Abstract

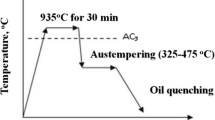

The ferrite–bainite microstructures and mechanical properties in a hot-rolled dual phase steel with different transformation temperatures were investigated in this paper. The deformation behavior of bainite and ferrite was analyzed by using in situ scanning electron microscope. The results showed that the ferrite and bainite can be refined and the volume fraction of bainite can be slightly increased by 5% by decreasing the ferrite transformation temperature from 690 to 635 °C and increasing the bainite transformation temperature from 400 to 450 °C. The strengthening mechanism was dislocation difference in polygonal and acicular ferrite and then the grain size difference of ferrite. The hole expansion ratio increased from 52.9 to 83.7% with the ferrite transformation temperature decreasing. The cracks or voids were smaller in size and also the number in steel with the lower ferrite transformation temperature after expanding. The microstructure separation along the boundary between bainite and ferrite and the slip band in the ferrite appeared at the non-uniform deformation stage. However, fewer appeared in the microstructure of steel with lower ferrite transformation temperature. Cooperative deformation of ferrite and bainite and finer microstructure in steel with lower ferrite transformation temperature were the mechanisms why the cracks could not easily nucleated and propagated, respectively. Thus this was also why there was a better hole expansion ratio.

Graphic Abstract

The ferrite–bainite microstructures and mechanical properties in a hot-rolled dual phase steel with different transformation temperatures were investigated. The deformation behavior of bainite and ferrite was analyzed by using in situ scanning electron microscope. The strengthening mechanism was dislocation difference in polygonal and acicular ferrite and then the grain size difference of ferrite. The hole expansion ratio increased from 52.9 to 83.7%. Cooperative deformation of ferrite and bainite and finer microstructure in steel with lower ferrite transformation temperature were the mechanisms why the cracks could not easily nucleated and propagated, respectively. Thus this was also why there was a better hole expansion ratio.

Similar content being viewed by others

References

Y.L. Kang, Lightweight vehicle, advanced high strength steel and energy-saving and emission reduction. Iron Steel 43(6), 1–7 (2008) (in chinese)

A. Kumar, S.B. Singh, K.K. Ray, Influence of bainite/martensite-content on the tensile properties of low carbon dual-phase steels. Mater. Sci. Eng. A 474(1–2), 270–282 (2008)

S.H. Choi, E.Y. Kim, S.I. Kim, The micromechanical deformation behaviors of hot-rolled 590FB steel during hole-expansion test. Int. J. Plast 58, 184–200 (2014)

S. Hashimoto, M. Sudo, K. Mimura et al., Effect of microstructure on mechanical properties of C-Mn high strength hot rolled sheet steel. Trans. Iron Steel Inst. Jpn. 26(11), 985–992 (1986)

J. Lee, S.J. Lee, B.C. De Cooman, Effect of micro-alloying elements on the stretch-flangeability of dual phase steel. Mater. Sci. Eng. A 536, 231–238 (2012)

A. Kamp, S. Celotto, D.N. Hanlon, Effects of tempering on the mechanical properties of high strength dual-phase steels. Mater. Sci. Eng. A 538, 35–41 (2012)

I. Pushkareva, S. Allain, C. Scott et al., Relationship between microstructure, mechanical properties and damage mechanisms in high martensite fraction dual phase steels, in ISIJ International. ISIJINT-2015-186 (2015)

J.I. Yoon, J. Jung, H.H. Lee et al., Relationships between stretch-flangeability and microstructure-mechanical properties in ultra-high-strength dual-phase steels. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00270-x

Y.R. Cho, J.H. Chung, H.H. Ku et al., Effect of controlled cooling on the formability of TS 590 MPa grade hot-rolled high strength steels. Met. Mater. 5(6), 571–578 (1999)

D.I. Hyun, S.M. Oak, S.S. Kang et al., Estimation of hole flangeability for high strength steel plates. J. Mater. Process. Technol. 130, 9–13 (2002)

J. Lee, S.J. Lee, B.C. De Cooman, Effect of micro-alloying elements on the stretch-flangeability of dual phase steel. Mater. Sci. Eng. A 536, 231–238 (2012)

X.J. Shen, X.H. Pei, S. Tang et al., Effects of coiling temperature on microstructure and mechanical properties of hot-rolled ferrite/bainite dual phase steel. J. Northeast. Univ. (Nat. Sci.) 35(8), 1120–1123 (2014) (in chinese)

W.W. Wang, H. Ding, Z.Y. Tang et al., Stretch-flangeability of ferrite–bainite steel. J. Iron Steel Res. 21(6), 48–52 (2009) (in chinese)

X. Fang, Z. Fan, B. Ralph et al., The relationships between tensile properties and hole expansion property of C-Mn steels. J. Mater. Sci. 38(18), 3877–3882 (2003)

A. Kaijalainen, V. Kesti, R. Vierelä et al., The effect of microstructure on the sheared edge quality and hole expansion ratio of hot-rolled 700 MPa steel. J. Phys. Conf. Ser. 896(1), 012103 (2017)

M. Cai, H. Ding, Y. Lee et al., Effects of Si on microstructural evolution and mechanical properties of hot-rolled ferrite and bainite dual-phase steels. ISIJ Int. 51(3), 476–481 (2011)

X. Fang, Z. Fan, B. Ralph et al., Effects of tempering temperature on tensile and hole expansion properties of a C-Mn steel. J. Mater. Process. Technol. 132(1–3), 215–218 (2003)

B.C. De Cooman, J.G. Speer, Fundamentals of Steel Product Physical Metallurgy (AIST, Association for Iron & Steel Technology, Warrendale, 2011)

Q. Yong, Second Phases in Structural Steels (Metallurgical Industry Press, Beijing, 2006)

G. Dini, A. Najafizadeh, R. Ueji et al., Tensile deformation behavior of high manganese austenitic steel: the role of grain size. Mater. Des. 31(7), 3395–3402 (2010)

G. Jha, S. Das, S. Sinha et al., Design and development of precipitate strengthened advanced high strength steel for automotive application. Mater. Sci. Eng. A 561, 394–402 (2013)

Acknowledgements

The authors appreciate the financial support by the National Natural Science Foundation of China (No. 51701015).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, B., Hu, X., Zhou, L. et al. Effect of Transformation Temperature on the Ferrite–Bainite Microstructures, Mechanical Properties and the Deformation Behavior in a Hot-Rolled Dual Phase Steel. Met. Mater. Int. 27, 319–327 (2021). https://doi.org/10.1007/s12540-019-00371-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00371-7