Abstract

Ohmic heating or Joule heating has immense potential for achieving rapid and uniform heating in foods, providing microbiologically safe and high quality foods. This review discusses the technology behind ohmic heating, the current applications and thermal modeling of the process. The success of ohmic heating depends on the rate of heat generation in the system, the electrical conductivity of the food, electrical field strength, residence time and the method by which the food flows through the system. Ohmic heating is appropriate for processing of particulate and protein rich foods. A vast amount of work is still necessary to understand food properties in order to refine system design and maximize performance of this technology in the field of packaged foods and space food product development. Various economic studies will also play an important role in understanding the overall cost and viability of commercial application of this technology in food processing. Some of the demerits of the technology are also discussed.

Similar content being viewed by others

References

Allen K, Eidman V, Kinsey J (1996) An economic-engineering study of ohmic food processing. Food Tech 50:269–273

Amatore C, Berthou M, Hebert S (1998) Fundamental principles of electrochemical ohmic heating of solutions. J Electroanal Chem 457:191–203

Anderson A, Finkelstein R (1919) Study of the electro pure process of treating milk. J Dairy Sci 2:374–406

Ayadi MA, Bouvier L, Chopard F, Berthou M, Fillaudea L, Leuliet JC (2003) In: Heat treatment improvement of dairy products via ohmic heating processes: thermal and hydrodynamic effect on fouling. Proceedings of heat exchanger fouling and cleaning—fundamentals and applications. Santa Fe, N.M., U.S.A.; May 18–22. 2003 Engineering Conferences International, New York, U.S.A

Ayadi MA, Leuliet JC, Chopard F, Berthou M, Lebouche M (2004) Continuous ohmic heating unit under whey protein fouling. Innovat Food Sci Emerg Tech 5:465–473

Ayadi MA, Benezech T, Chopard F, Berthou M, Leuliet JC (2005a) Heat treatment of dairy product by a flat ohmic cell: impact of the Reynolds number, fluid rheology and deposit presence on the electrode surface temperature. Heat Exchanger Fouling and Cleaning: Challenges and Opportunities, Engineering Conferences Intl.; Kloster Irsee, Germany; June 5–10: Engineering Conferences International, New York, U. S. A 2005

Ayadi MA, Leuliet JC, Chopard F, Berthou M, Lebouché M (2005b) Experimental study of hydrodynamics in a flat ohmic cell—impact on fouling by dairy products. J Food Eng 70:489–498

Bansal B, Chen XD (2005) Modelling of milk fouling during ohmic heating. CHEMECA Conference; Brisbane, Australia; 2005 Sept 25–8. Institute of Engineers, Australia

Bansal B, Chen XD, Lin SXQ (2005) Skim milk fouling during ohmic heating. Heatexchanger fouling and cleaning: challenges and opportunities. Engineering Conferences Intl.; Kloster Irsee, Germany; 2005 June 5–10: Engineering Conferences International, New York, U.S.A

Beatty RL, Sutto WH, Iskander MF (1992) Microwave processing of materials. Materials Research Society Symposium Proceedings, San Francisco, Ca

Benabderrahmane Y, Pain JP (2000) Thermal behaviour of a solid/liquid mixture in an ohmic heating sterilizer–slip phase model. Chem Eng Sci 55:1371–1384

Bertolini MA, Romagnoli G (1996) Target cost evaluation for the ohmic treatment of a vegetable soup: an Italian comparative case study international conference on food innovation, Food Innova 2010, 25–29 0ctober 2010 Universidad politecnica de Valencia

Bozkurt H, Icier F (2009) Electrical conductivity changes of minced beef–fat blends during ohmic cooking. J Food Eng 96:86–92

Brunton NP, Lyng JG, Li W, Cronin DA, Morgan D, McKenna B (2005) Effect of radio frequency (RF) heating on the texture, colour and sensory properties of a comminuted pork meat product. Food Res Int 38(3):337–344

