Abstract

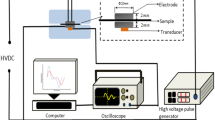

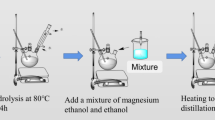

Small physical voids will reduce the dielectric strength of epoxy resin and seriously threaten electronic devices’ reliability. Self-healing is a practical approach to maintain the electrical and mechanical characteristics of epoxy resin. In this research, epoxy resins incorporated with various concentrations of microcapsules were prepared. The microcapsules were treated using a silane coupling agent (KH550) to enhance dispersion. Moreover, the self-healing performance of the epoxy resin incorporated with microcapsules was analysed by FTIR, SEM, AC breakdown strength, tensile strength, dielectric properties and thermal-stimulated current (TSC). The SEM results indicate that the microcapsules/epoxy resin composite has improved self-healing performance compared to pure epoxy resin. DC volume and surface resistivity of epoxy resins altered obviously after incorporation of microcapsules. Furthermore, the AC breakdown strength of epoxy resin doped with 5 wt% microcapsules was found relatively higher than that of pure epoxy resin. The tensile strength of the epoxy with 5 wt% microcapsules increased initially and then decreased gradually with increasing microcapsule content up to 15 wt%. The dielectric constant and dielectric loss of the epoxy resin/microcapsules composites are slightly higher than that of the pure epoxy resin when the content of the microcapsule is 5%, however, with the increase in microcapsule concentration, the dielectric constant and dielectric loss increase due to the weak interaction zone between microcapsules and epoxy resin. The distribution of trap energy and trap density obtained by TSC measurements revealed that 5 wt% have deeper traps and the highest trap energy levels.

Similar content being viewed by others

References

Khan M Z, Wang F, He Li, Shen Z, Huang Z and Mehmood M A 2020 Dielectr. Electr. Insul. 27 410

Khan M Z, Waleed A, Khan A, Hassan M A S, Paracha Z J and Farooq U 2020 Electro. Mater. Sci. 49, Article ID 3400

Wang F, Zhang T, Li J, Khan M Z, Huang Z, He Li et al 2019 IEEE Trans. Dielectr. Electr. Insul. 26 731

Wang F, He L, Khan M Z, Wang F, Zhang T, Zhao Q et al 2019 Appl. Sci. 9 Article ID 3879

Wang Y, Liu Y, Wang S and Xu H 2018 Trans. China Electrotech. Soc. 33 250

Wang Y, Liu Y and Xiao K 2018 J. Electr. Eng. Technol. 13 892

Chen L, Tsao T and Lin Y 2005 IEEE Trans. Power Deliv. 20 2501

Huang M, Zhou K, Yang D and Yang M 2016 Trans. China Electrotech. Soc. 31 176

Brown E N, White S R and Sottos N R 2005 Compos. Sci. Technol. 65 2474

Yang M, Zhou K, Wu K, Tao W and Yang D 2015 Trans. China Electrotech. Soc. 30 481

Khan M Z, Zaib A, Khan A, Hassan M A S, Javed Paracha Z and Farooq U 2021 J. Mater. Sci.: Mater. Electron. 32 2765

White S R, Sottos N R, Geubelle P H, Moore J S, Kessler M R and Sriram S R 2001 Nature 409 794

Bekas D G, Tsirka K, Baltzis D and Paipetis A S 2016 Composites Part. B: Eng. 87 92

Li W, Dong B, Yang Z, Xu J, Chen Q, Li H et al 2018 Adv. Mater. 30 Article ID 1705679

Murphy E B and Wudl F 2010 Prog. Polym. Sci. 35 223

An S, Lee M W, Yarin A L and Yoon S S 2018 Chem. Eng. J. 344 206

Li W, Wu G, Tan J, Yu X, Sun G and You B 2019 Macromol. Mater. Eng. 304, Article ID 1800765

Kessler M R, Sottos N R and White S R 2003 Composites Part A: Appl. Sci. Manuf. 34 743

Wang Y, Li Y, Zhang Z and Zhang Y 2019 Appl. Sci. 9, Article ID 3039

Shen WW, Mu H B, Zhang G J, Deng J B and Tu D M 2013 J. Appl. Phys. 113, Article ID 083706

Zhang X, Ji H and Qiao Z 2014 Mater. Lett. 137 9

Liu C, Zheng X and Bie C 2016 Mater. Trans. China Electrotech. Soc. 31 24

Wu Z, Wang C, Zhang M, Pei X and Jiang P 2018 Trans. China Electrotech. Soc. 33 241

Zhang H, Wang P and Yang J 2014 Compos. Sci. Technol. 94 23

Yuan Y C, Rong M Z, Zhang M Q, Chen J, Yang G C and Li X M 2008 Macromolecules 41 5197

Li Q, Kim N H, Hui D and Lee J H 2013 Composites B 55 79

Chen R 1976 J. Mater. Sci. 11 1521

Lewis T J 2004 IEEE Trans. Dielectr. Electr. Insul. 11 739

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Khan, M.Z., Farooq, U., Imtiaz, M.A. et al. Effect of microcapsules doping on dielectric performance of self-healing epoxy resin composites. Bull Mater Sci 44, 262 (2021). https://doi.org/10.1007/s12034-021-02536-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-021-02536-w