Abstract

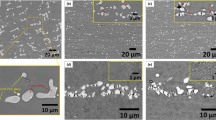

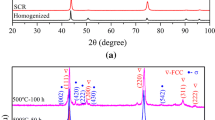

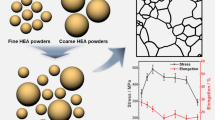

Cold rolling and post-deformation annealing (PDA) heat treatments were used to produce heterogeneous grain structures (HGS) in a single-phase face-centered cubic (fcc) Cr10Co30Fe30Ni30 high-entropy alloy (HEA). The microstructural evolution and microstructure–property relationship of the HEA were systematically studied under different states. HGS could be achieved in PDA-treated samples at 875 °C for 20 s and at 900 °C for 20 s (PDA-900-20 s). PDA-900-20 s sample exhibits the most excellent combination of strength and ductility, showing a tensile yield strength of ~ 590 MPa, an ultimate strength of ~ 706 MPa and a total elongation of ~ 23.9%. Additionally, compared with the homogenized counterpart exhibiting homogenous grains, PDA-900-20 s sample displays a notable increment of ~ 413% in yield strength and simultaneously maintains a good ductility. The dominated strengthening mechanisms in PDA-900-20 s sample are grain-boundary strengthening and heterogeneous deformation-induced (HDI) strengthening, whereas the good ductility is mainly resulted from the HDI ductility. Accordingly, the present study provides an effective and simple pathway to overcome the strength–ductility trade-off of typical fcc HEAs through heterogeneous microstructure.

Graphical abstract

摘要

本文采用冷轧和变形后退火热处理(PDA)在单相面心立方(fcc) Cr10Co30Fe30Ni30高熵合金(HEA)中成功获得了异质晶粒结构(HGS)。系统研究了该HEA在不同状态下的组织演化和性能关系。该合金在875 °C, 20 s和900 °C,20 s (PDA-900-20 s) PDA处理后均获得了异质晶粒组织。PDA-900-20 s样品的强度和塑性匹配最佳, 其屈服强度约为590 MPa, 抗拉强度约为706 MPa, 伸长率约为23.9%。与均匀晶粒结构的均质态样品相比, PDA-900-20 s样品的屈服强度显著提高了约413%, 同时保持了良好的塑性。PDA-900-20 s的强化机制主要为晶界强化和非均匀变形诱导(HDI)强化, 良好的塑性主要来源于HDI诱导塑性。本文通过引入异质晶粒组织, 为fcc高熵合金克服强度-塑性倒置提供了一种有效且简单的方法。

Similar content being viewed by others

References

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6(5):299.

Cantor B, Chang ITH, Knight P, Vincent AJB. Microstructural development in equiatomic multicomponent alloys. Mater Sci Eng A. 2004;375–377:213.

Tong C, Chen M, Chen S, Yeh J, Shun T, Lin S, Chang S. Mechanical performance of the AlxCoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A. 2005;36(5):1263.

Tsai M, Tsai R, Chang T, Huang W. Intermetallic phases in high-entropy alloys: statistical analysis of their prevalence and structural inheritance. Metals. 2019;9(2):247.

Lu S, Miao J, Lu Y. Strengthening and toughening of multi-principal high-entropy alloys. Chin J Rare Met. 2021;45(5):530.

Chu CL, Chen WP, Chen Z, Jiang ZF, Wang H, Fu ZQ. Microstructure and mechanical behavior of FeNiCoCr and FeNiCoCrMn high-entropy alloys fabricated by powder metallurgy. Acta Metall. Sin. (Engl. Lett.). 2021;34:445.

Fu Z, Jiang L, Wardini JL, MacDonald BE, Wen H, Xiong W, Zhang D, Zhou Y, Rupert TJ, Chen W, Lavernia EJ. A high-entropy alloy with hierarchical nanoprecipitates and ultrahigh strength. Sci. Adv. 2018;4(10):eaat8712.

Niu S, Kou H, Wang J, Li J. Improved tensile properties of Al0.5CoCrFeNi high-entropy alloy by tailoring microstructures. 2021;40(9):2508.

Sathiyamoorthi P, Asghari-Rad P, Park JM, Moon J, Bae JW, Zargaran A, Kim HS. Exceptional cryogenic strength-ductility synergy in Al0.3CoCrNi medium-entropy alloy through heterogeneous grain structure and nano-scale precipitates. Mater. Sci. Eng. A, 2019;766:138372.

