Abstract

Non-dairy matrices represent 63% of the vehicles used for probiotication. However, their benefits to human health may be hindered by food processing, storage, and movement through the gastrointestinal tract. The microencapsulation of probiotic bacteria is an alternative to increase their resistance to such challenges. This review outlines the current advances in the encapsulation of probiotics using emulsification methods. The review also addresses the influence of encapsulating agents on the yield, the final size of microcapsules, and the survival rate of probiotic microorganisms. The main drying methods for probiotic microparticles, the kind of foods used for probiotication, and the emerging methods of emulsification are discussed. Emulsion microencapsulation has proven to be a viable technique for the production of probiotic microcapsules, while freeze-drying is the most suitable drying technique due to the mild process conditions. Emulsification through membranes and microfluidic devices are potential encapsulation techniques owing to their ability to control particle size and to work under mild conditions. The emulsion microencapsulation is thus a potential technique for ensuring the safe delivery of next-generation probiotics applied to non-dairy products.

Graphical Abstract

Similar content being viewed by others

References

Hill C, Guarner F, Reid G et al (2014) The International Scientific Association for Probiotics and Prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nat Rev Gastroenterol Hepatol 11:506–514

Dias CO, dos Santos Opuski de Almeida J, Pinto SS et al (2018) Development and physico-chemical characterization of microencapsulated bifidobacteria in passion fruit juice: A functional non-dairy product for probiotic delivery. Food Biosci 24:26–36

Pimentel TC, da Costa WKA, Barão CE et al (2021) Vegan probiotic products: A modern tendency or the newest challenge in functional foods. Food Res Int 140:110033

Ashwar BA, Gani A, Gani A et al (2018) Production of RS4 from rice starch and its utilization as an encapsulating agent for targeted delivery of probiotics. Food Chem 239:287–294

de Liz GR, Verruck S, Canella MHM et al (2020) Stability of bifidobacteria entrapped in goat’s whey freeze concentrate and inulin as wall materials and powder properties. Food Res Int 127:108752

Prestes AA, Verruck S, Vargas MO et al (2021) Influence of guabiroba pulp (campomanesia xanthocarpa o. berg) added to fermented milk on probiotic survival under in vitro simulated gastrointestinal conditions. Food Res Int 141:110135

Cassani L, Gomez-Zavaglia A, Simal-Gandara J (2020) Technological strategies ensuring the safe arrival of beneficial microorganisms to the gut: From food processing and storage to their passage through the gastrointestinal tract. Food Res Int 129:108852

Rodrigues FJ, Cedran MF, Bicas JL, Sato HH (2020) Encapsulated probiotic cells: Relevant techniques, natural sources as encapsulating materials and food applications – A narrative review. Food Res Int 137:109682

Ghibaudo F, Gerbino E, Campo Dall’ Orto V, Gómez-Zavaglia A (2017) Pectin-iron capsules: Novel system to stabilise and deliver lactic acid bacteria. J Funct Foods 39:299–305

Oberoi K, Tolun A, Sharma K, Sharma S (2019) Microencapsulation: An overview for the survival of probiotic bacteria. J Microbiol Biotechnol Food Sci 9:280–287

Martín MJ, Lara-Villoslada F, Ruiz MA, Morales ME (2015) Microencapsulation of bacteria: A review of different technologies and their impact on the probiotic effects. Innov Food Sci Emerg Technol 27:15–25

Ðordevic´V, Balanč B, Belščak-Cvitanovic´A et al (2015) Trends in Encapsulation Technologies for Delivery of Food Bioactive Compounds. Food Eng Rev 7:452–490

Dehkordi SS, Alemzadeh I, Vaziri AS, Vossoughi A (2020) Optimization of Alginate-Whey Protein Isolate Microcapsules for Survivability and Release Behavior of Probiotic Bacteria. Appl Biochem Biotechnol 190:182–196

Beldarrain-Iznaga T, Villalobos-Carvajal R, Leiva-Vega J, Sevillano Armesto E (2020) Influence of multilayer microencapsulation on the viability of Lactobacillus casei using a combined double emulsion and ionic gelation approach. Food Bioprod Process 124:57–71

