPK modeling to accelerate solid dispersion formulation design. Eur J Pharm Biopharm. 2021;158:336–46.

He Y, Ye Z, Liu X, Wei Z, Qiu F, Li H-F, Zheng Y, Ouyang D. Can machine learning predict drug nanocrystals? J Control Release. 2020;322:274–85.

Wang W, Feng S, Ye Z, Gao H, Lin J, Ouyang D. Prediction of lipid nanoparticles for mRNA vaccines by the machine learning algorithm. Acta Pharm Sin B. 2021.

Gao H, Jia H, Dong J, Yang X, Li H, Ouyang D. Integrated in silico formulation design of self-emulsifying drug delivery systems. Acta Pharmaceutica Sinica B. 2021.

Ye Z, Yang W, Yang Y, Ouyang D. Interpretable machine learning methods for in vitro pharmaceutical formulation development, Food. Frontiers. 2021;2:195–207.

Versypt AN, Pack DW, Braatz RD. Mathematical modeling of drug delivery from autocatalytically degradable PLGA microspheres — a review. J Controlled Rel. 2013;165:29–37.

Zawbaa HM, Szlȩk J, Grosan C, Jachowicz R, Mendyk A. Computational intelligence modeling of the macromolecules release from PLGA microspheres-focus on feature selection. PLoS ONE. 2016;11: e0157610.

Rodrigues de Azevedo C, von Stosch M, Costa MS, Ramos AM, Cardoso MM, Danhier F, Préat V, Oliveira R. Modeling of the burst release from PLGA micro- and nanoparticles as function of physicochemical parameters and formulation characteristics. Int J Pharm. 2017;532:229–40.

Bannigan P, Häse F, Aldeghi M, Bao Z, Aspuru-Guzik A, Allen C. Machine learning predictions of drug release from polymeric long acting injectables. ChemRxiv. Cambridge: Cambridge Open Engage. 2021.

Tetko IV, Gasteiger J, Todeschini R, Mauri A, Livingstone D, Ertl P, Palyulin VA, Radchenko EV, Zefirov NS, Makarenko AS, Tanchuk VY, Prokopenko VV. Virtual computational chemistry laboratory – design and description. J Comput Aided Mol Des. 2005;19:453–63.

Han R, Yang Y, Li X, Ouyang D. Predicting oral disintegrating tablet formulations by neural network techniques, Asian. J Pharm Sci. 2018;13:336–42.

Yang Y, Ye Z, Su Y, Zhao Q, Li X, Ouyang D. Deep learning for in vitro prediction of pharmaceutical formulations. Acta Pharm Sin B. 2018.

Shah VP, Tsong Y, Sathe P, Liu J-P. In vitro dissolution profile comparison—statistics and analysis of the similarity factor, f2. Pharm Res. 1998;15:889–96.

FDA, Guidance for Industry. SUPAC‐IR. Immediate release solid oral dosage forms. Scale‐up and post approval changes. Chemistry, manufacturing and controls. In vitro dissolution testing and in vivo bioequivalence documentation. 1995.

Bastien F, Lamblin P, Pascanu R, Bergstra J, Goodfellow I, Bergeron A, Bouchard N, Warde-Farley D, Bengio Y. Theano: new features and speed improvements. 2012. arXiv:1211.5590.

Abadi M, Barham P, Chen J, Chen Z, Davis A, Dean J, Devin M, Ghemawat S, Irving G, Isard M, Kudlur M, Levenberg J, Monga R, Moore S, Murray DG, Steiner B, Tucker P, Vasudevan V, Warden P, Wicke M, Yu Y, Zheng X. TensorFlow: a system for large-scale machine learning. In: Proc 12th USENIX Conf Operating Sys Des Implement, USENIX Association, Savannah, GA, USA. 2016;265–283.

Lei T, Li Y, Song Y, Li D, Sun H, Hou T. ADMET evaluation in drug discovery: 15. Accurate prediction of rat oral acute toxicity using relevance vector machine and consensus modeling, Journal of cheminformatics. 2016;8:6.

Wang Y, Huang W, Wang N, Ouyang D, Xiao L, Zhang S, Ou X, He T, Yu R, Song L. Development of arteannuin B sustained-release microspheres for anti-tumor therapy by integrated experimental and molecular modeling approaches Pharmaceutics. 2021;13.

Wang J, Wolf RM, Caldwell JW, Kollman PA, Case DA. Development and testing of a general amber force field 2004;25:1157–1174.

Jakalian A, Bush BL, Jack DB, Bayly CI. Fast, efficient generation of high-quality atomic charges. AM1-BCC Model: I Method, J Comput Chem. 2000;21:132–146.

Martínez L, Andrade R, Birgin EG, Martínez JM. PACKMOL: a package for building initial configurations for molecular dynamics simulations. J Comput Chem. 2009;30:2157–64.

Humphrey W, Dalke A, Schulten K. VMD: visual molecular dynamics. 1996;14:33–38.

Liu J, Li D, Liu X. A simple and accurate algorithm for path integral molecular dynamics with the Langevin thermostat. J Chem Phys. 2016;145.

