Abstract

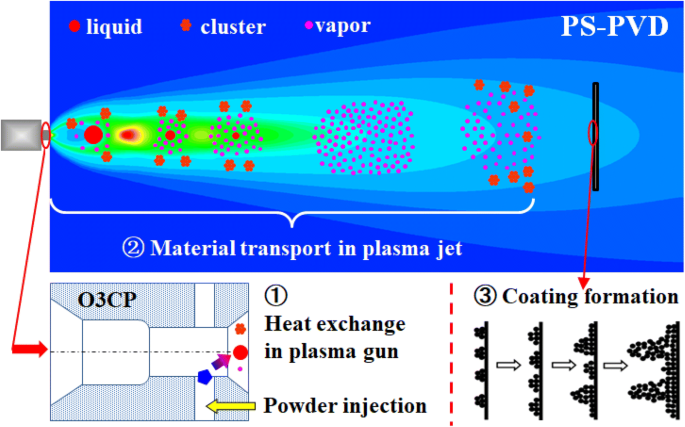

Plasma spray–physical vapor deposition (PS–PVD) is a unique technology that enables highly tailorable functional films and coatings with various rare metal elements to be processed. This technology bridges the gap between conventional thermal spray and vapor deposition and provides a variety of coating microstructures composed of vapor, liquid, and solid deposition units. The PS–PVD technique serves a broad range of applications in the fields of thermal barrier coatings (TBCs), environmental barrier coatings (EBCs), oxygen permeable films, and electrode films. It also represents the development direction of high-performance TBC/EBC preparation technologies. With the PS–PVD technique, the composition of the deposition unit determines the microstructure of the coating and its performance. When coating materials are injected into a nozzle and transported into the plasma jet, the deposition unit generated by a coating material is affected by the plasma jet characteristics. However, there is no direct in situ measurement method of material transfer and deposition processes in the PS–PVD plasma jet, because of the extreme conditions of PS–PVD such as a low operating pressure of ~ 100 Pa, temperatures of thousands of degrees, and a thin and high-velocity jet. Despite the difficulties, the transport and transformation behaviors of the deposition units were also researched by optical emission spectroscopy, observation of the coating microstructure and other methods. This paper reviews the progress of PS–PVD technologies considering the preparation of advanced thermal barrier coatings from the perspective of the transport and transformation behaviors of the deposition units. The development prospects of new high-performance TBCs using the PS–PVD technique are also discussed.

Graphic abstract

Similar content being viewed by others

References

Padture NP, Gell M, Jordan EH. Thermal barrier coatings for gas-turbine engine applications. Science. 2002;296(5566):280.

Padture NP. Advanced structural ceramics in aerospace propulsion. Nat Mater. 2016;15(8):804.

Li GR, Xie H, Yang GJ, Liu G, Li CX, Li CJ. A comprehensive sintering mechanism for TBCs-Part I: an overall evolution with two-stage kinetics. J Am Ceram Soc. 2017;100(5):2176.

Li GR, Xie H, Yang GJ, Liu G, Li CX, Li CJ. A comprehensive sintering mechanism for TBCs-part II: multiscale multipoint interconnection enhanced initial kinetics. J Am Ceram Soc. 2017;100(9):4240.

Li GR, Yang GJ, Li CX, Li CJ. A comprehensive sintering mechanism for TBCs-Part III: substrate constraint effect on healing of 2D pores. J Am Ceram Soc. 2018;101(8):3636.

Cheng B, Yang N, Zhang Q, Zhang M, Zhang YM, Chen L, Yang GJ, Li CX, Li CJ. Sintering induced the failure behavior of dense vertically crack and lamellar structured TBCs with equivalent thermal insulation performance. Ceram Int. 2017;43(17):15459.

Cheng B, Zhang YM, Yang N, Zhang M, Chen L, Yang GJ, Li CX, Li CJ. Sintering-induced delamination of thermal barrier coatings by gradient thermal cyclic test. J Am Ceram Soc. 2017;100(5):1820.

Li GR, Cheng B, Yang GJ, Li CX. Strain-induced stiffness-dependent structural changes and the associated failure mechanism in TBCs. J Eur Ceram Soc. 2017;37(11):3609.