Ma L, Shang Y, Zhu Y et al (2020) Study on microencapsulation of Lactobacillus plantarum LIP-1 by emulsification method. J Food Process Eng 43:e13437

de Paula DA, Martins EMF, de Almeida Costa N et al (2019) Use of gelatin and gum arabic for microencapsulation of probiotic cells from Lactobacillus plantarum by a dual process combining double emulsification followed by complex coacervation. Int J Biol Macromol 133:722–731

Eratte D, Dowling K, Barrow CJ, Adhikari B (2018) Recent advances in the microencapsulation of omega-3 oil and probiotic bacteria through complex coacervation: A review. Trends Food Sci Technol 71:121–131

Anselmo AC, McHugh KJ, Webster J et al (2016) Layer-by-Layer Encapsulation of Probiotics for Delivery to the Microbiome. Adv Mater 28:9486–9490

Ghorani B, Tucker N (2015) Fundamentals of electrospinning as a novel delivery vehicle for bioactive compounds in food nanotechnology. Food Hydrocoll 51:227–240

Wang L, Song M, Zhao Z et al (2020) Lactobacillus acidophilus loaded pickering double emulsion with enhanced viability and colon-adhesion efficiency. LWT - Food Sci Technol 121:108928

Heidebach T, Först P, Kulozik U (2012) Microencapsulation of Probiotic Cells for Food Applications. Crit Rev Food Sci Nutr 52:291–311

Krasaekoopt W, Bhandari B, Deeth H (2003) Evaluation of encapsulation techniques of probiotics for yoghurt. Int Dairy J 13:3–13

Lu Y, Mao L, Hou Z et al (2019) Development of Emulsion Gels for the Delivery of Functional Food Ingredients: from Structure to Functionality. Food Eng Rev 11:245–258

Cook MT, Tzortzis G, Charalampopoulos D, Khutoryanskiy VV (2012) Microencapsulation of probiotics for gastrointestinal delivery. J Control Release 162:56–67

Rokka S, Rantamäki P (2010) Protecting probiotic bacteria by microencapsulation: Challenges for industrial applications. Eur Food Res Technol 231:1–12

Rosas-Flores W, Ramos-Ramírez EG, Salazar-Montoya JA (2013) Microencapsulation of Lactobacillus helveticus and Lactobacillus delbrueckii using alginate and gellan gum. Carbohydr Polym 98:1011–1017

Eshrati M, Amadei F, Van De Wiele T et al (2018) Biopolymer-Based Minimal Formulations Boost Viability and Metabolic Functionality of Probiotics Lactobacillus rhamnosus GG through Gastrointestinal Passage. Langmuir 34:11167–11175

Dong LM, Luan NT, Thuy DTK (2020) The viability of encapsulated Lactobacillus plantarum during cupcake baking process, storage, and simulated gastric digestion. J Microbiol Biotechnol Food Sci 9:1157–1161

Khosravi Zanjani MA, Ehsani MR, Tarzi BG, Sharifan A (2018) Promoting probiotics survival by microencapsualtion with hylon starch and genipin cross-linked coatings in simulated gastro-intestinal condition and heat treatment. Iran J Pharm Res 17:753–766

Qi W, Liang X, Yun T, Guo W (2019) Growth and survival of microencapsulated probiotics prepared by emulsion and internal gelation. J Food Sci Technol 56:1398–1404

Zheng H, Gao M, Ren Y et al (2017) An improved pH-responsive carrier based on EDTA-Ca-alginate for oral delivery of Lactobacillus rhamnosus ATCC 53103. Carbohydr Polym 155:329–335

Ji R, Wu J, Zhang J et al (2019) Extending viability of Bifidobacterium longum in chitosan-coated alginate microcapsules using emulsification and internal gelation encapsulation technology. Front Microbiol 10:1–10

Ramos PE, Cerqueira MA, Teixeira JA, Vicente AA (2018) Physiological protection of probiotic microcapsules by coatings. Crit Rev Food Sci Nutr 58:1864–1877

Chen H, Li X, Liu B, Meng X (2017) Microencapsulation of Lactobacillus bulgaricus and survival assays under simulated gastrointestinal conditions. J Funct Foods 29:248–255