Castro I, Teixeira JA, Salengke S, Sastry SK, Vicente AA (2004) Ohmic heating of strawberry products: electrical conductivity measurements and ascorbic acid degradation kinetics. Innovat Food Sci Emerg Tech 5:27–36

Chandarana DI, Unverferth JA (1996) Residence time distribution of particulate foods at aseptic processing temperatures. J Food Eng 28:349–360

Cheremisinoff PN, Farah OG, Ouellette RP (1985) Radio frequency/radiation and plasma processing: industrial applications & advances. Technomic Publishing Co, Lancaster

Datta AK, Hu W (1992) Optimization of quality in microwave heating. Food Tech 46(12):53–56

de Alwis AAP, Fryer PJ (1990) The use of direct resistance heating in the food industry. J Food Eng 11:3–27

de Halleux G, Piett M, Buteau ML, Dostie A (2005) Ohmic cooking of processed meats: energy evaluation and food safety considerations. Can Biosyst Eng 47:3.41–3.47

De Jong P (1996) Modeling and optimization of thermal processes in the dairy industry. NIZO Verslag, Ede, p 341

Decareau RV (1985) Microwave in the food processing industry. Academic, Orlando

Di Geronimo M, Garthright LJ (1997) Statistical design and analysis. Food Tech 51(10):52–54

Drusas A, Vagenas GK (1988) Diffusion of sodium chloride in green olives. J Food Eng 7:211–222

Dussap G, Gros JB (1980) Diffusion sorption model for salt in pork and beef muscle. In: Linko P, Malkki Y, Olkku J, Laringkari J (eds) Food Proc Engg Applied Science Publishers, London, pp 407–411

Elzubier AS, Thomas CSY, Sergie SY, Chin NL, Ibrahim OM (2009) The effect of buoyancy force in computational fluid dynamics simulation of a two-dimensional continuous ohmic heating process. Am J Appl Sci 6(11):1902–1908

Fryer PJ, deAlwis AAP, Koury E, Stapley AGF, Zhang L (1993) Ohmic processing of solid–liquid mixtures: heat generation and convection effects. J Food Eng 18:101–125

Goullieux A, Pain J (2005) Ohmic heating. Emerging technologies for food. Elsevier Academic Press, London, pp 469–505

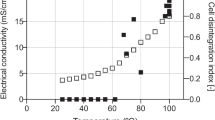

Halden K, de Alwis AAP, Fryer PJ (1990) Changes in electrical conductivity of foods during ohmic heating. Int J Food Sci Tech 25:9–25

Houben J, Schoenmakers L, Van Pu’iten E, Van Roon P, Krol B (1991) Radio-frequency pasteurization of sausage emulsions as a continuous process. J Microw Power Electromagn Energ 26(4):1.171–1.177

Içi’er F, Yildiz H, Baysal T (2008) Polyphenoloxidase deactivation kinetics during ohmic heating of grape juice. J Food Eng 85(3):410–417

Icier F, Ilicali C (2005) Temperature dependent electrical conductivities of fruit purees during ohmic heating. Food Res Int 38:1135–1142

Imai T, Uemura K, Ishida N, Yoshizaki S, Noguchi A (1995) Ohmic heating of Japanese white radish Raphanus sativus L. Int J Food Sci Technol 30:461–472

Ishii TK (1995) Handbook of microwave technology: vol. 2. Applications. Academic, San Diego

Jun S, Sastry S (2005) Modeling and optimization of ohmic heating of foods inside a flexible package. J Food Process Eng 28:417–436

Jun S, Sastry S, Samaranayake C (2007) Migration of electrode components during ohmic heating of foods in retort pouches. Innovat Food Sci Emerg Tech 8:237–243

Kanjanapongkul K, Yoovidhya T, Tia S, Wongsa-Ngasri P (2008) Protein removal from fish mince washwater using ohmic heating. Songklanakarin J Sci Technol 30(3):413–419