Renteria F, Saruhan B, Schulz U, Scheibe R, Haug J, Wiedenmann A. Effect of morphology on thermal conductivity of EB–PVD PYSZ TBCs. Surf Coat Technol. 2006;201(6):2611.

Song C, Qu SJ, Liang J, Han JC. Effects of heat treatment on mechanical properties of ODS nickel-based superalloy sheets prepared by EB–PVD. Rare Met. 2011;30(1):76.

Yue S, Xiu L, He X, Zhang J, Li M, Song G, Li X, Zhao Y. Effects of substrate rotation on the microstructure of metal sheet fabricated by electron beam physical vapor deposition. Appl Surf Sci. 2009;255(11):5831.

Mauer G, Hospach A, Vassen R. Process development and coating characteristics of plasma spray–PVD. Surf Coat Technol. 2013;220:219.

von Niessen K, Gindrat M. Plasma spray–PVD: a new thermal spray process to deposit out of the vapor phase. J Therm Spray Technol. 2011;20(4):736.

Muehlberger E. Method of forming uniform thin coatings on large substrates. US Patent 5853815. 12. 1998.

Góral M, Sieniawski S, Kotowski M, Pytel M, Masłyk M. Influence of turbine blade geometry on thickness of TBCs deposited by VPA and PS–PVD methods. Arch Mat Sci Eng. 2012;54(1):22.

Rezanka S, Mauer G, Vassen R. Improved thermal cycling durability of thermal barrier coatings manufactured by PS–PVD. J Therm Spray Technol. 2014;23(1–2):182.

Mao J, Liu M, Deng CG, Deng CM, Zhou KS, Deng ZQ. Preparation and distribution analysis of thermal barrier coatings deposited on multiple vanes by plasma spray–physical vapor deposition technology. J Eng Mater-T ASME. 2017;139(4):041003.

Harder BJ, Zhu D. Plasma spray–physical vapor deposition (PS–PVD) of ceramics for protective coatings. Ceram Eng Sci Proc. 2011;32(3):73.

von Niessen K, Gindrat M, Refke A. Vapor phase deposition using plasma spray–pvd (TM). J Therm Spray Technol. 2010;19(1–2):502.

Vautherin B, Planche MP, Bolot R, Quet A, Bianchi L, Montavon G. Vapors and droplets mixture deposition of metallic coatings by very low pressure plasma spraying. J Therm Spray Technol. 2014;23(4):596.

Liu MJ, Zhang KJ, Zhang Q, Zhang M, Yang GJ, Li CX, Li CJ. Thermodynamic conditions for cluster formation in supersaturated boundary layer during plasma spray–physical vapor deposition. Appl Surf Sci. 2019;471:950.

Zhu L, Zhang NN, Zhang BC, Sun F, Bolot R, Planche MP, Liao HL, Coddet C. Very low pressure plasma sprayed alumina and yttria-stabilized zirconia thin dense coatings using a modified transferred arc plasma torch. Appl Surf Sci. 2011;258(4):1422.

Deng ZQ, Zhang XF, Zhou KS, Liu M, Deng CG, Mao J, Chen Z. 7YSZ coating prepared by PS–PVD based on heterogeneous nucleation. Chin J Aeronaut. 2018;31(4):820.

Goral M, Kotowski S, Nowotnik A, Pytel M, Drajewicz M, Sieniawski J. PS–PVD deposition of thermal barrier coatings. Surf Coat Technol. 2013;237:51.

Cao XQ, Vassen R, Stoever D. Ceramic materials for thermal barrier coatings. J Eur Ceram Soc. 2004;24(1):1.

Mauer G, Hospach A, Zotov N, Vassen R. Process conditions and microstructures of ceramic coatings by gas phase deposition based on plasma spraying. J Therm Spray Technol. 2013;22(2–3):83.

Hospach A, Mauer G, Vassen R, Stoever D. Characteristics of ceramic coatings made by thin film low pressure plasma spraying (LPPS-TF). J Therm Spray Technol. 2012;21(3–4):435.

Liu MJ, Zhang M, Zhang Q, Yang GJ, Li CX, Li CJ. Evaporation of droplets in plasma spray–physical vapor deposition based on energy compensation between self-cooling and plasma heat transfer. J Therm Spray Technol. 2017;26(7):1641.