Kamalian N, Mirhosseini H, Mustafa S et al (2014) Effect of alginate and chitosan on viability and release behavior of Bifidobacterium pseudocatenulatum G4 in simulated gastrointestinal fluid. Carbohydr Polym 111:700–706

Calinoiu LF, Ştefanescu BE, Pop ID et al (2019) Chitosan coating applications in probiotic microencapsulation. Coatings 9:1–21

Quintana G, Gerbino E (2018) Valorization of okara oil for the encapsulation of Lactobacillus plantarum. Food Res Int 106:81–89

Ayama H, Sumpavapol P, Chanthachum S (2014) Effect of encapsulation of selected probiotic cell on survival in simulated gastrointestinal tract condition. Songklanakarin J Sci Technol 36:291–299

Graça J, Godinho CA, Truninger M (2019) Reducing meat consumption and following plant-based diets: Current evidence and future directions to inform integrated transitions. Trends Food Sci Technol 91:380–390

Cavalheiro CP, Ruiz-Capillas C, Herrero AM et al (2020) Effect of encapsulated Lactobacillus plantarum as probiotic on dry-sausages during chilled storage. Int J Food Sci Technol 55:3613–3621

Cavalheiro CP, Ruiz-Capillas C, Herrero AM et al (2019) Effect of different strategies of Lactobacillus plantarum incorporation in chorizo sausages. J Sci Food Agric 99:6706–6712

Raddatz GC, de Souza da Fonseca B, Poletto G et al (2020) Influence of the prebiotics hi-maize, inulin and rice bran on the viability of pectin microparticles containing Lactobacillus acidophilus LA-5 obtained by internal gelation/emulsification. Powder Technol 362:409–415

Thangrongthong S, Puttarat N, Ladda B et al (2020) Microencapsulation of probiotic Lactobacillus brevis ST-69 producing GABA using alginate supplemented with nanocrystalline starch. Food Sci Biotechnol 29:1475–1482

Sengsaengthong S, Oonsivilai R (2019) Effect of microencapsulation of Lactobacillus sp. 21C2-10 isolated from cassava pulp on physicochemical, sensorial and microbiological characteristics of ice cream. Int Food Res J 26:585–594

Cremon C, Barbaro MR, Ventura M, Barbara G (2018) Pre- and probiotic overview. Curr Opin Pharmacol 43:87–92

George Kerry R, Patra JK, Gouda S et al (2018) Benefaction of probiotics for human health: A review. J Food Drug Anal 26:927–939

Kirmiz N, Galindo K, Cross KL et al (2020) Comparative Genomics Guides Elucidation of Vitamin B12 Biosynthesis in Novel Human-Associated Akkermansia Strains. Appl Environ Microbiol 86:e02117-e2119

van der Ark KCH, Nugroho ADW, Berton-Carabin C et al (2017) Encapsulation of the therapeutic microbe Akkermansia muciniphila in a double emulsion enhances survival in simulated gastric conditions. Food Res Int 102:372–379

Jiang T, Wu H, Yang X et al (2020) Lactobacillus mucosae strain promoted by a high-fiber diet in genetic obese child alleviates lipid metabolism and modifies gut microbiota in apoe-/- mice on a western diet. Microorganisms 8:1–17

Namai F, Murakami A, Ueda A et al (2020) Construction of Genetically Modified Lactococcus lactis Producing Anti-human-CTLA-4 Single-Chain Fragment Variable. Mol Biotechnol 62:572–579

Vernay T, Cannie I, Gaboriau F et al (2020) Bacteroides fragilis prevents Salmonella Heidelberg translocation in co-culture model mimicking intestinal epithelium. Benef Microbes 11:391–401

Deng H, Yang S, Zhang Y et al (2018) Bacteroides fragilis Prevents Clostridium difficile Infection in a Mouse Model by Restoring Gut Barrier and Microbiome Regulation. Front Microbiol 9:1–12

Hiippala K, Kainulainen V, Suutarinen M et al (2020) Isolation of anti-inflammatory and epithelium reinforcing Bacteroides and Parabacteroides spp. From a healthy fecal donor Nutrients 12:935

Del Pulgar EMG, Benítez-Páez A, Sanz Y (2020) Safety assessment of Bacteroides uniformis CECT 7771, a symbiont of the gut microbiota in infants. Nutrients 12:551