Katrokha I, Matvienko A, Vorona I, Kupchik M, Zaets V (1984) Intensification of sugar extraction from sweet sugar beet cossettes in an electric field. Sakharnaya Promyshlennost 7:28–31

Khalaf WG, Sastry SK (1996) Effect of fluid viscosity on the ohmic heating rate of solid–liquid mixtures. J Food Eng 27:125–158

Kim J, Pyun Y (1995) Extraction of soy milk using ohmic heating. Abstract, 9th Congress of Food Sci. Technol., Budapest, Hungary 1995

Knirsch MC, Santos CA, Martins AA, Vincente OA, Penne TCV (2010) Ohmic heating—a review. Trends Food Sci Tech 21:436–441

Kolbe E, Park JW, Well JH, Flugstad BA, Zhao Y (2001) Capacitive dielectric heating system. U.S. Patent, 6,303,166. Issued October 16, 2001

Kuang W, Nelson SO (1998) Low-frequency dielectric properties of biological tissue: a review with some new insights. Trans ASAE 41(1):173–178

Lakkakula N, Lima M, Walker T (2004) Rice bran stabilization and rice bran oil extraction using ohmic heating. J Biores Technol 92:157–161

Lima M, Sastry SK (1999a) The effects of ohmic heating frequency on hot-air drying rate and juice yield. J Food Sci 41:115–119

Lima M, Sastry SK (1999b) The effects of ohmic heating frequency on hot-air drying and juice yield. J Food Eng 41:115–119

Lima M, Heskett BF, Sastry SK (1999) The effect of frequency and waveform on the electrical conductivity-temperature profiles of turnip tissue. J Food Process Eng 22:41–54

Lima M, Hesket BF, Sastry SK (2001) The effect of frequency andwaveform on the electrical conductivity-temperature profiles of turnip tissue. J Food Process Eng 22:41–54

Liu HA (1992) Kinetic study of salt diffusion in potato at high temperature. Int J Food Sci Technol 27:443–455

Liu Z, Jayasinghe S, Gao W, Farid M (2007) Corrosion mechanism of electrodes in ohmic cooking. Asia-Pac J Chem Eng 2:487–492

Loypimai P, Moonggarm A, Chottano P (2009) Effects of ohmic heating on lipase activity, bioactive compounds and antioxidant activity of rice bran. Aust J Basic Appl Sci 3(4):3642–3652

Luzuriaga DA, Roberts JS, Balaban MO (1996) Electrical conductivity of frozen shrimp and flounder at different temperatures and voltage levels. J Agric Food Proc Technol 3(5):41–63

Marcotte M, Trigui M, Ramaswamy HS (2000) Effect of salt and citric acid on electrical conductivities and ohmic heating of viscous liquids. J Food Process Preserve 24:389–406

Marra F, Zell M, Lyng JG, Morgan DJ, Cronin DA (2009) Analysis of heat transfer during ohmic processing of a solid food. J Food Eng 91:56–63

McKenna BM, Lyng J, Brunton N, Shirsat N (2006) Advances in radio frequency and ohmic heating of meats. J Food Eng 77:215–229

Nikolopoulos CV, Tzanetis DE (2004) Estimates of blow-up time for a non-local reactive-convective problem modelling ohmic heating of foods. Proceedings of the Edinburgh Mathematical Society December 2004

Orangi S, Sastry SK, Li QA (1997) Numerical investigation of electroconductive heating in solid–liquid mixtures. Int J Heat Mass Trans 41:2211–2220

Orfeuil M (1987) Electric process heating: technologies/equipment/applications. Battelle, Columbus

Palaniappan S, Sastry SK (1991) Electrical conductivities of selected foods during ohmic heating. J Food Process Eng 14:221–236

Parrott DL (1992) Use of ohmic heating for aseptic processing of food particulates. Food Tech 46(245):239–241

Pataro G, Donsì G, Ferrari G (2011) Aseptic processing of apricots in syrup by means of a continuous pilot scale ohmic unit. LWT–Food Sci Tech 44:1546–1554