Cheng H, Fang Y, Xu J, Zhu C, Dai P, Xue S. Tribological properties of nano/ultrafine-grained FeCoCrNiMnAlx high-entropy alloys over a wide range of temperatures. J Alloys Compd. 2020;817:153305.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448.

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Science. 2014;345:1153.

Laurent-Brocq M, Akhatova A, Perrière L, Chebini S, Sauvage X, Leroy E, Champion Y. Insights into the phase diagram of the CrMnFeCoNi high entropy alloy. Acta Mater. 2015;88:355.

Li P, Wang A, Liu CT. Composition dependence of structure, physical and mechanical properties of FeCoNi(MnAl)x high entropy alloys. Intermetallics. 2017;87:21.

Salishchev GA, Tikhonovsky MA, Shaysultanov DG, Stepanov ND, Kuznetsov AV, Kolodiy IV, Tortika AS, Senkov ON. Effect of Mn and V on structure and mechanical properties of high-entropy alloys based on CoCrFeNi system. J Alloys Compd. 2014;591:11.

Otto F, Dlouhý A, Somsen C, Bei H, Eggeler G, George EP. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013;61:5743.

Yoshida S, Bhattacharjee T, Bai Y, Tsuji N. Friction stress and Hall-Petch relationship in CoCrNi equi-atomic medium entropy alloy processed by severe plastic deformation and subsequent annealing. Scripta Mater. 2017;134:33.

Wu X, Yang M, Yuan F, Wu G, Wei Y, Huang X, Zhu Y. Heterogeneous lamella structure unites ultrafine-grain strength with coarse-grain ductility. Proc Natl Acad Sci USA. 2015;112(47):14501.

Niu G, Wu H, Zhang D, Gong N, Tang D. Heterogeneous nano/ultrafine-grained medium Mn austenitic stainless steel with high strength and ductility. Mater Sci Eng A. 2018;725:187.

Wang Q, Xin C, Sun Q, Xiao L, Sun J. Biaxial tension-torsion fatigue behavior of gradient nano-grained pure titanium fabricated by surface nanocrystallization. Mater Sci Eng A. 2017;702:125.

Won JW, Lee T, Hong S, Lee Y, Lee JH, Lee CS. Role of deformation twins in static recrystallization kinetics of high-purity alpha titanium. Met Mater Int. 2016;22(6):1041.

Wang ZW, Lu WJ, Zhao H, Liebscher CH, He JY, Ponge D, Raabe D, Li ZM. Ultrastrong lightweight compositionally complex steels via dual-nanoprecipitation. Sci Adv. 2020;6(46):eaba9543.

Wang ZW, Gu J, An DY, Liu Y, Song M. Characterization of the microstructure and deformation substructure evolution in a hierarchal high-entropy alloy by correlative EBSD and ECCI. Intermetallics. 2020;121:106788.

Fu Z, MacDonald BE, Zhang D, Wu B, Chen W, Ivanisenko J, Hahn H, Lavernia EJ. Fcc nanostructured TiFeCoNi alloy with multi-scale grains and enhanced plasticity. Scr Mater. 2018;143:108.

Gu J, Ni S, Liu Y, Song M. Regulating the strength and ductility of a cold rolled FeCrCoMnNi high-entropy alloy via annealing treatment. Mater Sci Eng A. 2019;755:289.

He QF, Ye YF, Yang Y. Formation of random solid solution in multicomponent alloys: from Hume-Rothery rules to entropic stabilization. J Phase Equilib Diff. 2017;38:416.

Gao MC, Zhang C, Gao P, Zhang F, Ouyang LZ, Widom M, Hawk JA. Thermodynamics of concentrated solid solution alloys. Curr Opin Solid St M. 2017;21(5):238.

Poletti MG, Battezzati L. Electronic and thermodynamic criteria for the occurrence of high entropy alloys in metallic systems. Acta Mater. 2014;75:297.

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP. Microstructures and properties of high-entropy alloys. Prog Mater Sci. 2014;61:1.

Rollett A, Humphreys F, Rohrer GS, Hatherly M. Recrystallization and Related Annealing Phenomena. Amsterdam: Elsevier; 2004. 221.