El Hage R, Hernandez-Sanabria E, Calatayud Arroyo M et al (2019) Propionate-producing consortium restores antibiotic-induced dysbiosis in a dynamic in vitro model of the human intestinal microbial ecosystem. Front Microbiol 10:1–17

Bhat B, Bajaj BK (2018) Hypocholesterolemic and bioactive potential of exopolysaccharide from a probiotic Enterococcus faecium K1 isolated from kalarei. Bioresour Technol 254:264–267

Kanmani P, Clua P, Vizoso-Pinto MG et al (2017) Respiratory commensal bacteria Corynebacterium pseudodiphtheriticum improves resistance of infant mice to respiratory syncytial virus and Streptococcus pneumoniae superinfection. Front Microbiol 8:1–14

Martín R, Miquel S, Benevides L et al (2017) Functional characterization of novel Faecalibacterium prausnitzii strains isolated from healthy volunteers: A step forward in the use of F. prausnitzii as a next-generation probiotic. Front Microbiol 8:1–13

Selma MV, Beltrán D, Luna MC et al (2017) Isolation of human intestinal bacteria capable of producing the bioactive metabolite isourolithin a from ellagic acid. Front Microbiol 8:1–8

Saarela MH (2019) Safety aspects of next generation probiotics. Curr Opin Food Sci 30:8–13

Barragán-Martínez LP, Totosaus A, de Lourdes P-C (2020) Probiotication of cooked sausages employing agroindustrial coproducts as prebiotic co-encapsulant in ionotropic alginate–pectin gels. Int J Food Sci Technol 55:1088–1096

Krithika B, Preetha R (2019) Formulation of protein based inulin incorporated synbiotic nanoemulsion for enhanced stability of probiotic. Mater Res Express 6:114003

Marcial-Coba MS, Cieplak T, Cahú TB et al (2018) Viability of microencapsulated: Akkermansia muciniphila and Lactobacillus plantarum during freeze-drying, storage and in vitro simulated upper gastrointestinal tract passage. Food Funct 9:5868–5879

Marcial-Coba MS, Saaby L, Knøchel S, Nielsen DS (2019) Dark chocolate as a stable carrier of microencapsulated Akkermansia muciniphila and Lactobacillus casei. FEMS Microbiol Lett 366:1–6

Kumherová M, Veselá K, Jokešová K et al (2020) Influence of co-encapsulation of Bifidobacterium animalis subsp. lactis BB-12 with inulin and ascorbic acid on its viability. Czech J Food Sci 38:57–62

Gharsallaoui A, Roudaut G, Chambin O et al (2007) Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res Int 40:1107–1121

de la Cruz P-C, Ortega D, García-Triana A et al (2020) A brief review of edible coating materials for the microencapsulation of probiotics. Coatings 10:1–36

Shafizadeh A, Golestan L, Ahmadi M et al (2020) Encapsulation of Lactobacillus casei in alginate microcapsules: improvement of the bacterial viability under simulated gastrointestinal conditions using flaxseed mucilage. J Food Meas Charact 14:1901–1908

Xiao Y, Han C, Yang H et al (2020) Layer (whey protein isolate) -by-layer (xanthan gum) microencapsulation enhances survivability of L. bulgaricus and L. paracasei under simulated gastrointestinal juice and thermal conditions. Int J Biol Macromol 148:238–247

Khosravi MA, Mohammad Z, Ehsani R et al (2018) Promoting Lactobacillus casei and Bifidobacterium adolescentis survival by microencapsulation with different starches and chitosan and poly L-lysine coatings in ice cream. J Food Process Preserv 42:e13318

Holkem AT, Raddatz GC, Nunes GL et al (2016) Development and characterization of alginate microcapsules containing Bifidobacterium BB-12 produced by emulsification/internal gelation followed by freeze drying. LWT - Food Sci Technol 71:302–308

Phoem AN, Chanthachum S, Voravuthikunchai SP (2015) Preparation of Eleutherine americana-alginate complex microcapsules and application in Bifidobacterium longum. Nutrients 7:831–848