Mauer G. Plasma characteristics and plasma-feedstock interaction under PS–PVD process conditions. Plasma Chem Plasma P. 2014;34(5):1171.

Liu MJ, Zhang M, Zhang Q, Yang GJ, Li CX, Li CJ. Gaseous material capacity of open plasma jet in plasma spray–physical vapor deposition process. Appl Surf Sci. 2018;428:877.

Anwaar A, Wei LL, Qian G, Zhang BP, Guo HB. Novel prospects for plasma spray–physical vapor deposition of columnar thermal barrier coatings. J Therm Spray Technol. 2017;26(8):1810.

Anwaar A, Wei LL, Guo HB. Plasma characteristics and coating microstructures of yttria stabilized zirconia during plasma spray physical vapor deposition. In: Proceedings of 2017 14th International Bhurban Conference on Applied Sciences and Technology, IEEE, New York, 2017. 4.

Anwaar A, Wei LL, Guo HB, Zhang BP. Plasma–powder feedstock interaction during plasma spray–physical vapor deposition. J Therm Spray Technol. 2017;26(3):292.

He W, Mauer G, Gindrat M, Waeger R, Vassen R. Investigations on the nature of ceramic deposits in plasma spray–physical vapor deposition. J Therm Spray Technol. 2017;26(1–2):83.

Li C, Guo HB, Gao LH, Wei LL, Gong SK, Xu HB. Microstructures of yttria-stabilized zirconia coatings by plasma spray–physical vapor deposition. J Therm Spray Technol. 2015;24(3):534.

Gao LH, Guo HB, Wei LL, Li C, Gong SK, Xu HB. Microstructure and mechanical properties of yttria stabilized zirconia coatings prepared by plasma spray physical vapor deposition. Ceram Int. 2015;41(7):8305.

Zhang XF, Zhou KS, Deng CM, Liu M, Deng ZQ, Deng CG, Song JB. Gas-deposition mechanisms of 7YSZ coating based on plasma spray–physical vapor deposition. J Eur Ceram Soc. 2016;36(3):697.

Chen QY, Peng XZ, Yang GJ, Li CX, Li CJ. Characterization of plasma jet in plasma spray–physical vapor deposition of ysz using a < 80 kW shrouded torch based on optical emission spectroscopy. J Therm Spray Technol. 2015;24(6):1.

Mauer G, Vassen R. Plasma spray–PVD: plasma characteristics and impact on coating properties. In: 12th High-Tech Plasma Processes Conference, Bologna, 2012. 406.

He WT, Mauer G, Vassen R. Excitation temperature and constituent concentration profiles of the plasma jet under plasma spray–pvd conditions. Plasma Chem Plasma P. 2017;37(5):1293.

Ovsyannikov AA, Zhukov MF. Plasma Diagnostics. Cambridge: Cambridge International Science; 1995. 520.

Joshi NK, Sahasrabudhe SN, Sreekumar KP, Venkatramani N. Axial variation of electron number density in thermal plasma spray jets. Eur Phys J D. 2003;26(2):215.

Zhang NN, Sun F, Zhu L, Planche MP, Liao HL, Dong C, Coddet C. Electron temperature and density of the plasma measured by optical emission spectroscopy in VLPPS conditions. J Therm Spray Technol. 2011;20(6):1321.

Griem HR. Plasma Spectroscopy. New York: McGraw-Hill; 1964. 864.

Cui JH, Xu ZF, Zhang JL, Nie QY, Xu GH, Ren LL. Online diagnosis of electron excitation temperature in CH4 + H2 discharge plasma at atmospheric pressure by optical emission spectra. Sci China. 2008;51(12):1892.

Zhang NN, Sun F, Zhu L, Verdy C, Planche MP, Liao HL, Dong C, Coddet C. Characteristics of Cu film deposited using VLPPS. J Therm Spray Technol. 2010;20(1–2):351.

Liu Mj. Cross-Domain Transport Mechanism of Materials and Integrated Control of Parameter-Group During Plasma Spray–Physical Vapor Deposition. Xi’an Jiaotong University. 2018, 80.

