Abstract

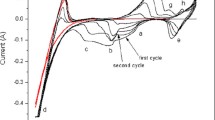

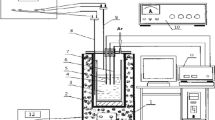

V2O5 sintered pellets and graphite rods were employed as the cathode and the anode, respectively; a molten CaCl2-NaCl salt was used as the electrolyte. Then, V2O5 was directly reduced to metal vanadium by the Fray-Farthing-Chen (FFC) method at 873 K to realize low-temperature electrolysis. Two typical experimental conditions, electrolysis time and voltage, were taken into account to investigate the current efficiency and remaining oxygen content in electrolyzed products. The composition and microstructure of the products were characterized by X-ray diffraction (XRD) and scanning electron microscopy (SEM). SEM observations show that a higher voltage (1.8–3.4 V) and a longer electrolysis time (2–5 h) can improve the product quality separately, that is, a lower remaining oxygen content and a more uniform microstructure. The products with an oxygen content of 0.205wt% are successfully obtained below 3.4 V for 10 h. However, the current efficiency is low, and further work is required.

Similar content being viewed by others

References

D.X. Huang, Vanadium Extracting and Steelmaking, Metallurgy Industry Press, Beijing, 2000, p.48.

L.J. Lozano and D. Juan, Leaching of vanadium from spent sulphuric acid catalysts, Miner. Eng., 14(2001), No.5, p.543.

C.K. Gupta, The aluminothermic process for vanadium production, [in] Vanadium-Geology, Processing and Applications, Montreal, 2002, p.205.

X.Y. Xin and S.J. Li, Progress in the research of vanadium metal preparation, Sichuan Nonferrous Met., 11(2009), No.1, p.11.

S.Z. Yang, Vanadium Metallurgy, Metallurgy Industry Press, Beijing, 2010, p.136.

P.K. Tripathy and A.K. Suri, A new process for the preparation of vanadium metal, High Temp. Mater. Processes, 21(2002), No.3, p.127.

G.Z. Chen, D.J. Fray, and T.W. Farthing, Direct electrochemical reduction of titanium dioxide to titanium in molten calcium chloride, Nature, 407(2000), No.6802, p.361.

D.J. Fray and G.Z. Chen, Reduction of titanium and other metal oxides using electrodeoxidation, Mater. Sci. Technol., 20(2004), No.3, p.295.

D.T.L. Alexander, C. Schwandt, and D.J. Fray, Microstructural kinetics of phase transformations during electrochemical reduction of titanium dioxide in molten calcium chloride, Acta Mater., 54(2006), No.11, p.2933.

X.M. Nie, L.Y. Dong, C.G. Bai, D.F. Chen, and G.B. Qiu, Preparation of Ti by direct electrochemical reduction of solid TiO2 and its reaction mechanism, Trans. Nonferrous Met. Soc. China, 16(2006), Suppl., p.s723.

G.Z. Chen, E. Gordo, and D.J. Fray, Direct electrolytic preparation of chromium powder, Metall. Mater. Trans. B, 35(2004), No.2, p.223.

E. Gordo, G.Z. Chen, and D.J. Fray, Toward optimization of electrolytic reduction of solid chromium oxide to chromium powder in molten chloride salts, Electrochim. Acta, 49(2004), No.13, p.2195.

X.Y. Yan and D.J. Fray, Electrochemical studies on reduction of solid Nb2O5 in molten CaCl2-NaCl eutectic: I. Factors affecting electrodeoxidation of solid Nb2O5 to niobium, J. Electrochem. Soc., 152(2005), No.1, p.D12.

X.Y. Yan and D.J. Fray, Using electro-deoxidation to synthesize niobium sponge from solid Nb2O5 in alkali-alkaline-earth metal chloride melts, J. Mater. Res., 18(2003), No.2, p.346.

R.O. Suzuki and H. Ishikawa, Direct reduction of vanadium oxide in molten CaCl2, Trans. Inst. Min. Metall. Sect. C, 117(2008), No.2, p.108.

H.A. Wriedt, The O-V (oxygen-vanadium) system, Bull. Alloy Phase Diagrams, 10(1989), No.3, p.271.

Author information

Authors and Affiliations

Corresponding author

Additional information

This work was financially supported by the Major State Basic Research and Development Program of China (No.2007CB613504).

Rights and permissions

About this article

Cite this article

Cai, Zf., Zhang, Zm., Guo, Zc. et al. Direct electrochemical reduction of solid vanadium oxide to metal vanadium at low temperature in molten CaCl2-NaCl. Int J Miner Metall Mater 19, 499–505 (2012). https://doi.org/10.1007/s12613-012-0586-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-012-0586-2