Abstract

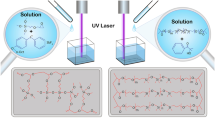

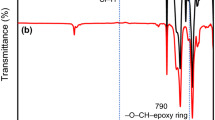

Polysiloxane is a promising modified material due to its good hydrophobicity and toughness, but it suffers from serious uneven distribution and migration during film formation process which gradually lead to the destruction of the hydrophobic structure. A novel silicon-modified copolymer with different molecular weight and vinyl content was synthesized to overcome this problem: an appropriate amount of double bonds between the polysiloxane backbone ensures uniform distribution. Moreover, a multicrosslinked network binder was prepared by miniemulsion polymerization of the polyacrylate copolymers and polysiloxane. Unlike the common crosslinked network of an uneven distribution and migration of silicone backbone, the polysiloxane with suitable crosslinking degree and molecular weight could be effectively distributed evenly during the film formation process. As a result, a better hydrophobicity and toughness performance (89.7° ± 0.5°, 2500% elongation at break) was achieved with this novel poly(methylvinylsiloxane) with 11,024 g/mol at 0.804 mmol/g vinyl content. The product was applied to pigment printing with better wet rubbing fastness and soft handle compared with the unmodified polyacrylates binder. The DSC, SAXS, and XPS indicated that high molecular organosilicon chain and moderate vinyl content were prone to phase separation and obviously shifted onto the surface of film, enriching a uniform organosilicon layer, which played a vital role in the surface hydrophobicity and mechanical properties.

Similar content being viewed by others

References

Yang, W, Zhu, L, Chen, Y, “Synthesis and Characterization of Core–Shell Latex: Effect of Fluorinated Acrylic Monomer on Properties of Polyacrylates.” J. Fluorine Chem., 157 35–40 (2014). https://doi.org/10.1016/j.jfluchem.2013.11.004

Christopher, KR, Pal, A, Mirchandani, G, Dhar, T, “Synthesis and Characterization of Polystyrene-Acrylate/Polysiloxane (PSA/PSi) Core Shell Polymers and Evaluation of Their Properties for High Durable Exterior Coatings.” Prog. Org. Coat., 77 (6) 1063–1068 (2014). https://doi.org/10.1016/j.porgcoat.2014.03.008

Lin, J, Zheng, C, Zhu, MN, Chen, YZ, Lu, PP, Liu, Q, Cai, XF, Zhuang, JW, Cai, XM, Liao, LP, Yuan, GY, Xu, CL, “Comparison of Copolymer Emulsions of Fluorine and Siloxane-Containing Acrylates with Core–Shell Structure for Water-Repellent Cotton Fabrics Coatings.” Polym. Adv. Technol., 26 (1) 68–76 (2015). https://doi.org/10.1002/pat.3420

Lin, J, Zheng, C, Ye, WJ, Wang, HQ, Feng, DY, Li, QY, Huan, BW, “A Facile Dip-Coating Approach to Prepare SiO2/Fluoropolymer Coating for Superhydrophobic and Superoleophobic Fabrics with Self-Cleaning Property.” J. Appl. Polym. Sci., 132 (1) 41458–41467 (2014). https://doi.org/10.1002/app.41458

Li, Z, He, Z, Chen, X, Tang, Y, You, S, Chen, Y, Jin, T, “Preparation of Hydrophobically Modified Cotton Filter Fabric with High Hydrophobic Stability Using ARGET-ATRP Mechanism.” RSC Adv., 9 (43) 24659–24669 (2019). https://doi.org/10.1039/c9ra04123k

Lin, J, Chen, XY, Chen, CY, Hu, JT, Zhou, CL, Cai, XF, Wang, W, Zheng, C, Zhang, PP, Cheng, J, Gou, ZH, Liu, H, “Durably Antibacterial and Bacterially Antiadhesive Cotton Fabrics Coated by Cationic Fluorinated Polymers.” ACS Appl. Mater. Interfaces, 10 6124–6136 (2018). https://doi.org/10.1021/acsami.7b16235

Shen, J, Sun, J, Hu, Y, Kan, C, “Polysiloxane/Polyacrylate Composite Latexes with Balanced Mechanical Property and Breathability: Effect of Core/Shell Mass Ratio.” J. Appl. Polym. Sci., 134 45258 (2017). https://doi.org/10.1002/app.45258