Wełnic W, Kalb JA, Wamwangi D, Steimer C, Wuttig M. Phase change materials: from structures to kinetics. J Mater Res. 2007;22:2368.

Wu Z, Bei H, Pharr GM, George EP. Temperature dependence of the mechanical properties of equiatomic solid solution alloys with face-centered cubic crystal structures. Acta Mater. 2014;81:428.

Lu Y, Molodov DA, Gottstein G. Recrystallization kinetics and microstructure evolution during annealing of a cold-rolled Fe–Mn–C alloy. Acta Mater. 2011;59:3229.

Hou J, Zhang M, Yang H, Qiao J. Deformation behavior of Al0.25CoCrFeNi high-entropy alloy after recrystallization. Metals. 2017;7:111.

Wang Z, Baker I, Guo W, Poplawsky JD. The effect of carbon on the microstructures, mechanical properties, and deformation mechanisms of thermo-mechanically treated Fe40.4Ni11.3Mn34.8Al7.5Cr6 high entropy alloys. Acta Mater. 2017;126:346.

Liu WH, Lu ZP, He JY, Luan JH, Wang ZJ, Liu B, Liu Y, Chen MW, Liu CT. Ductile CoCrFeNiMox high entropy alloys strengthened by hard intermetallic phases. Acta Mater. 2016;116:332.

Daoud HM, Manzoni A, Völkl R, Wanderka N, Glatzel U. Microstructure and tensile behavior of Al8Co17Cr17Cu8Fe17Ni33 (at%) high-entropy alloy. JOM. 2013; 65(12): 1805.

Niu S, Kou H, Guo T, Zhang Y, Wang J, Li J. Strengthening of nanoprecipitations in an annealed Al0.5CoCrFeNi high entropy alloy. Mater Sci Eng A. 2016;671:82.

Wang Z, Baker I. Effects of annealing and thermo-mechanical treatment on the microstructures and mechanical properties of a carbon-doped FeNiMnAl multi-component alloy. Mater Sci Eng A. 2017;693:101.

Zuo T, Ren S, Liaw PK, Zhang Y. Processing effects on the magnetic and mechanical properties of FeCoNiAl0.2Si0.2 high entropy alloy. Int J Min Met Mater. 2013;20(6):549.

Chen J, Yao Z, Wang X, Lu Y, Wang X, Liu Y, Fan X. Effect of C content on microstructure and tensile properties of as-cast CoCrFeMnNi high entropy alloy. Mater Chem Phys. 2018;210:136.

Fu Z, MacDonald BE, Li Z, Jiang Z, Chen W, Zhou Y, Lavernia EJ. Engineering heterostructured grains to enhance strength in a single-phase high-entropy alloy with maintained ductility. Mater Res Lett. 2018;6(11):634.

He F, Chen D, Han B, Wu Q, Wang Z, Wei S, Wei D, Wang J, Liu CT, Kai J. Design of D022 superlattice with superior strengthening effect in high entropy alloys. Acta Mater. 2019;167:275.

Zhu Y, Wu X. Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater Res Lett. 2019;7(10):393.

Yang M, Pan Y, Yuan F, Zhu Y, Wu X. Back stress strengthening and strain hardening in gradient structure. Mater Res Lett. 2016;4(3):145.

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater. 2014;62:105.

Chu CL, Hao LY, Chen WP, Xiong W, Niu JC, Fu ZQ. Phase transformations and mechanical behavior in a non-equiatomic Ti10Fe30Co30Ni30 medium-entropy alloy. Mater Sci Eng A. 2022;832:142429.

Yang H, Li J, Guo T, Wang W, Kou H, Wang J. Evolution of microstructure and hardness in a dual-phase Al0.5CoCrFeNi high-entropy alloy with different grain sizes. Rare Met. 2020;39(2):156.

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China (No. 52103360), the Basic and Applied Basic Research Foundation of Guangdong Province (No. 2020A1515111104) and the Key-Area Research and Development Program of Guangdong Province (No. 2018B090905002).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chu, CL., Chen, WP., Liu, JC. et al. Achieving strength–ductility synergy in a non-equiatomic Cr10Co30Fe30Ni30 high-entropy alloy with heterogeneous grain structures. Rare Met. 41, 2864–2876 (2022). https://doi.org/10.1007/s12598-022-02019-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-022-02019-9