Perchonok M, Bourland C (2002) NASA food systems: past, present, and future. Nutr 18:913–920

Pereira R, Martins J, Mateus C, Teixeira JA, Vicente AA (2007) Death kinetics of Escherichia coli in goat milk and Bacillus licheniformis in cloudberry jam treated by ohmic heating. Chem Pap 61(2):121–126

Pesso T, Piva S (2009) Thermo-fluid analysis of a cylindrical collinear ohmic sterilizer in laminar flow Proceedings of ITP2009 Interdisciplinary Transport Phenomena VI: Fluid, Thermal, Biological, Materials and Space Sciences October 4–9, 2009, Volterra, Italy

Piette G, Buteau ME, Halleux D, Chiu L, Raymond Y, Ramaswany HS (2004) Ohmic cooking of processed meats and its effects on product quality. J Food Sci 69:71–78

Quarini GL (1995) Thermalhydraulic aspects of the ohmic heating process. J Food Eng 24:561–574

Ramaswamy HS, Abdelrahim KA, Simpson BK, Smith JP (1995) Residence time distribution (RTD) in aseptic processing of particulate foods: a review. Food Res Int 28(3):291–310

Roberts J, Balaben M, Luziriaga D (1996) Automated ohmic thawing of shrimp blocks. Seafood science and technology Society of the America (1996), pp 72–81

Samaranayake CP, Sastry SK (2005) Electrode and pH effects on electrochemical reactions during ohmic heating. J Electroanal Chem 577:125–135

Sandrine C, Eliot-Godéreauxa, François Zuberb, Goullieux A (2001) Processing and stabilisation of cauliflower by ohmic heating technology. Innov Food Sci Emerging Technol 2Ž 2001: 279–287

Sarang S, Sastry SK, Knipe L (2008) Electrical conductivity of fruits and meats during ohmic heating. J Food Eng 87:351–356

Sastry SK (1992) A model for heating of liquid-particle mixtures in a continuous flow ohmic heater. J Food Process Eng 15:263–278

Sastry SK (1997) Measuring residence time and modeling the system. Food Tech 51(10):44–48

Sastry SK, Cornelius BD (2002) Aseptic processing of foods containing solid particulates. John Wiley and Sons, Inc, New York

Sastry SK, Palaniappan S (1992) Ohmic heating of liquid–particle mixtures. Food Tech 46(12):68–72

Schreier P, Reid D, Fryer P (1993) Enhanced diffusion during the electrical heating of foods. Int J Food Sci Tech 28:249–260

Segner WP, Ragusa TJ, Marcus CL, Soutter EA (1989) Biological evaluation of a heat transfer simulation for sterilizing low-acid large particulate foods for aseptic packaging. J Food Process Preserve 13:257–274

Shim JY, Lee SH, Jun S (2010) Modeling of ohmic heating patterns of multiphase food products using computational fluid dynamics codes. J Food Eng 99:136–141

Shirsat N, Lyng JG, Brunton NP, McKenna B (2004) Ohmic processing: electrical conductivities of pork cuts. Meat Sci 67:507–514

Shynkaryk M, Sastry SK (2012) Simulation and optimization of the ohmic processing of highly viscous food product in chambers with sidewise parallel electrodes. J Food Eng 110:448–456

Skudder PJL (1992) Long life products by ohmic heating. Int Food Ingre 4:36–41

Skudder P, Biss C (1987) Aseptic processing of food products using ohmic heating. Chem Eng 2:26–28

Stirling R (1987) Ohmic heating-a new process for the food industry. J Power Eng 6:365–371

Takhistov P (2007) Dimensionless analysis of the electric field based food processes for scale-up and validation. J Food Eng 78:746–754

Toyoda IA (1994) Computational model for reaction fouling from whey protein solutions. Fouling and cleaning in food processing. Jesus College Cambridge, 23–25. March, 1994, pp 222–229. ISBN 92-827-4360-8