Ciu, X, Zhong, S, Wang, H, “Emulsifier-Free Coreeshell Polyacrylate Latex Nanoparticles Containing Fluorine and Silicon in Shell.” Polymer, 48 7241–7248 (2007). https://doi.org/10.1016/j.polymer.2007.10.019

Bai, R, Qiu, T, Han, F, He, L, Li, X, “Preparation and Characterization of Inorganic-Organic Trilayer Core–Shell Polysilsesquioxane/Polyacrylate/Polydimethylsiloxane Hybrid Latex Particles.” Appl. Surf. Sci., 258 (19) 7683–7688 (2012). https://doi.org/10.1016/j.apsusc.2012.04.121

Song, Q, Yan, P, Wang, H, Zhu, X, Xu, Y, “Preparation and Characterization of Multi-layer Core–Shell Polysiloxane/PSt/PMMA Latex.” Pigment Resin Tech, 41 (6) 339–343 (2012). https://doi.org/10.1108/03699421211274243

Vlad, S, Vlad, A, Oprea, S, “Interpenetrating Polymer Networks Based on Polyurethane and Polysiloxane.” Eur. Polym. J., 38 (4) 829–835 (2002). https://doi.org/10.1016/S0014-3057(01)00233-6

Cznotka, E, Jeschke, S, Vettikuzha, P, Wiemhöfer, H-D, “Semi-interpenetrating Polymer Network of Poly(methyl methacrylate) and Ether-Modified Polysiloxane.” Solid State Ion., 274 55–63 (2015). https://doi.org/10.1016/j.ssi.2015.02.013

Rodríguez, R, de las Heras Alarcón, C, Ekanayake, P, McDonald, PJ, Keddie, JL, Barandiaran, MJ, Asua, JM, “Correlation of Silicone Incorporation into Hybrid Acrylic Coatings with the Resulting Hydrophobic and Thermal Properties.” Macromolecules, 41 (22) 8537–8546 (2008). https://doi.org/10.1021/ma8006015

Zhang, SW, Liu, R, Jiang, JQ, Bai, HY, “Film Formation and Mechanical Properties of the Alkoxysilane-Functionalized Poly(styrene-co-butyl acrylate) Latex Prepared by Miniemulsion Copolymerization.” Prog. Org. Coat., 65 56–61 (2009). https://doi.org/10.1016/j.porgcoat.2008.09.010

Luo, Y, Xu, H, Zhu, B, “The Influence of Monomer Types on the Colloidal Stability in the Miniemulsion Copolymerization Involving Alkoxysilane Monomer.” Polym., 47 4959–4966 (2006). https://doi.org/10.1016/j.polymer.2006.05.020

Ramos-Fernández, JM, Beleña, I, Romero-Sánchez, MD, Fuensanta, M, Guillem, C, López-Buendía, ÁM, “Study of the Film Formation and Mechanical Properties of the Latexes Obtained by Miniemulsion Co-polymerization of Butyl Acrylate, Methyl Acrylate and 3-Methacryloxypropyltrimethoxysilane.” Prog. Org. Coat., 75 86–91 (2012). https://doi.org/10.1016/j.porgcoat.2012.03.012

Zou, M, Wang, S, Zhang, Z, Ge, X, “Preparation and Characterization of Polysiloxane-Poly(butyl acrylate–styrene) Composite Latices and Their Film Properties.” Eur. Polym. J., 41 2602–2613 (2005). https://doi.org/10.1016/j.eurpolymj.2005.05.038

Wei, S-Q, Bai, Y-P, Shao, L, “A Novel Approach to Graft Acrylates onto Commercial Silicones for Release Film Fabrications by Two-Step Emulsion Synthesis.” Eur. Polym. J., 44 2728–2736 (2008). https://doi.org/10.1016/j.eurpolymj.2008.04.025

Lin, M, Chu, F, Guyot, A, Putaux, J-L, Bourgeat-Lami, E, “Silicone–Polyacrylate Composite Latex Particles. Particles Formation and Film Properties.” Polymer, 46 1331–1337 (2005). https://doi.org/10.1016/j.polymer.2004.11.063

