Abstract

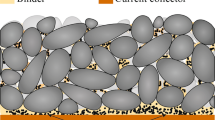

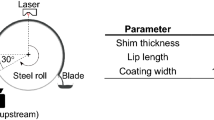

The slot-die coating is the most commonly used manufacturing method for producing lithium-ion battery electrodes. However, how to achieve high surface consistency for electrodes still confronts one challenge. In this research, the slot coating processes with different die lip configurations were carefully investigated using numerical and experimental methods. The motion pattern, internal flow structure of the coating bead, and coating uniformity were explored during the coating process of lithium battery cathode slurry. The low-flow limit at different coating gaps was also determined by combining the viscous capillary model and numerical methods, which was in good agreement with experimental results. The results showed that a smaller coating gap controlling the upstream meniscus between the upstream die lip and slot exit was favorable to the coating uniformity. For the same thickness films, a larger coating gap was apt to increase formation of edge defects. However, the coating speed had little effect on the edge height. The evolution of flow structure for the coating bead (parabolic–sharp angle–diagonal) under different processes was investigated by tracking the particle trajectories during the coating process. It can provide theoretical guidance for the fabrication of high-quality electrodes.

Similar content being viewed by others

References

Creel, EB, Tjiptowidjojo, K, Lee, JA, et al. “Slot-Die-Coating Operability Windows for Polymer Electrolyte Membrane Fuel Cell Cathode Catalyst Layers.” J. Colloid Interface Sci., 610 474–485 (2022)

Ding, X, Liu, J, Harris, TAL, “A Review of the Operating Limits in Slot Die Coating Processes.” AICHE J., 62 (7) 2508–2524 (2016)

Mohanty, D, Hockaday, E, Li, J, et al. “Effect of Electrode Manufacturing Defects on Electrochemical Performance of Lithium-Ion Batteries: Cognizance of the Battery Failure Sources.” J. Power Sources, 312 70–79 (2016)

Ruschak, KJ, “Limiting Flow in a Pre-metered Coating Device.” Chem. Eng. Sci., 31 (11) 1057–1060 (1976)

Landau, L, Levich, B, “Dragging of a Liquid by a Moving Plate.” Acta Physicochim. URSS, 17 42–54 (1942)

Higgins, BG, Scriven, LE, “Capillary Pressure and Viscous Pressure Drop Set Bounds on Coating Bead Operability.” Chem. Eng. Sci., 35 (3) 673–682 (1980)

Koh, HJ, Kwon, I, Jung, HW, et al. “Operability Window of Slot Coating Using Viscocapillary Model for Carreau-Type Coating Liquids.” Korea Aust. Rheol. J., 24 (2) 137–141 (2012)

Lee, SH, Koh, HJ, Ryu, BK, et al. “Operability Coating Windows and Frequency Response in Slot Coating Flows from a Viscocapillary Model.” Chem. Eng. Sci., 66 (21) 4953–4959 (2011)

Tsuda, T, “Coating Flows of Power-Law Non-Newtonian Fluids in Slot Coating.” Nihon Reoroji Gakkaishi, 38 (45) 223–230 (2011)

Jang, I, Song, S, “A Model for Prediction of Minimum Coating Thickness in High Speed Slot Coating.” Int. J. Heat Fluid Flow, 40 180–185 (2013)

Yoon, J, Kim, D, Lee, SH, et al. “Simplified Model for Operability Window of Slot Coating Without Vacuum.” Chem. Eng. Sci., 259 117766 (2022)

Carvalho, MS, Kheshgi, HS, “Low-Flow Limit in Slot Coating: Theory and Experiments.” AICHE J., 46 (10) 1907–1917 (2000)

Chang, YR, Chang, HM, Lin, CF, et al. “Three Minimum Wet Thickness Regions of Slot Die Coating.” J. Colloid Interface Sci., 308 (1) 222–230 (2007)

Kwak, H, Nam, J, “Effect of Slot-Die Configurations on Coating Gap Dependence of Maximum and Minimum Wet Thicknesses.” AICHE J., 68 e17745 (2022)

Malakhov, R, Tjiptowidjojo, K, Schunk, PR, “Mechanics of the Low-Flow Limit in Slot-Die Coating with No Vacuum.” AICHE J., 65 (6) e16593 (2019)

Lee, SH, Kim, SJ, Nam, J, et al. “Effect of Sloped Die Lip Geometry on the Operability Window in Slot Coating Flows Using Viscocapillary and Two-dimensional Models.” J. Coat. Technol. Res., 11 (1) 47–55 (2014)