Song H, Yu W, Liu X, Ma X (2014) Improved probiotic viability in stress environments with post-culture of alginate-chitosan microencapsulated low density cells. Carbohydr Polym 108:10–16

Papagianni M, Anastasiadou S (2009) Encapsulation of Pediococcus acidilactici cells in corn and olive oil microcapsules emulsified by peptides and stabilized with xanthan in oil-in-water emulsions: Studies on cell viability under gastro-intestinal simulating conditions. Enzyme Microb Technol 45:514–522

Sánchez MT, Ruiz MA, Lasserrot A et al (2017) An improved ionic gelation method to encapsulate Lactobacillus spp. bacteria: Protection, survival and stability study. Food Hydrocoll 69:67–75

Raddatz GC, Poletto G, de Deus C et al (2020) Use of prebiotic sources to increase probiotic viability in pectin microparticles obtained by emulsification/internal gelation followed by freeze-drying. Food Res Int 130:108902

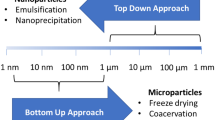

Campos E, Branquinho J, Carreira AS et al (2013) Designing polymeric microparticles for biomedical and industrial applications. Eur Polym J 49:2005–2021

Yao M, Xie J, Du H et al (2020) Progress in microencapsulation of probiotics: A review. Compr Rev Food Sci Food Saf 19:857–874

Mokhtari S, Jafari SM, Khomeiri M et al (2017) The cell wall compound of Saccharomyces cerevisiae as a novel wall material for encapsulation of probiotics. Food Res Int 96:19–26

Marcial-Coba MS, Knøchel S, Nielsen DS (2019) Low-moisture food matrices as probiotic carriers. FEMS Microbiol Lett 366:1–11

Holkem TA, Raddatz CG, Barin SJ et al (2017) Production of microcapsules containing Bifidobacterium BB-12 by emulsification / internal gelation. LWT - Food Sci Technol 76:216–221

Zhang F, Li XY, Park HJ, Zhao M (2013) Effect of microencapsulation methods on the survival of freeze-dried Bifidobacterium bifidum. J Microencapsul 30:511–518

Morelli S, Holdich RG, Dragosavac MM (2017) Microparticles for cell encapsulation and colonic delivery produced by membrane emulsification. J Memb Sci 524:377–388

Smilkov K, Petreska Ivanovska T, Petrushevska Tozi L et al (2014) Optimization of the formulation for preparing Lactobacillus casei loaded whey protein-Ca-alginate microparticles using full-factorial design. J Microencapsul 31:166–175

Bernucci BSP, Loures CMG, Sabino AP et al (2017) Effect of microencapsulation conditions on the viability and functionality of Bifidobacterium longum 51A. LWT - Food Sci Technol 80:341–347

Kwiecień I, Kwiecień M (2018) Application of Polysaccharide-Based Hydrogels as Probiotic Delivery Systems. Gels 4:47

Liu L, Li X, Zhu Y et al (2016) Effect of microencapsulation with Maillard reaction products of whey proteins and isomaltooligosaccharide on the survival of Lactobacillus rhamnosus. LWT - Food Sci Technol 73:37–43

Šipailienė A, Petraitytė S (2018) Encapsulation of Probiotics: Proper Selection of the Probiotic Strain and the Influence of Encapsulation Technology and Materials on the Viability of Encapsulated Microorganisms. Probiotics Antimicrob Proteins 10:1–10

Juárez-Trujillo N, Jiménez-Fernández M, Franco-Robles E et al (2021) Effect of three-stage encapsulation on survival of emulsified Bifidobacterium animalis subsp. Lactis during processing, storage and simulated gastrointestinal tests. LWT - Food Sci Technol 137:110468

Kataria A, Achi SC, Halami PM (2018) Effect of Encapsulation on Viability of Bifidobacterium longum CFR815j and Physiochemical Properties of Ice Cream. Indian J Microbiol 58:248–251

Oguntoye MA, Ezekiel OO, Oridupa OA (2021) Viability of Lactobacillus rhamnosus GG in provitamin A cassava hydrolysate during fermentation, storage, in vitro and in vivo gastrointestinal conditions. Food Biosci 40:100845