Mauer G, Vassen R. Conditions for nucleation and growth in the substrate boundary layer at plasma spray–physical vapor deposition (PS–PVD). Surf Coat Technol. 2019;371(SI):417.

Zhang XF, Zhou KS, Song JB, Deng CM, Niu SP, Deng ZQ. Deposition and CMAS corrosion mechanism of 7YSZ thermal barrier coatings prepared by plasma spray–physical vapor deposition. J Inorg Mater. 2015;30(3):287.

Zhang XF, Zhou KS, Liu M, Deng CM, Deng ZQ, Chen BY. Toughness and elasticity behaviors in nano-structured 7 wt% Y2O3-stabilized ZrO2 coating. Surf Coat Technol. 2015;276:316.

Deng ZQ, Liu M, Mao J, Deng CM, Zhang XF. Stage growth of columnar 7YSZ coating prepared by plasma spray–physical vapor deposition. Vacuum. 2017;145:39.

Zhang XF, Zhou KS, Liu M, Deng CM, Niu SP, Xu SM. Preparation of Si/Mullite/Yb2SiO5 environment barrier coating (EBC) by plasma spray–physical vapor deposition (PS–PVD). J Inorg Mater. 2018;33(3):325.

Zhang XF, Zhou KS, Liu M, Deng CM, Deng CG, Mao J, Deng ZQ. Mechanisms governing the thermal shock and tensile fracture of PS–PVD 7YSZ TBC. Ceram Int. 2018;44(4):3973.

Zhang XF, Zhou KS, Liu M, Deng CG, Deng CM, Niu SP, Xu SM, Su YF. CMAS corrosion and thermal cycle of Al-modified PS–PVD environmental barrier coating. Ceram Int. 2018;44(13):15959.

Gao LH, Guo HB, Wei LL, Li CY, Xu HB. Microstructure, thermal conductivity and thermal cycling behavior of thermal barrier coatings prepared by plasma spray–physical vapor deposition. Surf Coat Technol. 2015;276:424.

Gao LH, Wei LL, Guo HB, Gong SK, Xu HB. Deposition mechanisms of yttria-stabilized zirconia coatings during plasma spray–physical vapor deposition. Ceram Int. 2016;42(4):5530.

Zhang BP, Wei LL, Guo HB, Xu HB. Microstructures and deposition mechanisms of quasi-columnar structured yttria-stabilized zirconia coatings by plasma spray–physical vapor deposition. Ceram Int. 2017;43(15):12920.

Yang XL, Wei LL, Li JM, Zhang BP, Wang SX, Guo HB. Microstructural evolution of plasma spray–physical vapor deposited thermal barrier coatings at 1150 °C studied by impedance spectroscopy. Ceram Int. 2018;44(9):10797.

Zhang BP, Song WJ, Guo HB. Wetting, infiltration and interaction behavior of CMAS towards columnar YSZ coatings deposited by plasma spray–physical vapor. J Eur Ceram Soc. 2018;38(10):3564.

Shi J, Wei LL, Zhang BP, Gao LH, Guo HB, Gong SK, Xu HB. Research process in plasma spray–physical vapor deposited thermal barrier coatings. J Aero Mate. 2018;38(2):1.

Li GR, Wang LS. Durable TBCs with self-enhanced thermal insulation based on co-design on macro- and microstructure. Appl Surf Sci. 2019;483:472.

Li GR, Yang GJ. Understanding of degradation-resistant behaviour of nanostructured thermal barrier coatings with bimodal structure. J Mater Sci Technol. 2019;35(3):231.

Li GR, Wang LS, Yang GJ. A novel composite-layered coating enabling self-enhancing thermal barrier. Scr Mater. 2019;163(1):142.

Acknowledgements

This work was financially supported by the National Key R&D Plan (No. 2017YFB0306103), the Fundamental Research Funds for the Central Universities, and the National Program for Support of Top-notch Young Professionals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, MJ., Zhang, G., Lu, YH. et al. Plasma spray–physical vapor deposition toward advanced thermal barrier coatings: a review. Rare Met. 39, 479–497 (2020). https://doi.org/10.1007/s12598-019-01351-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12598-019-01351-x