Ahn, WG, Lee, SH, Nam, J, et al. “Effect of Upstream Meniscus Shape on Dynamic Wetting and Operating Limits of Newtonian Coating Liquids in Slot Coating Bead Flows.” J. Coat. Technol. Res., 15 (5) 1067–1076 (2018)

Tan, P, Diao, S, Huang, T, et al. “Mechanism and Control of the Trailing Edge in Intermittent Slot Die Coating.” Ind. Eng. Chem. Res., 59 (35) 15758–15767 (2020)

Bhamidipati, KL, “Detection and Elimination of Defects During Manufacture of High-temperature Polymer Electrolyte Membranes.” Dissertation, Georgia Institute of Technology (2011)

Bhamidipati, KL, Harris, TAL, “Numerical Simulation of a High Temperature Polymer Electrolyte Membrane Fabrication Process.” J. Fuel Cell Sci. Technol., 7 (6) 061005 (2010)

Huang, T, Tan, P, Zhong, Z, et al. “Numerical and Experimental Investigation on the Defect Formation in Lithium-Ion-Battery Electrode-Slot Coating.” Chem. Eng. Sci., 258 117744 (2022)

Kim, S, Lee, J, Lee, C, “Computational Fluid Dynamics Model for Thickness and Uniformity Prediction of Coating Layer in Slot-Die Process.” Int. J. Adv. Manuf. Technol., 104 (5) 2991–2997 (2019)

Jung, H, Nam, J, “Numerical Analysis of Pulsatile Flows in a Slot-Die Manifold.” J. Coat. Technol. Res., 16 (4) 1141–1151 (2019)

Schmitt, M, Baunach, M, Wengeler, L, et al. “Slot-die Processing of Lithium-Ion Battery Electrodes-Coating Window Characterization.” Chem. Eng. Process., 68 32–37 (2013)

Kwade, A, Haselrieder, W, Leithoff, R, et al. “Current Status and Challenges for Automotive Battery Production Technologies.” Nat. Energy, 3 (4) 290–300 (2018)

Pan, W, Chen, Z, Chen, X, et al. “Slot Die Coating Window for a Uniform Fuel Cell Ink Dispersion.” AICHE J., 68 e17719 (2022)

Siqueira, IR, Carvalho, MS, “A Computational Study of the Effect of Particle Migration on the Low-Flow Limit in Slot Coating of Particle Suspensions.” J. Coat. Technol. Res., 16 (6) 1619–1628 (2019)

de Araujo, SB, Carvalho, MS, “Sedimentation and Marangoni Stress in Slot Coating Flow of Particle Suspension.” J. Non Newton. Fluid Mech., 247 53–61 (2017)

Rebouças, RB, Siqueira, IR, Carvalho, MS, “Slot Coating Flow of Particle Suspensions: Particle Migration in Shear Sensitive Liquids.” J. Nonnewton. Fluid Mech., 258 22–31 (2018)

Hirt, CW, Nichols, BD, “Volume of Fluid (VOF) Method for the Dynamics of Free Boundaries.” J. Comput. Phys., 39 (1) 201–225 (1981)

Schmitt, M, Scharfe, P, Schabel, W, “Slot Die Coating of Lithium-Ion Battery Electrodes: Investigations on Edge Effect Issues for Stripe and Pattern Coatings.” J. Coat. Technol. Res., 11 (1) 57–63 (2014)

Blake, TD, Dobson, RA, Ruschak, KJ, “Wetting at High Capillary Numbers.” J. Colloid Interface Sci., 279 (1) 198–205 (2004)

Spiegel, S, Heckmann, T, Altvater, A, et al. “Investigation of Edge Formation During the Coating Process of Li-Ion Battery Electrodes.” J. Coat. Technol. Res., 19 (1) 121–130 (2022)

Higgins, BG, The Physics of the Viscocapillary Coating Bead. Convertech (2001)

Kwak, H, Nam, J, “Simple Criterion for Vortex Formation in the Channel Flow of Power-Law Fluids.” J. Nonnewton. Fluid Mech., 284 104372 (2020)

Acknowledgments

The work was supported by grants from the Research Project Supported by Shanxi Scholarship Council of China (Grant No: 2021-137) and Fundamental Research Program of Shanxi Province (Grant No: 202103021224273).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gong, X., Han, J., Yan, F. et al. Numerical and experimental investigation on formation of the film for different die lip configurations in lithium-ion battery electrode slot-die coating. J Coat Technol Res 21, 481–492 (2024). https://doi.org/10.1007/s11998-023-00874-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00874-4