El Kadri H, Lalou S, Mantzouridou FT, Gkatzionis K (2018) Utilisation of water-in-oil-water (W1/O/W2) double emulsion in a set-type yogurt model for the delivery of probiotic Lactobacillus paracasei. Food Res Int 107:325–336

Gul O (2017) Microencapsulation of Lactobacillus casei Shirota by spray drying using different combinations of wall materials and application for probiotic dairy dessert. J Food Process Preserv 41:e13198

Horáčková S, Rokytová K, Bialasová K et al (2018) Fruit juices with probiotics – New type of functional foods. Czech J Food Sci 36:284–288

Martinez CJ, Kim JW, Ye C et al (2012) A Microfluidic Approach to Encapsulate Living Cells in Uniform Alginate Hydrogel Microparticles. Macromol Biosci 12:946–951

Picone CSF, Bueno AC, Michelon M, Cunha RL (2017) Development of a probiotic delivery system based on gelation of water-in-oil emulsions. LWT - Food Sci Technol 86:62–68

Broeckx G, Vandenheuvel D, Claes IJJ et al (2016) Drying techniques of probiotic bacteria as an important step towards the development of novel pharmabiotics. Int J Pharm 505:303–318

Heylen K, Hoefman S, Vekeman B et al (2012) Safeguarding bacterial resources promotes biotechnological innovation. Appl Microbiol Biotechnol 94:565–574

Dianawati D, Shah NP (2011) Survival, Acid and Bile Tolerance, and Surface Hydrophobicity of Microencapsulated B. animalis ssp. lactis BB-12 during Storage at Room Temperature. J Food Sci 76:M92–M99

Sosnik A, Seremeta KP (2015) Advantages and challenges of the spray-drying technology for the production of pure drug particles and drug-loaded polymeric carriers. Adv Colloid Interface Sci 223:40–54

Huang S, Vignolles ML, Chen XD et al (2017) Spray drying of probiotics and other food-grade bacteria: A review. Trends Food Sci Technol 63:1–17

Perdana J, Bereschenko L, Fox MB et al (2013) Dehydration and thermal inactivation of Lactobacillus plantarum WCFS1: Comparing single droplet drying to spray and freeze drying. Food Res Int 54:1351–1359

Perdana J, Fox MB, Siwei C et al (2014) Interactions between formulation and spray drying conditions related to survival of Lactobacillus plantarum WCFS1. Food Res Int 56:9–17

Stummer S, Toegel S, Rabenreither MC et al (2012) Fluidized-bed drying as a feasible method for dehydration of Enterococcus faecium M74. J Food Eng 111:156–165

Bilenler T, Karabulut I, Candogan K (2017) Effects of encapsulated starter cultures on microbial and physicochemical properties of traditionally produced and heat treated sausages (sucuks). LWT - Food Sci Technol 75:425–433

Muthukumarasamy P, Holley RA (2006) Microbiological and sensory quality of dry fermented sausages containing alginate-microencapsulated Lactobacillus reuteri. Int J Food Microbiol 111:164–169

Dong LM, Luan NT, Thuy DTK (2020) Enhancing the viability rate of probiotic by co-encapsulating with prebiotic in alginate microcapsules supplemented to cupcake production. Microbiol Biotechnol Lett 48:113–120

Seyedain-Ardabili M, Sharifan A, Tarzi BG (2016) The production of synbiotic bread by microencapsulation. Food Technol Biotechnol 54:52–59

Amine KM, Champagne CP, Raymond Y et al (2014) Survival of microencapsulated Bifidobacterium longum in Cheddar cheese during production and storage. Food Control 37:193–199

Rodríguez-Huezo ME, Estrada-Fernández AG, García-Almendárez BE et al (2014) Viability of Lactobacillus plantarum entrapped in double emulsion during Oaxaca cheese manufacture, melting and simulated intestinal conditions. LWT - Food Sci Technol 59:768–773

Ozer B, Uzun YS, Kirmaci HA (2008) Effect of microencapsulation on viability of Lactobacillus acidophilus LA-5 and Bifidobacterium bifidum BB-12 during kasar cheese ripening. Int J Dairy Technol 61:237–244