Yu, Z-Q, Ni, P-H, Li, J-A, Zhu, X-L, “Miniemulsion Copolymerization of Methyl Methacrylate and Butyl Acrylate in the Presence of Vinyl Siloxane Rubber.” Colloids Surf. A Physicochem. Eng. Asp., 242 9–15 (2004). https://doi.org/10.1016/j.colsurfa.2004.04.055

ASTM D1388-14ε1, Standard Test Method for Stiffness of Fabrics. General, ASTM Committee D13 on Textile for Standardization, 1–6 (2014). https://doi.org/10.1520/d1388-14e01.

AATCC Technical Manual, Method 8, Colorfastness to Crocking: Crockmeter Method. American Association of Textile Chemists and Colorists, 21–23 (2016).

Meng, Y, Chu, J, Xue, J, Liu, C, Wang, Z, Zhang, L, “Design and Synthesis of Non-crystallizable, Low-Tg Polysiloxane Elastomers with Functional Epoxy Groups Through Anionic Copolymerization and Subsequent Epoxidation.” RSC Adv., 4 31249–31260 (2014). https://doi.org/10.1039/c4ra02293a

Boehm, P, Mondeshki, M, Frey, H, “Polysiloxane-Backbone Block Copolymers in a One-Pot Synthesis: A Silicone Platform for Facile Functionalization.” Macromol. Rapid Commun., 33 (21) 1861–1867 (2012). https://doi.org/10.1002/marc.201200365

Zundel, T, Yu, JM, De France, C, “Trimethylsilylmethyllithium: A Novel Initiator for the Anionic Polymerization of Cyclosiloxanes and Vinyl Monomers.” Macromol. Symp., 88 177–189 (1994). https://doi.org/10.1002/masy.19940880114

Chern, C-S, Chang, H-T, “Particle Nucleation and Growth Mechanisms in Miniemulsion Polymerization of Styrene.” Polym. Int., 51 1428–1438 (2002). https://doi.org/10.1002/pi.1079

Wang, L, Cui, S, Ni, H, Wu, M, Wang, W, “New Washing-Free Printing Binder Based on Organosilicon-Modified Polyacrylate for Polyester Fabric Printing of Disperse Dyes.” Prog. Org. Coat., 123 75–81 (2018). https://doi.org/10.1016/j.porgcoat.2018.06.009

Ge, C, Wu, Y, Xu, J, “Stability and Optimum Polymerized Condition of Polysiloxane-Polyacrylate Core/Shell Polymer.” Adv. Polym. Tech., 9 161–172 (2010). https://doi.org/10.1002/adv.20182

Li, X, Zhao, Y, Li, H, Yuan, X, “Preparation and Icephobic Properties of Polymethyltrifluoropropylsiloxane-Polyacrylate Block Copolymers.” Appl. Surf. Sci., 316 222–231 (2014). https://doi.org/10.1016/j.apsusc.2014.07.097

Guo, L, Jiang, S, Qiu, T, Zhang, S, He, L, Tan, J, Li, X, “Miniemulsion Polymerization of Fluorinated Siloxane-Acrylate Latex and the Application as Waterborne Textile Finishing Agent.” J. Appl. Polym. Sci., 131 (8) 40162 (2014). https://doi.org/10.1002/app.40162

Hu, J, Lin, J, Zhang, Y, Lin, Z, Qiao, Z, Liu, Z, Yang, W, Liu, X, Dong, M, Gou, Z, “A New Anti-biofilm Strategy of Enabling Arbitrary Surfaces of Materials and Devices with Robust Bacterial Anti-adhesion via a Spraying Modified Microsphere Method.” J. Mater. Chem. A, 7 26039–26052 (2019). https://doi.org/10.1039/C9TA07236E

Acknowledgments

This study was kindly supported by the Zhejiang Provincial Top Key Academic Discipline of Chemical Engineering and Technology of Zhejiang Sci-Tech University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Q., Wu, M. Structure of vinyl polysiloxane on properties of polyacrylates film and its pigment printing application. J Coat Technol Res 17, 937–948 (2020). https://doi.org/10.1007/s11998-020-00320-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-020-00320-9