Tucker GS, Withers PM (1994) Determination of residence time distribution of nonsettling food particulates in viscous food carrier fluids using Hall effect sensors. J Food Process Eng 17:401–422

Tulsiyan P, Sarang S, Sastry SK (2008) Electrical conductivity of multi component systems during ohmic heating. Int J Food Prop 11:233–241

USA-FDA. United States of America, Food and Drug Administration, Center for Food Safety and Applied Nutrition Kinetics of microbial inactivation for alternative food processing technologies: ohmic and inductive heating 2000. http://www.cfsan.fda.gov/wcomm/ IFT-OHM. html. at: February 17th, 2009. Accessed on 14/08/2011

Wang W, Sastry S (1993a) Salt diffusion into vegetable tissue as a pre-treatment for ohmic heating: electrical conductivity profiles and vacuum infusion studies. J Food Eng 20:299–309

Wang W, Sastry S (1993b) Salt diffusion into vegetable tissue as a pretreatment for ohmic heating: determination of parameters and mathematical model verification. J Food Eng 20:311–323

Wang W, Sastry S (2000) Effects of thermal and electrotermal pretreatments on hot air drying rate of vegetable tissue. J Food Process Eng 23(4):299–319

Ward DR, Price RJ (1992) Food microbiology: exact use of an inexact science. In The NFI Green Book, vol 3, pp 34–42. National Fisheries Institute, Washington, DC. 1992

Weaver JC (1987) Transient aqueous pores: a mechanism for coupling electric fields to bilayer and cell membranes. In: Blank M, Findl E (eds) Mechanistic approaches to interactions of electric and electromagnetic fields with living systems. Plenum Press, New York, pp 249–270

Wills TM, de Witt CAM, Sigfusson H, Bellmer D (2006) Effect of cooking method and ethanolic tocopherol on oxidative stability and quality of beef patties during refrigerated storage (oxidative stability of cooked patties). J Food Sci 71:109–114

Wu H, Kolbe E, Flugstad B, Park JW, Yongsawatdigul J (1998) Electrical properties of fish mince during multi-frequency ohmic heating. J Food Sci 63(6):1029–1032

Yang TCS, Cohen JS, Kluter RA, Tempest P, Manvell C, Blackmore SJ, Adams S (1997) Microbiological and sensory evaluation of six ohmically heated stew type products. J Food Qual 20:303–313

Zell M, Cronin DA, Morgan DJ, Marra F, Lyng JG (2008) Solid food pasteurization by ohmic heating: influence of process parameters excerpt from the proceedings of the COMSOL Conference Boston. 2008

Zell M, Lyng JG, Cronin DA, Morgan DJ (2009) Ohmic heating of meats: electrical conductivities of whole meats and processed meat ingredients. Meat Sci 83:563–570

Zell M, Lyng JG, Cronin DA, Morgan DJ (2010) Ohmic cooking of whole beef muscle—evaluation of the impact of a novel rapid ohmic cooking method on product quality. Meat Sci 86:258–264

Zhang L, Fryer PJ (1993) Models for the electrical heating of solid–liquid mixtures. Chem Eng Sci 48:633–643

Zhao Y, Flugstad B, Kolbe E, Park JW, Well JH (2000) Using capacitative (radiofrequency) dielectric heating in food processing and preservation. J Food Process Eng 23:25–50

Zhong T, Lima M (2003) The effect of ohmic heating on vacuum drying rate of sweet potato tissue. Bioresour Technol 87:215–220

Zoltai P, Swearingen P (1996) Product development considerations for ohmic processing. Food Tech 50:263–266

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Varghese, K.S., Pandey, M.C., Radhakrishna, K. et al. Technology, applications and modelling of ohmic heating: a review. J Food Sci Technol 51, 2304–2317 (2014). https://doi.org/10.1007/s13197-012-0710-3

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-012-0710-3