Özer B, Kirmaci HA, Şenel E et al (2009) Improving the viability of Bifidobacterium bifidum BB-12 and Lactobacillus acidophilus LA-5 in white-brined cheese by microencapsulation. Int Dairy J 19:22–29

Huerta-Vera K, Flores-Andrade E, Pérez-Sato JA et al (2017) Enrichment of Banana with Lactobacillus rhamnosus Using Double Emulsion and Osmotic Dehydration. Food Bioprocess Technol 10:1053–1062

Flores-Andrade E, Pascual-Pineda LA, Alarcón-Elvira FG et al (2017) Effect of vacuum on the impregnation of Lactobacillus rhamnosus microcapsules in apple slices using double emulsion. J Food Eng 202:18–24

De Prisco A, Mauriello G (2016) Probiotication of foods: A focus on microencapsulation tool. Trends Food Sci Technol 48:27–39

Terpou A, Papadaki A, Lappa IK et al (2019) Probiotics in Food Systems: Significance and Emerging Strategies Towards Improved Viability and Delivery of Enhanced Beneficial Value. Nutrients 11:32

Khan MI, Arshad MS, Anjum FM et al (2011) Meat as a functional food with special reference to probiotic sausages. Food Res Int 44:3125–3133

Rubio R, Jofré A, Aymerich T et al (2014) Nutritionally enhanced fermented sausages as a vehicle for potential probiotic Lactobacilli delivery. Meat Sci 96:937–942

Song SH, Cho YH, Park J (2003) Microencapsulation of Lactobacillus casei YIT 9018 using a microporous glass membrane emulsification system. J Food Sci 68:195–200

Joscelyne SM, Trägårdh G (2000) Membrane emulsification - A literature review. J Memb Sci 169:107–117

Vinner GK, Richards K, Leppanen M et al (2019) Microencapsulation of enteric bacteriophages in a pH-Responsive solid oral dosage formulation using a scalable membrane emulsification process. Pharmaceutics 11:11090475

Charcosset C (2009) Preparation of emulsions and particles by membrane emulsification for the food processing industry. J Food Eng 92:241–249

Spyropoulos F, Lloyd DM, Hancocks RD, Pawlik AK (2014) Advances in membrane emulsification. Part B: Recent developments in modelling and scale-up approaches. J Sci Food Agric 94:628–638

Vladisavljević GT (2019) Preparation of microemulsions and nanoemulsions by membrane emulsification. Colloids Surfaces A Physicochem Eng Asp 579:123709

Piacentini E, Drioli E, Giorno L (2014) Membrane emulsification technology: Twenty-five years of inventions and research through patent survey. J Memb Sci 468:410–422

Spyropoulos F, Lloyd DM, Hancocks RD, Pawlik AK (2014) Advances in membrane emulsification. Part A: Recent developments in processing aspects and microstructural design approaches. J Sci Food Agric 94:613–627

Consolli L, Hubinger MD, Dragosavac MM (2020) Encapsulation of resveratrol using Maillard conjugates and membrane emulsification. Food Res Int 137:109359

Vladisavljević GT, Williams RA (2005) Recent developments in manufacturing emulsions and particulate products using membranes. Adv Colloid Interface Sci 113:1–20

Gijsbertsen-Abrahamse AJ, Van Der Padt A, Boom RM (2004) Status of cross-flow membrane emulsification and outlook for industrial application. J Memb Sci 230:149–159

Charcosset C, Limayem I, Fessi H (2004) Review The membrane emulsification process-a review. J Chem Technol Biotechnol 79:209–218

Williams RA (1998) Controlled Production of Emulsions Using a Crossflow Membrane: Part II: Industrial Scale Manufacture. Chem Eng Res Des 76:902–910

Suárez MA, Gutiérrez G, Coca J, Pazos C (2013) Stirred tank membrane emulsification using flat metallic membranes: A dimensional analysis. Chem Eng Process Process Intensif 69:31–43

McClements DJ, Jafari SM (2018) Improving emulsion formation, stability and performance using mixed emulsifiers: A review. Adv Colloid Interface Sci 251:55–79

Dikit P, H-Kittikun A, Maneerat S (2015) Survival of encapsulated potentially probiotic Lactobacillus plantarum D6SM3 with bioemulsifier derived from spent yeast in simulated gastrointestinal conditions. Songklanakarin J Sci Technol 37:425–432