Berendsen HJ, Postma JV, Van Gunsteren WF, DiNola AR, Haak JR. Molecular dynamics with coupling to an external bath. 1984;81:3684–3690.

Park K, Skidmore S, Hadar J, Garner J, Park H, Otte A, Soh BK, Yoon G, Yu D, Yun Y, Lee BK, Jiang X, Wang Y. Injectable, long-acting PLGA formulations: analyzing PLGA and understanding microparticle formation. J Control Release. 2019;304:125–34.

Skiveren J, Nordahl Larsen H, Kjaerby E, Larsen R. The influence of needle size on pain perception in patients treated with botulinum toxin A injections for axillary hyperhidrosis. Acta dermato-venereologica. 2011;91:72–74.

Gill HS, Prausnitz MR. Does needle size matter? J Diabetes Sci Technol. 2007;1:725–9.

Haas P, Falkner-Radler C, Wimpissinger B, Malina M, Binder S. Needle size in intravitreal injections - pain evaluation of a randomized clinical trial. Acta Ophthalmol. 2016;94:198–202.

Wischke C, Schwendeman SP. Principles of encapsulating hydrophobic drugs in PLA/PLGA microparticles. Int J Pharm. 2008;364:298–327.

Wang J, Wang BM, Schwendeman SP. Characterization of the initial burst release of a model peptide from poly(d, l-lactide-co-glycolide) microspheres. J Control Release. 2002;82:289–307.

Flory PJ. Thermodynamics of high polymer solutions. J Chem Phys. 1941;9:660–1.

Flory PJ, Krigbaum WR. Statistical mechanics of dilute polymer solutions II. 1950;18:1086–1094.

Zolnik BS, Leary PE, Burgess DJ. Elevated temperature accelerated release testing of PLGA microspheres. J Control Release. 2006;112:293–300.

Yeo Y, Park K. Control of encapsulation efficiency and initial burst in polymeric microparticle systems. Arch Pharmacal Res. 2004;27:1.

Rosca ID, Watari F, Uo M. Microparticle formation and its mechanism in single and double emulsion solvent evaporation. J Control Release. 2004;99:271–80.

Shrivastava A. 1 - Introduction to plastics engineering. In: Shrivastava A, editor. Introduction to Plastics Engineering. William Andrew Publishing; 2018. p. 1–16.

Prudic A, Lesniak AK, Ji Y, Sadowski G. Thermodynamic phase behaviour of indomethacin/PLGA formulations. Eur J Pharm Biopharm: Official J Arbeitsgemeinschaft Fur Pharmazeutische Verfahrenstechnik e.V. 2015;93:88–94.

Rawat A, Bhardwaj U, Burgess DJ. Comparison of in vitro–in vivo release of Risperdal® Consta® microspheres. Int J Pharm. 2012;434:115–21.

Andhariya JV, Burgess DJ. Recent advances in testing of microsphere drug delivery systems. Expert Opin Drug Deliv. 2016;13:593–608.

Shen J, Lee K, Choi S, Qu W, Wang Y, Burgess DJ. A reproducible accelerated in vitro release testing method for PLGA microspheres. Int J Pharm. 2016;498:274–82.

Park K, Otte A, Sharifi F, Garner J, Skidmore S, Park H, Jhon YK, Qin B, Wang Y. Potential roles of the glass transition temperature of PLGA microparticles in drug release kinetics. Mol Pharm. 2021;18:18–32.

Struik LCE. Physical aging in amorphous polymers and other materials. 1977.

Yoshioka T, Kawazoe N, Tateishi T, Chen GJMM. Engineering. Effects of structural change induced by physical aging on the biodegradation behavior of PLGA films at physiological temperature. 2011;296:1028–34.

Acknowledgements

Molecular modeling was performed at the High-Performance Computing Cluster (HPCC) which is supported by Information and Communication Technology Office (ICTO) of the University of Macau.

Funding

Current research is financially supported by the Zhuhai-HongKong-Macau Collaboration Project (ZH22017002210010PWC) and the Macau FDCT research grant (0108/2021/A).

Author information

Authors and Affiliations

Contributions

Jiayin Deng: data collection, molecular dynamic simulation, and writing—original draft preparation; Zhuyifan Ye: machine learning modeling and writing—reviewing and editing; Wenwen Zheng: study design and revision; Jian Chen: experimental work; Haoshi Gao: data analysis; Zheng Wu: platform construction; Ging Chan: supervision; Yongjun Wang: supervision; Dongsheng Cao: supervision; Yanqing Wang: study conception and design; Simon Ming-Yuen Lee: study conception and design; Defang Ouyang: study conception and design and writing—reviewing and editing.

Corresponding authors

Ethics declarations

Ethics approval and consent to participate

No ethical approval is required for this study.

Consent for publication

All authors have agreed with publication of the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

ESM 1

(DOCX 1.24 MB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, J., Ye, Z., Zheng, W. et al. Machine learning in accelerating microsphere formulation development. Drug Deliv. and Transl. Res. 13, 966–982 (2023). https://doi.org/10.1007/s13346-022-01253-z

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13346-022-01253-z