Abstract

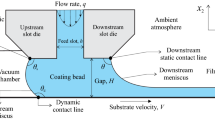

The operability windows and coating bead dynamics for the dual-layer slot coating process with non-Newtonian coating liquids were investigated using the viscocapillary model, a two-dimensional (2D) CFD simulation, and experiments. The simplified viscocapillary model derived from the 2D equation of motion with the shear-thinning Carreau liquids bounds the uniform coating regime without defects such as leaking, bead break-up, and mid-gap invasion in dual-layer coating systems. The coating bead flows from experiments and finite-volume-based 2D simulations with the volume-of-fluid scheme demonstrate the performance of the viscocapillary model in reliably tracking the upstream meniscus position of the bottom layer in the coating bead region. The onset of leaking, bead break-up, and mid-gap invasion defects is strongly affected by the rheological properties of Carreau-type coating liquids and the flow ratio between the top and bottom layers. In particular, the relative thickness of the shear-thinning bottom layer at the onset of mid-gap invasion is smaller than the well-known 1/3 value in the Newtonian case, depending on the degree of shear thinning.

Similar content being viewed by others

References

Schmitt, M, Raupp, S, Wagner, D, Scharfer, P, Schabel, W, “Analytical Determination of Process Windows for Bilayer Slot Die Coating.” J. Coat. Technol. Res., 12 877–887 (2015)

Diehm, R, Weinmann, H, Kumberg, J, Schmitt, M, Fleischer, J, Scharfer, P, Schabel, W, “Edge Formation in High-speed Intermittent Slot-Die Coating of Disruptively Stacked Thick Battery Electrodes.” Energy Technol., 8 1–8 (2020)

Parsekian, AW, Harris, TAL, “Scalable, Alternating Narrow Stripes of Polyvinyl Alcohol Support and Unmodified PEDOT:PSS with Maintained Conductivity Using a Single-Step Slot Die Coating Approach.” ACS Appl. Mater. Interfaces, 12 3736–3745 (2020)

Kim, D-J, Shin, H-I, Ko, E-H, Kim, K-H, Kim, T-W, Kim, H-K, “Roll-to-roll Slot-die Coating of 400 mm Wide, Flexible, Transparent Ag Nanowire Films for Flexible Touch Screen Panels.” Sci. Rep., 6 34322 (2016)

Sartor, L, “Slot Coating: Fluid Mechanics and Die Design.” Ph.D. Thesis, University of Minnesota, Minneapolis, United States, 1990

Gutoff, EB, Cohen, ED, Coating and Drying Defects: Troubleshooting Operating Problems, 2nd edn. John Wiley & Sons, Hoboken, NJ (2006)

Kistler, SF, Schweizer, PM, Liquid Film Coating: Scientific Principles and Their Technological Implications. Springer, Berlin (1997)

Ding, X, Liu, J, Harris, TAL, “A Review of the Operating Limits in Slot Die Coating Processes.” AIChE J., 62 2508–2524 (2016)

Higgins, BG, Scriven, LE, “Capillary Pressure and Viscous Pressure Drop Set Bounds on Coating Bead Operability.” Chem. Eng. Sci., 35 673–682 (1979)

Lee, YW, Ahn, W-G, Nam, J, Jung, HW, Hyun, JC, “Operability Windows in Viscoelastic Slot Coating Flows Using a Simplified Viscoelastic-capillary Model.” Rheol. Acta, 56 707–717 (2017)

Ahn, W-G, Lee, SH, Nam, J, Kim, SJ, Lee, KY, Jung, HW, “Effect of Upstream Meniscus Shape on Dynamic Wetting and Operating Limits of Newtonian Coating Liquids in Slot Coating Bead Flows.” J. Coat. Technol. Res., 15 1067–1076 (2018)

Cohen, D, “Two-layer Slot Coating: Flow Visualization and Modeling.” MS Thesis, University of Minnesota, Minneapolis, United States (1993)

Taylor, SD, Hrymak, AN, “Visualization and Flow Simulation of a Two-layer Slot Coater.” Chem. Eng. Sci., 54 909–918 (1999)

Nam, J, Carvalho, MS, “Mid-gap Invasion in Two-layer Slot Coating.” J. Fluid Mech., 631 397–417 (2009)

Nam, J, Carvalho, MS, “Linear Stability Analysis of Two-layer Rectilinear Flow in Slot Coating.” AIChE J., 56 2503–2512 (2010)

Nam, J, Carvalho, MS, “Two-layer Tensioned-web-over-slot Die Coating: Effect of Operating Conditions on Coating Window.” Chem. Eng. Sci., 65 4065–4079 (2010)

Ji, HS, Ahn, W-G, Kwon, I, Nam, J, Jung, HW, “Operability Coating Window of Dual-layer Slot Coating Process Using Viscocapillary Model.” Chem. Eng. Sci., 143 122–129 (2016)

Musson, LC, “Two-layer Slot Coating.” Ph.D. Thesis, University of Minnesota, Minneapolis, United States (2001)

Tsuda, T, “Coating Flows of Power-law Non-Newtonian Fluids in Slot Coating.” Nihon Reoroji Gakkaishi, 38 223–230 (2010)

Kwak, H, Nam, J, “Simple Criterion for Vortex Formation in the Channel Flow of Power-law Fluids.” J. Non-Newton. Fluid Mech., 284 104372 (2020)

Weinstein, SJ, Ruschak, KJ, “Coating Flows.” Annu. Rev. Fluid Mech., 36 29–53 (2004)

Gates, ID, “Slot Coating Flows: Feasibility, Quality.” Ph.D. Thesis, University of Minnesota, Minneapolis, United States (1999)

Ruschak, KJ, “Boundary Conditions at a Liquid/Air Interface in Lubrication Flows.” J. Fluid Mech., 119 107–120 (1982)

Landau, L, Levich, B, “Dragging of a Liquid by a Moving Plate.” Acta Physiochim. URSS, 17 141–153 (1942)

Phillips, GO, Williams, PA, Handbook of Hydrocolloids, 2nd edn. CRC Press, Boca Raton, FL (2009)

Acknowledgements

This research was supported by the National Research Foundation of Korea (NRF) of Korea Grant (2016R1A5A1009592) and the Ministry of Trade, Industry & Energy (MOTIE, Korea), under the Industrial Technology Innovation Program (No. 20011712).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at the 2020 International Society of Coatings Science and Technology Conference that was held virtually September 20–23, 2020.

Rights and permissions

About this article

Cite this article

Park, J.S., Yoo, T., Chun, B. et al. Operability limits for non-Newtonian liquids in dual-layer slot coating processes using the viscocapillary model. J Coat Technol Res 19, 35–47 (2022). https://doi.org/10.1007/s11998-021-00499-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-021-00499-5