Schröder V, Behrend O, Schubert H (1998) Effect of Dynamic Interfacial Tension on the Emulsification Process Using Microporous, Ceramic Membranes. J Colloid Interface Sci 202:334–340

Kobayashi I, Yasuno M, Iwamoto S et al (2002) Microscopic observation of emulsion droplet formation from a polycarbonate membrane. Colloids Surfaces A Physicochem Eng Asp 207:185–196

Dragosavac MM, Sovilj MN, Kosvintsev SR et al (2008) Controlled production of oil-in-water emulsions containing unrefined pumpkin seed oil using stirred cell membrane emulsification. J Memb Sci 322:178–188

Piacentini E, Giorno L, Dragosavac MM et al (2013) Microencapsulation of oil droplets using cold water fish gelatine/gum arabic complex coacervation by membrane emulsification. Food Res Int 53:362–372

Kosvintsev SR, Gasparini G, Holdich RG et al (2005) Liquid-Liquid Membrane Dispersion in a Stirred Cell with and without Controlled Shear. Ind Eng Chem Res 44:9323–9330

Ekanem EE, Zhang Z, Vladisavljević GT (2017) Facile microfluidic production of composite polymer core-shell microcapsules and crescent-shaped microparticles. J Colloid Interface Sci 498:387–394

Vladisavljević GT (2016) Recent advances in the production of controllable multiple emulsions using microfabricated devices. Particuology 24:1–17

Vladisavljević GT, Al Nuumani R, Nabavi SA (2017) Microfluidic Production of Multiple Emulsions. Micromachines 8:75

Ji Y, Bellettre J, Montillet A, Massoli P (2021) Effect of cross-slot configuration in microfluidics on o/w emulsification at high throughput.Microfluid Nanofluid 25:85

Nabavi SA, Vladisavljević GT, Bandulasena MV et al (2017) Prediction and control of drop formation modes in microfluidic generation of double emulsions by single-step emulsification. J Colloid Interface Sci 505:315–324

Abate AR, Thiele J, Weitz DA (2011) One-step formation of multiple emulsions in microfluidics. Lab Chip 11:253–258

Abate AR, Thiele J, Weinhart M, Weitz DA (2010) Patterning microfluidic device wettability using flow confinement. Lab Chip 10:1774–1776

Garstecki P, Fuerstman MJ, Stone HA, Whitesides GM (2006) Formation of droplets and bubbles in a microfluidic T-junction-scaling and mechanism of break-up. Lab Chip 6:347–446

Adak A, Maity C, Ghosh K et al (2013) Dynamics of predominant microbiota in the human gastrointestinal tract and change in luminal enzymes and immunoglobulin profile during high-altitude adaptation. Folia Microbiol (Praha) 58:523–528

Rodklongtan A, La-Ongkham O, Nitisinprasert S, Chitprasert P (2014) Enhancement of Lactobacillus reuteri KUB-AC5 survival in broiler gastrointestinal tract by microencapsulation with alginate-chitosan semi-interpenetrating polymer networks. J Appl Microbiol 117:227–238

Acknowledgements

The authors are grateful to CNPq (National Council for Scientific and Technological Development, Brazil) for the financial support (420275/2018-5, 307576/2018-3), and to CAPES (Coordination of Improvement of Higher Education Personnel) for the scholarship (PROEX).

Author information

Authors and Affiliations

Contributions

Callebe Camelo-Silva: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Software, Writing-original draft. Silvani Verruck: Conceptualization, Data curation, Formal analysis, Methodology, Writing-review & editing. Alan Ambrosi: Conceptualization, Data curation, Formal analysis, Methodology, Writing-review & editing. Marco Di Luccio: Conceptualization, Formal analysis, Methodology, Funding acquisition, Project administration, Resources, Supervision, Writing-review & editing.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Camelo-Silva, C., Verruck, S., Ambrosi, A. et al. Innovation and Trends in Probiotic Microencapsulation by Emulsification Techniques. Food Eng Rev 14, 462–490 (2022). https://doi.org/10.1007/s12393-022-09315-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-022-09315-1